Adjustable mouth plate

A mouth-plate and mouth-adjusting technology, applied in tires, household appliances, other household appliances, etc., can solve the problems of low adjustment accuracy, decreased sealing performance of the mouth-plate, and high maintenance costs, and achieves improved accuracy and flexibility. The effect of reducing the difficulty of maintenance and solving the problem of glue leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

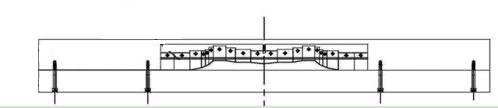

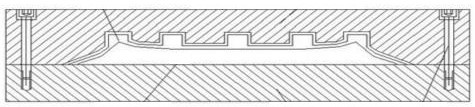

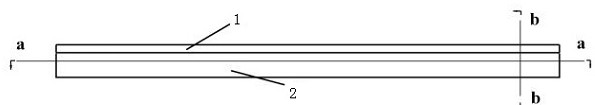

[0029] like Figure 3-5 As shown, the present invention provides an adjustable mouth plate, including a cover plate 1 and a chassis 2 made of a solid metal plate. The chassis 2 is provided with four upwardly protruding sides 3, and the chassis 2 is provided with a penetrating The hole 4 of the hole 4 is provided with an upwardly protruding boss 5 on the side of the hole 4; the hole 4 of the same shape is also provided on the cover plate 1 corresponding to the hole 4 on the chassis 2, and the side of the hole 4 of the cover plate 1 Also be provided with boss 5 on. As the maximum passing area of the die plate, the hole 4 takes into account the functions of the die plate and the pre-die plate.

[0030] The cover plate 1 is detachably fixedly connected above the chassis 2 by screws 11, and is used to close and protect the structure on the chassis 2. There is a gap between the boss 5 of the cover plate 1 and the boss 5 of the chassis 2; it also includes a deformable The sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com