Feeding device for livestock breeding

A feeding device and processing device technology, applied in the field of breeding, can solve problems such as residual adhesion, difficulty in cleaning, and reduction of breeding efficiency and results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

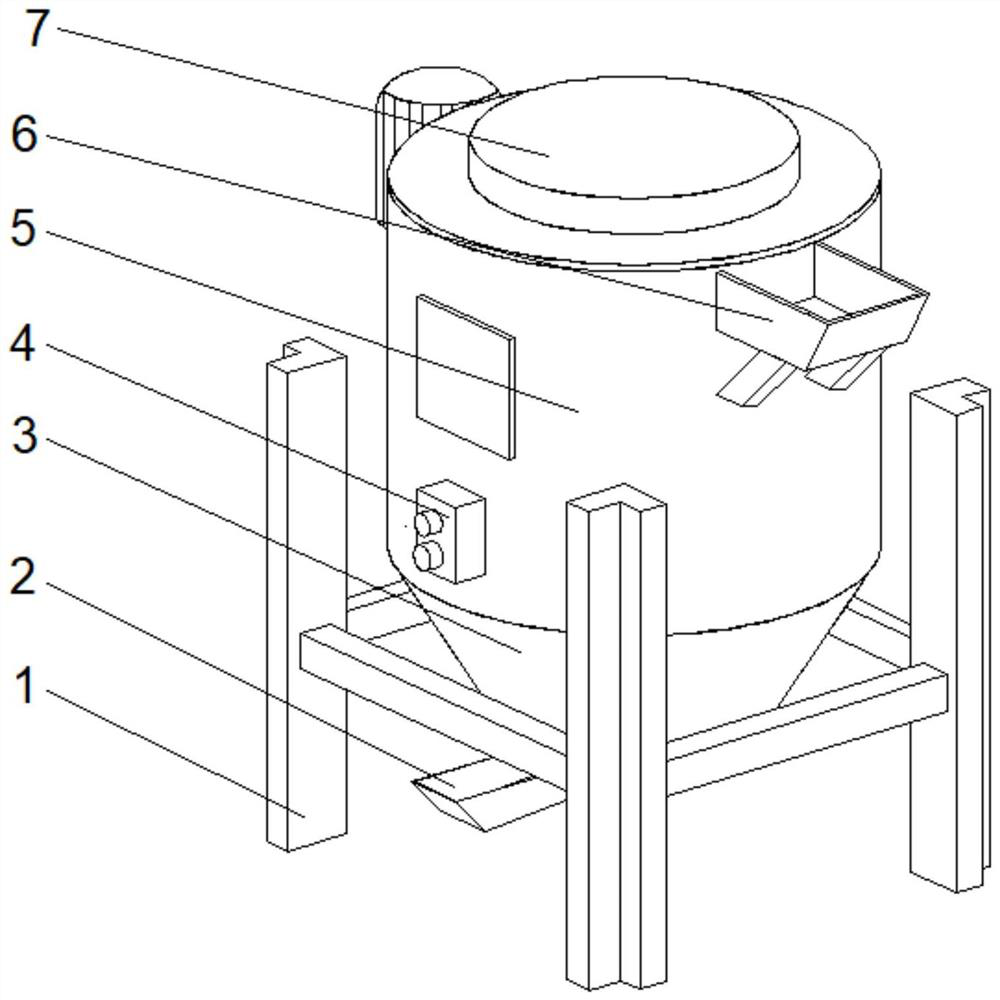

[0033] see Figure 1-2 , the present invention provides a technical solution: a feeding device for animal husbandry, including a collection box 3, the bottom of the collection box 3 is provided with a discharge port 2, and the middle part of the outer wall on both sides of the collection box 3 is fixedly connected with a fixed frame 1, The top of the collection box 3 is fixedly connected with a processing device 5, the middle position of the front bottom of the processing device 5 is fixedly connected with a controller 4, the top right side of the processing device 5 is provided with a feed inlet 6, and the middle position of the top of the processing device 5 is provided with a drive7.

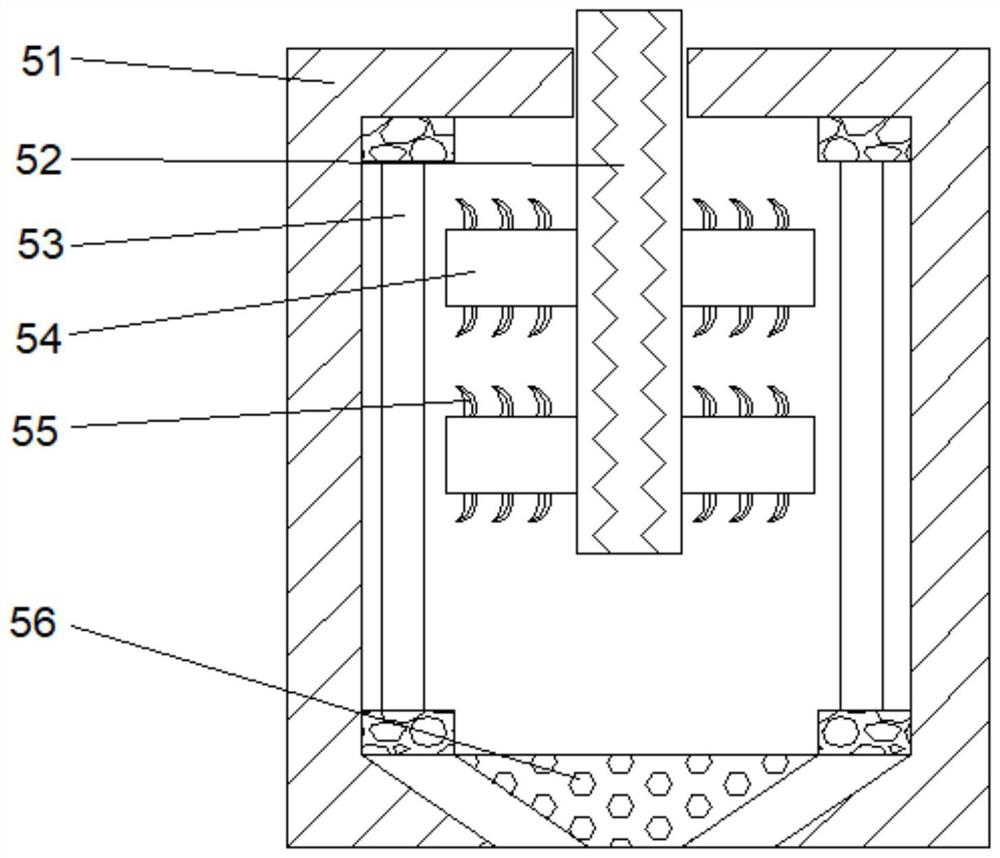

[0034] Wherein, the processing device 5 includes a processing tank 51, the middle position of the inner cavity bottom of the processing tank 51 is provided with a collecting port 56, and the inner cavity bottom of the processing tank 51 is fixedly connected with a cleaning mechanism 53 at bot...

Embodiment 2

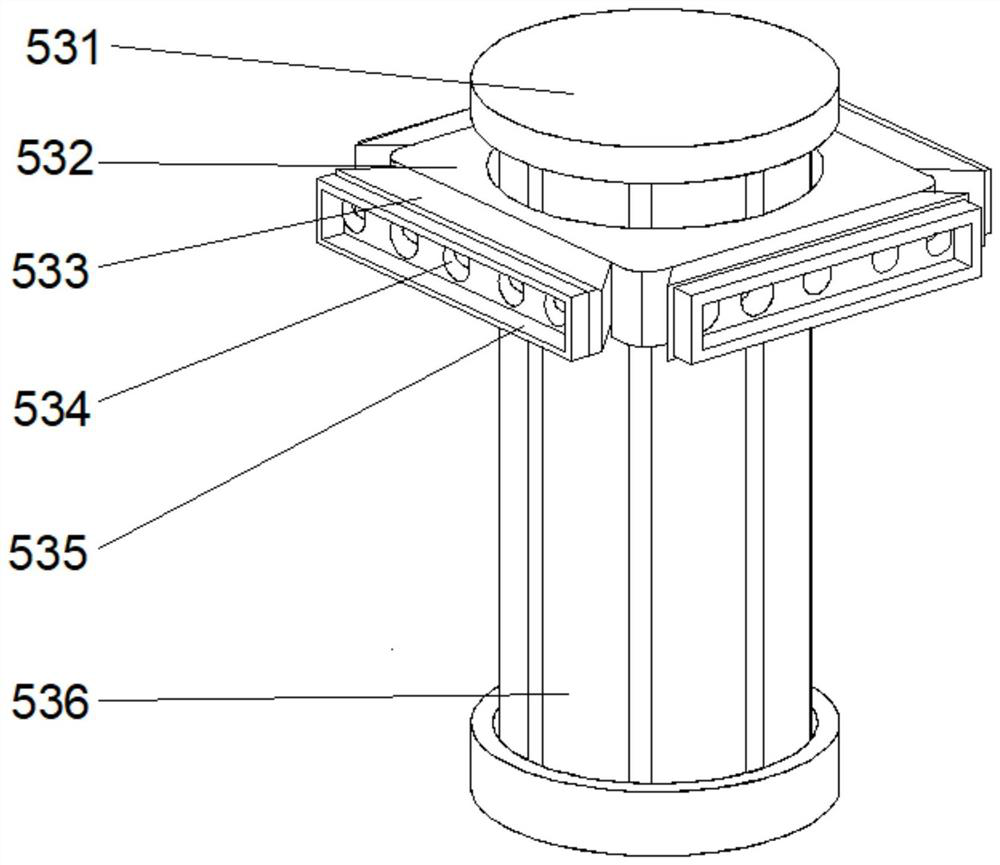

[0037] see Figure 1-4, on the basis of Embodiment 1, the present invention provides a technical solution: the cleaning mechanism 53 includes a support column 536, the two ends of the support column 536 are fixedly connected to the limit block 531, and the top outer surface of the support column 536 is provided with a moving block 532 The outer walls on both sides of the moving block 532 are fixedly connected with an auxiliary mechanism 533, and the side of the auxiliary mechanism 533 away from the support column 536 is fixedly connected with a scraper 535, and the middle part of the side of the auxiliary mechanism 533 away from the support column 536 is provided with a cleaning port 534.

[0038] Among them, the auxiliary mechanism 533 includes a frame d1, a through hole d7 is opened in the middle of the bottom of the inner cavity of the frame d1, side plates d2 are fixedly connected to the inner walls of both sides of the frame d1, and an upper plate is fixedly connected to t...

Embodiment 3

[0041] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the linkage mechanism d6 includes a linkage frame d62, the two sides of the linkage frame d62 are fixedly connected with a linkage plate d61, and the top of the linkage plate d61 is fixedly connected with a The carrying plate d63, the top of the carrying plate d63 is fixedly connected with the push block d64, the middle position of the top of the linkage frame d62 is fixedly connected with the partition d65, the bottom of the partition d65 is provided with a communication port d66, and the partition d65 is located on the two sides of the communication port d66. The side is fixedly connected with guide block d67.

[0042] Wherein, the bearing plate d63 includes a contraction plate t4, and the two sides of the bottom of the contraction plate t4 are fixedly connected with a force-bearing block t3, and the middle position of the top of both sides of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com