Full-width manufacturing method of diamond picture

A production method and diamond painting technology, which are applied in chemical instruments and methods, solid separation, and processes for producing decorative surface effects, etc. Small gap, improve the effect of the picture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0048] Specific embodiment one: a kind of diamond painting full frame production method, comprises the following steps successively:

[0049] A, drawing paper positioning, such as figure 2 , Figure 8 As shown, the drawing paper 9 is positioned using the substrate 5 for positioning, the drawing paper is pasted on the surface of a substrate, the drawing paper has been positioned on the substrate, and the upper surface of the drawing paper has an adhesive layer 10. In this embodiment, the drawing paper The upper surface is pasted with double-sided tape, which constitutes the adhesive layer. The color of the drawing paper can be selected as required, for example, red drawing paper or white drawing paper or drawing paper of other colors.

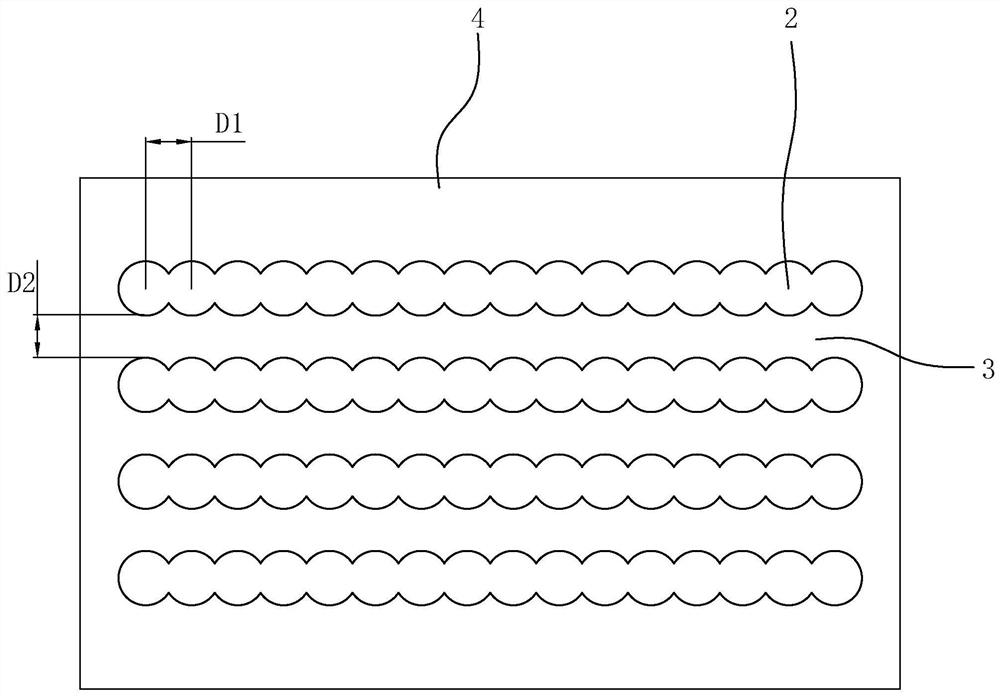

[0050] Sieve drill sieve drill, sieve drill sieve drill includes single-row template sieve drill and double-row template sieve drill.

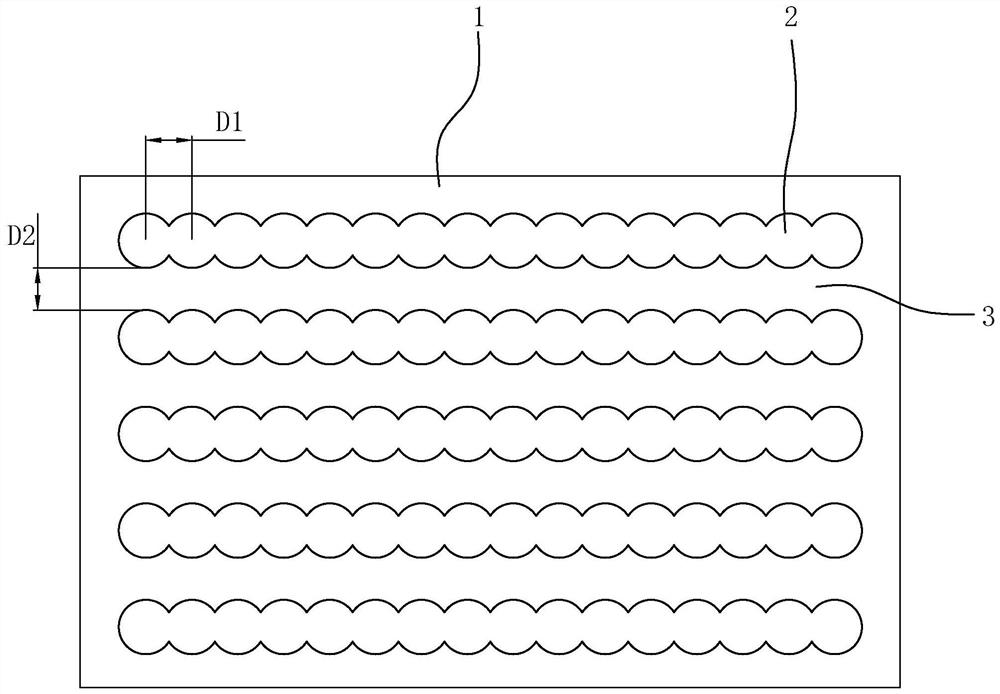

[0051] Such as figure 1 As shown, the single-row formwork sieve drill uses a sieve drilling machine to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com