Domestic compaction device suitable for making bean curd

A compaction device and tofu technology, which are applied in the application, dairy products, cheese substitutes and other directions to achieve the effects of increasing compaction, improving safety and hygiene, and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

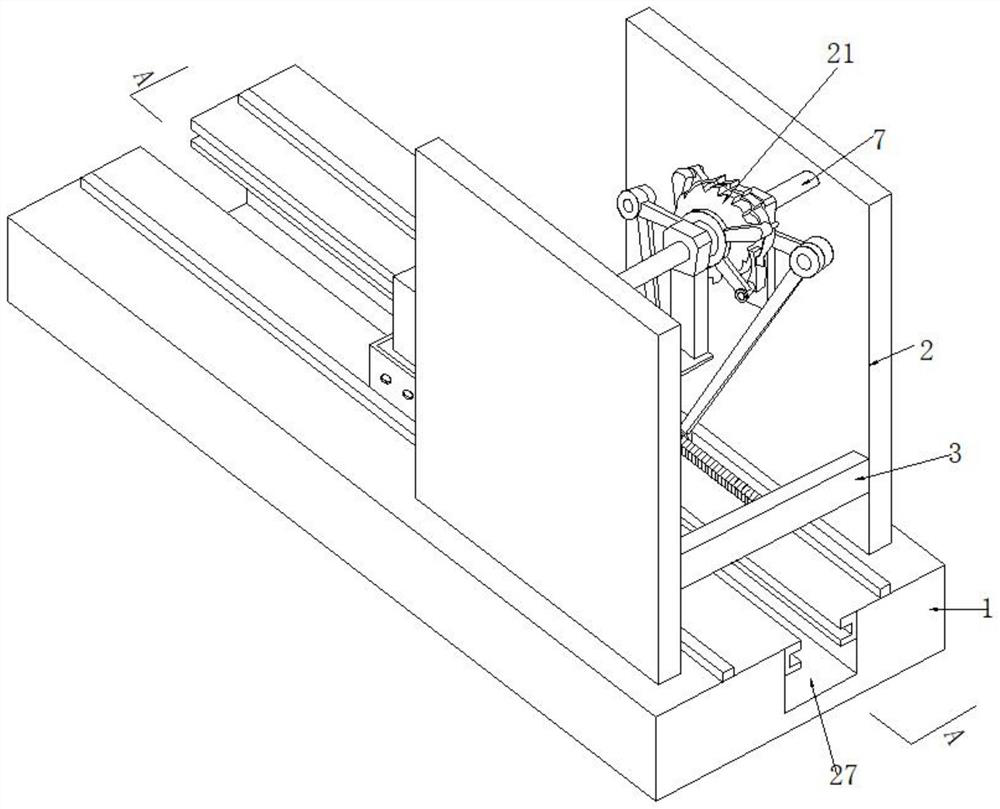

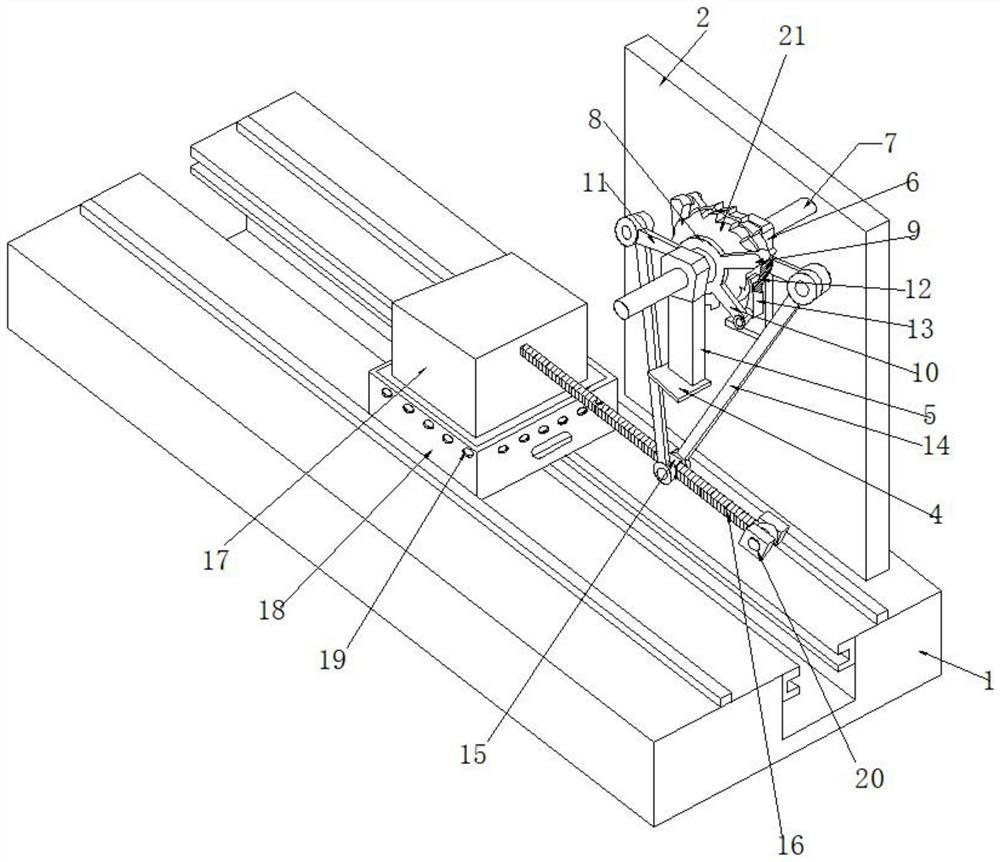

[0031] like Figure 1-2 and Image 6 displayed in:

[0032]The present invention provides a compacting device suitable for making tofu at home. Its structure includes a workbench 1, and the two ends of the top side of the workbench 1 are provided with fixing plates 2, and between the two ends of the fixing plates 2 A horizontal plate 3 is provided across the lower part of one side, and a support plate 4 is provided at the center of the corresponding side of the fixed plate 2 at both ends. The top of the support plate 4 and one end away from the fixed plate 2 are provided with A support column 5, the top of the support column 5 is provided with a fixed column 6, and the middle part of the fixed column 6 is provided with a shaft rod 7, and the end of the shaft rod 7 and close to the fixed plate 2 is inserted into the The upper part of the center of the fixed plate 2 extends to the other side of the fixed plate 2 and is connected to a driver, and the driver is installed on the ...

Embodiment 2

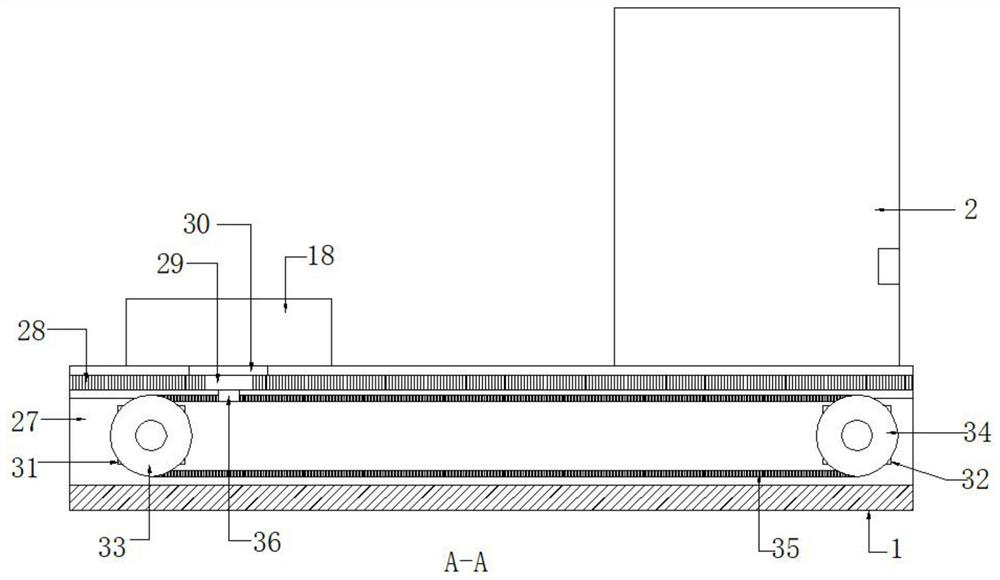

[0036] like Figure 3-5 displayed in:

[0037] The present invention provides a compacting device suitable for making tofu at home. Its structure includes a workbench 1, and the two ends of the top side of the workbench 1 are provided with fixing plates 2, and between the two ends of the fixing plates 2 A horizontal plate 3 is provided across the lower part of one side, and a support plate 4 is provided at the center of the corresponding side of the fixed plate 2 at both ends. The top of the support plate 4 and one end away from the fixed plate 2 are provided with A support column 5, the top of the support column 5 is provided with a fixed column 6, and the middle part of the fixed column 6 is provided with a shaft rod 7, and the end of the shaft rod 7 and close to the fixed plate 2 is inserted into the The upper part of the center of the fixed plate 2 extends to the other side of the fixed plate 2 and is connected with a driver, and the driver is installed on the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com