Overhead, cable-free and high-load-bearing charging pile and intelligent parking system

A charging pile, high-load-bearing technology, applied in the field of charging piles and intelligent parking systems, can solve the problems of shortened service life, inconsistent thread pressure, thick charging cable, etc., and achieves improved service life, good locking effect, and smooth push. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

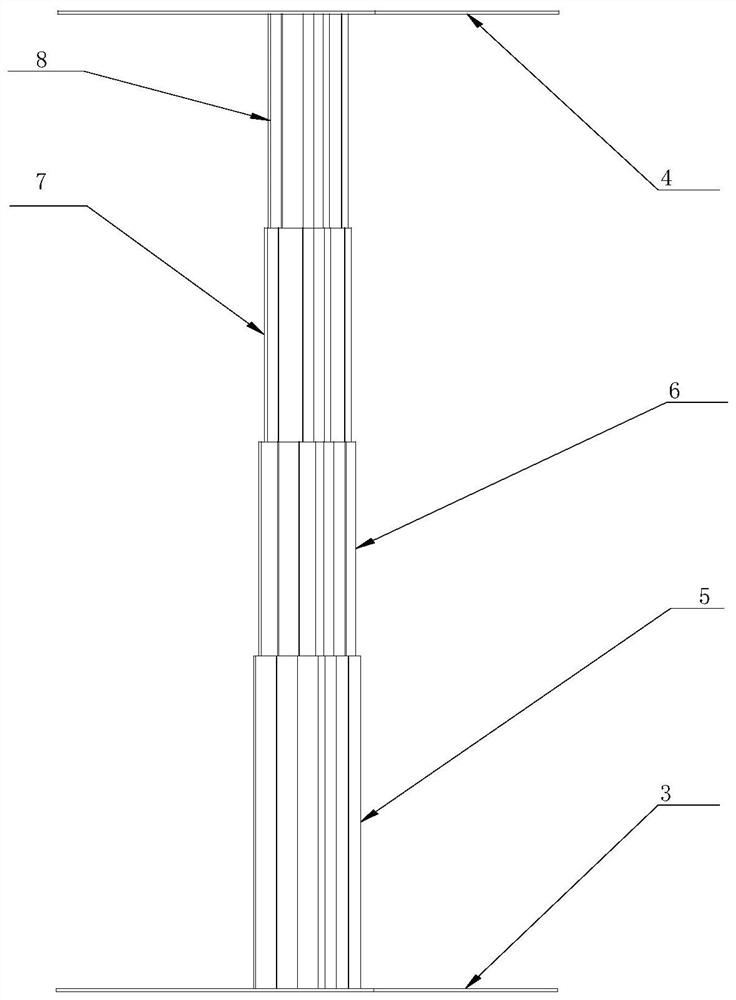

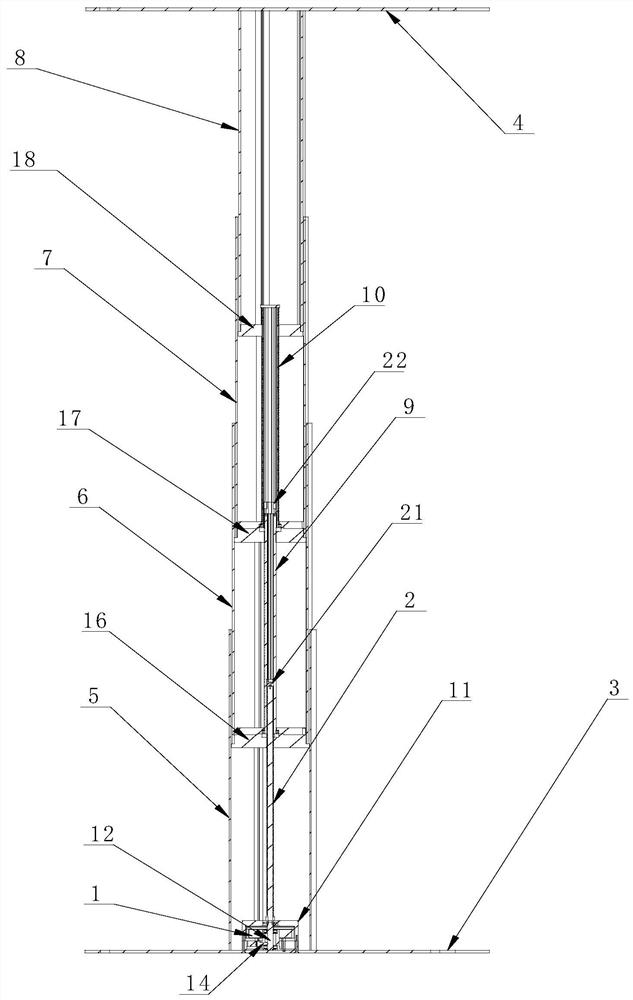

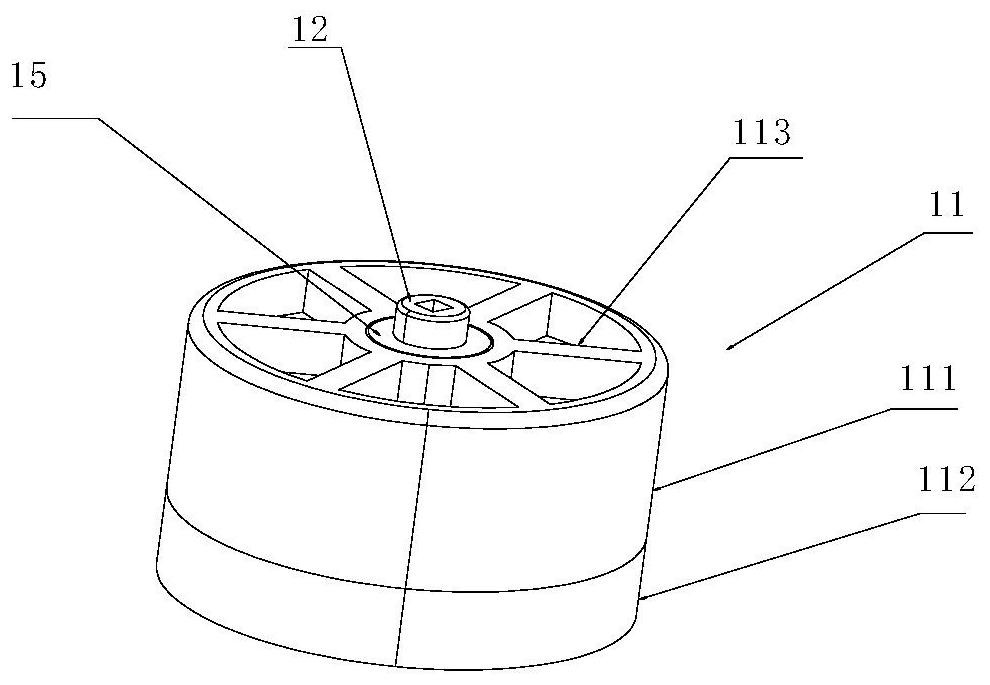

[0057] see Figure 1-9 , an overhead, cable-free, high-load charging pile, including a motor 1, a first screw rod 2; a first fixing plate 3, a second fixing plate 4, a first sleeve 5, a second sleeve 6, The third sleeve 7, the fourth sleeve 8, the second screw mandrel 9, the third screw mandrel 10, the motor box 11 is fixed on the first fixing plate 3, and the motor 1 is fixed in the motor box 11 , the bottom of the first screw mandrel 2 is coaxially fixedly connected with a driving rod 12, and the driving rod 12 is connected to the motor 1 in transmission, and the driving rod 12 is provided with a locking part 13, and the motor box 11 is provided with There is a locking fitting part 14 that cooperates with the locking part 13; the upper surface of the driving rod 12 and the motor box 11 is connected by a plane thrust bearing 15;

[0058] The first sleeve 5, the second sleeve 6, the third sleeve 7, and the fourth sleeve 8 are sequentially socketed from bottom to top, the firs...

Embodiment 2

[0088] It is substantially the same as Embodiment 1, except that the conductive member is implemented in another form. Specifically, the conductive member includes the outer walls of the second sleeve 6, the third sleeve 7, and the fourth sleeve 8. The first conductive strip 41 and the second conductive strip 42 arranged on the inner walls of the first sleeve 5, the second sleeve 6, and the third sleeve 7, the second conductive strip 42 of the first sleeve 5 and the second sleeve The first conductive strip 41 of the sleeve 6 is electrically connected, the second conductive strip 42 of the second sleeve 6 is electrically connected with the first conductive strip 41 of the third sleeve 7, and the second conductive strip 42 of the third sleeve 7 is electrically connected to the first conductive strip 41 of the third sleeve 7. The first conductive strip 41 of the four sleeves 8 is electrically connected, the second conductive strip 42 of the first sleeve 5 is electrically connected...

Embodiment 3

[0093] refer to Figure 11 and Figure 12 , an intelligent parking system, comprising a parking space 100, a controller 200, a pair of charging piles 300 described in Embodiment 1 arranged on both sides of the entrance of the parking space 100, a remote server 400, and an APP 500;

[0094] A display screen 600 is fixed between the two second fixing plates, and the display screen 600 is electrically connected to the conductive member; the first fixing plate is fixed on the top of the top wall of the parking space.

[0095] The remote server 400 is communicated with the controller 200, and the user sends a control command to the remote server 400 by logging into the APP 500 to perform payment operations;

[0096] The charging interface is connected with a charging gun 700 for charging the electric vehicle;

[0097] The motor, the display screen 600 and the charging gun 700 are electrically connected to the controller 200 .

[0098] The parking system of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com