Cylinder cover oil sprayer hole ring groove coaxiality detection device

A technology of injector hole and detection device, which is applied to measurement devices, instruments, etc., achieves the effects of high compatibility, avoidance of scratches, and easy disassembly and replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

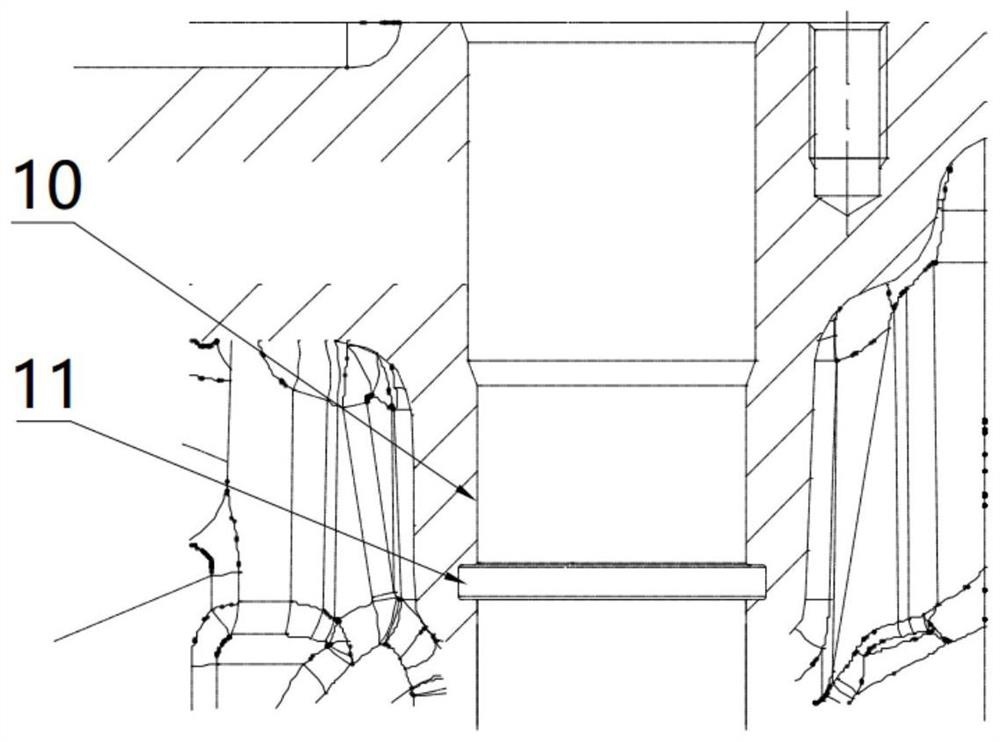

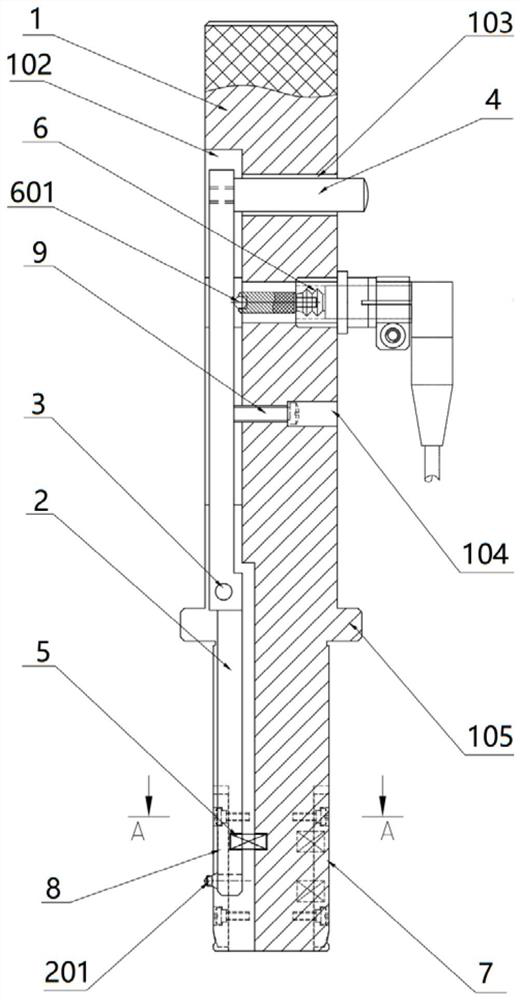

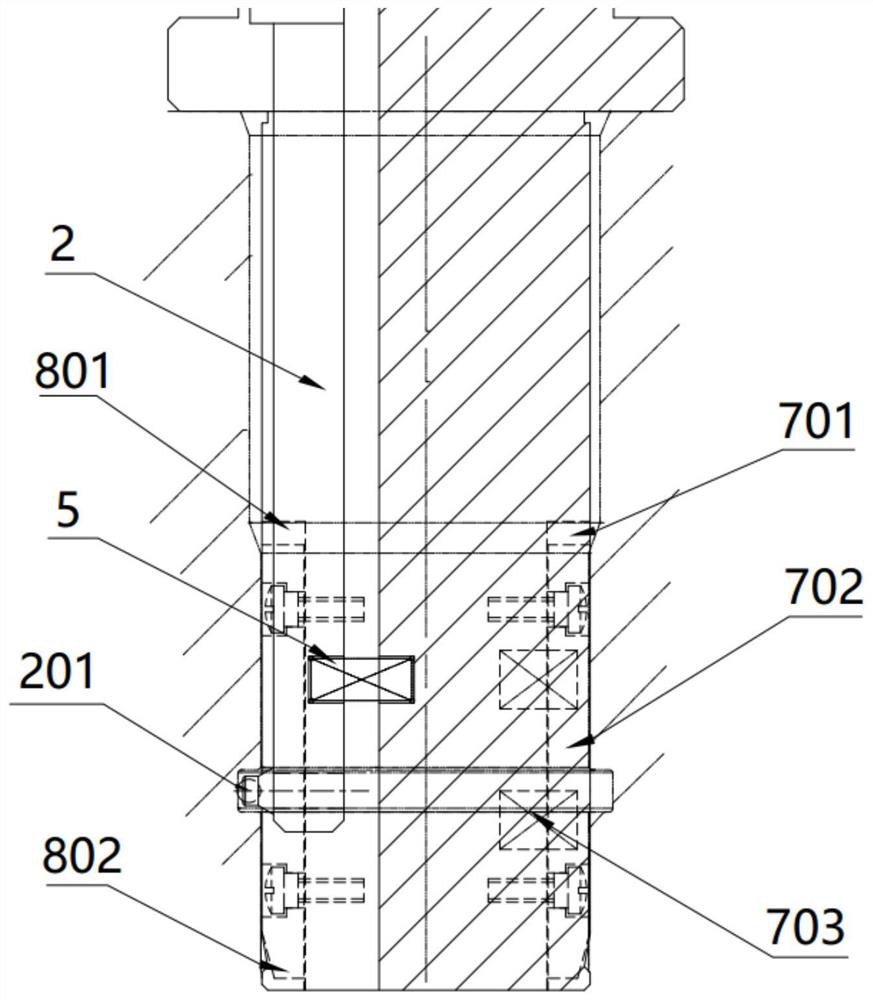

[0028] According to a specific embodiment of the program, a cylinder head fuel injector annular groove coaxiality detection device, such as Figure 1-4 As shown, it includes a mandrel 1 and a measuring head 201 arranged at the lower part of the mandrel 1 for measuring the injector annular groove 11. The main point is that a core expansion mechanism 7 is provided on the outer surface of the lower part of the mandrel 1 , the core expansion mechanism 7 is a movable mechanism that can be tightened and condensed by an external force, so that the core expansion mechanism 7 can match the inner diameter of the injector hole 10 . The positioning part of the detection device is equipped with a mechanism with the function of expanding the core, and the circular arc and the inner diameter of the injector hole 10 are used for expansion and positioning. It is not necessary to replace the positioning mandrel or positioning sleeve during use, and the inspection tool and the workpiece can also ...

Embodiment 2

[0034] On the basis of Embodiment 1, this embodiment further optimizes the operation mode of the device, the specific differences are: as figure 1As shown, a third vertical groove 102 is vertically opened on one side of the mandrel 1, and a swing rod 2 is arranged in the third vertical groove 102, and the middle part of the swing rod 2 is connected with the first fastening pin 3 The sidewalls of the three vertical grooves 102 are hinged, and a gap for making way for the swing rod 2 to rotate is provided between the fork 2 and the third vertical groove 102; The top of 1 is provided with a transverse groove 103, and an extruding rod 4 is arranged in the transverse groove 103. One end of the extruding rod 4 is connected to the upper part of the swing rod 2, and the other end extends out of the mandrel 1; The second compression spring 5 is arranged in the gap between the lower part of the swing rod 2 and the third vertical groove 102; The outer lateral extension, by pressing or l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com