Needle tube type heat-conducting silicone grease placing device without manual operation

A heat-conducting silicone grease, a technology that does not require labor, is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., and can solve problems such as appearance impact, inconvenient bagging, and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

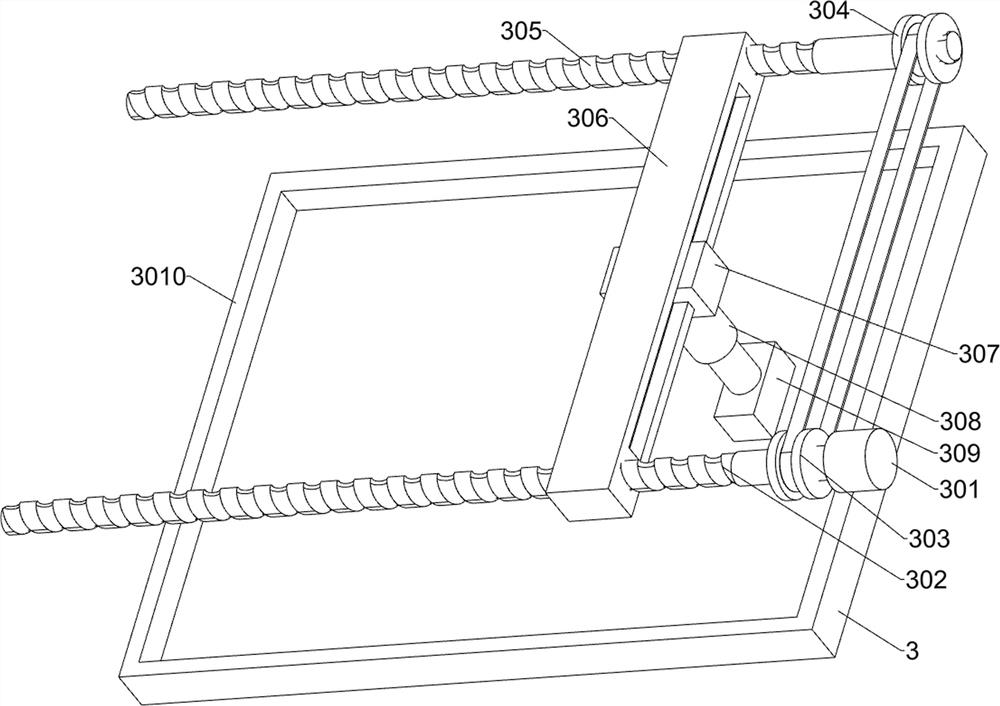

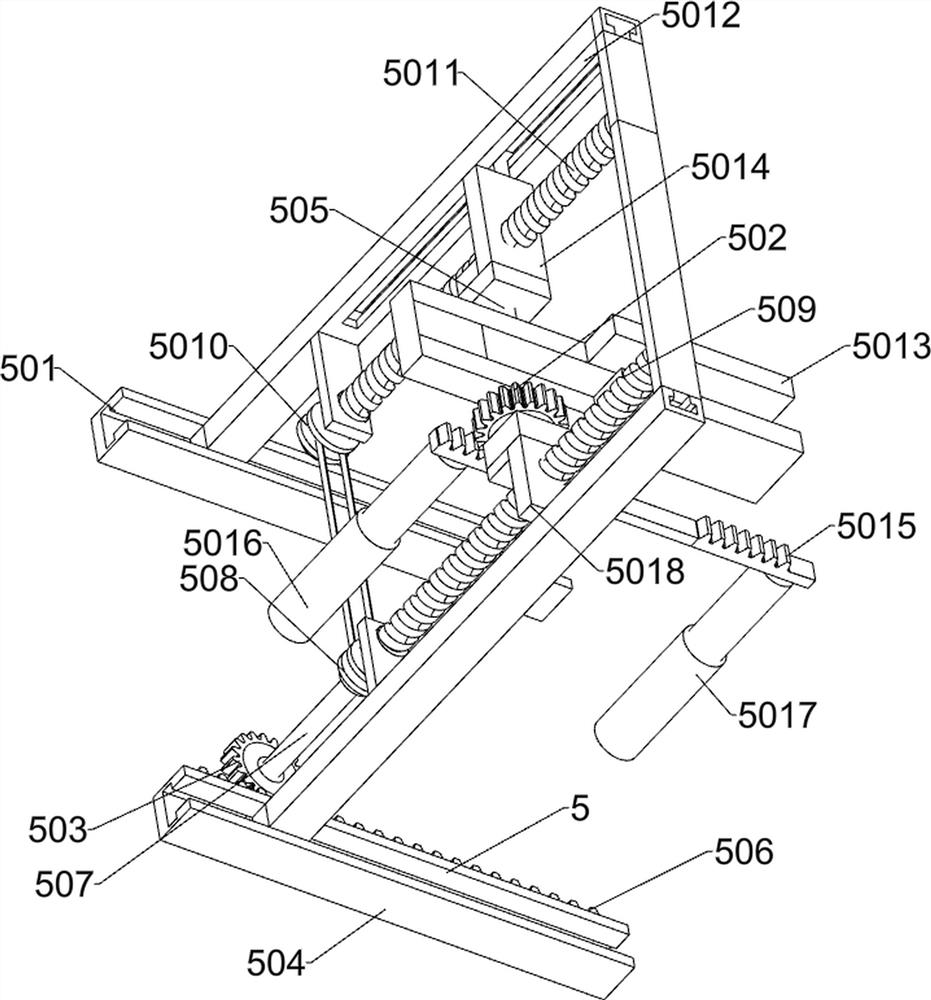

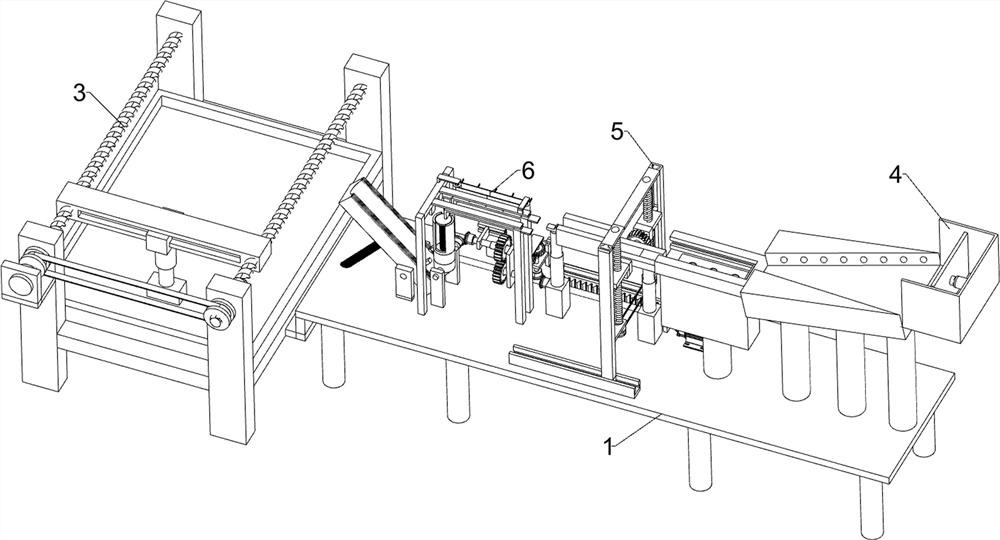

[0028] A needle-type heat-conducting silicone grease placement device without manual operation, such as Figure 1-7 As shown, it includes workbench 1, control panel 2, placement mechanism 3, limit mechanism 4, unloading mechanism 5 and sorting mechanism 6; workbench 1 is connected with control panel 2; workbench 1 is connected with placement mechanism 3 ; The workbench 1 is connected with the limit mechanism 4; the workbench 1 is connected with the blanking mechanism 5; the workbench 1 is connected with the sorting mechanism 6.

[0029] Working principle: When the device is used, first place the needle-type heat-conducting silicone grease manually on the limit mechanism 4, then open and adjust the device through the control panel 2 on the workbench 1, and then pass the needle-type heat-conducting silicon grease through the limit mechanism 4. The grease is limited and stored, and the needle-type heat-conducting silicone grease is transported to the unloading mechanism 5 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com