Silencing micro-resistance slow-closing butterfly check valve

A check valve and slow-closing technology, which is applied in the field of sound-absorbing micro-resistance slow-closing butterfly check valves, can solve the problems of noise generation and inability to filter impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

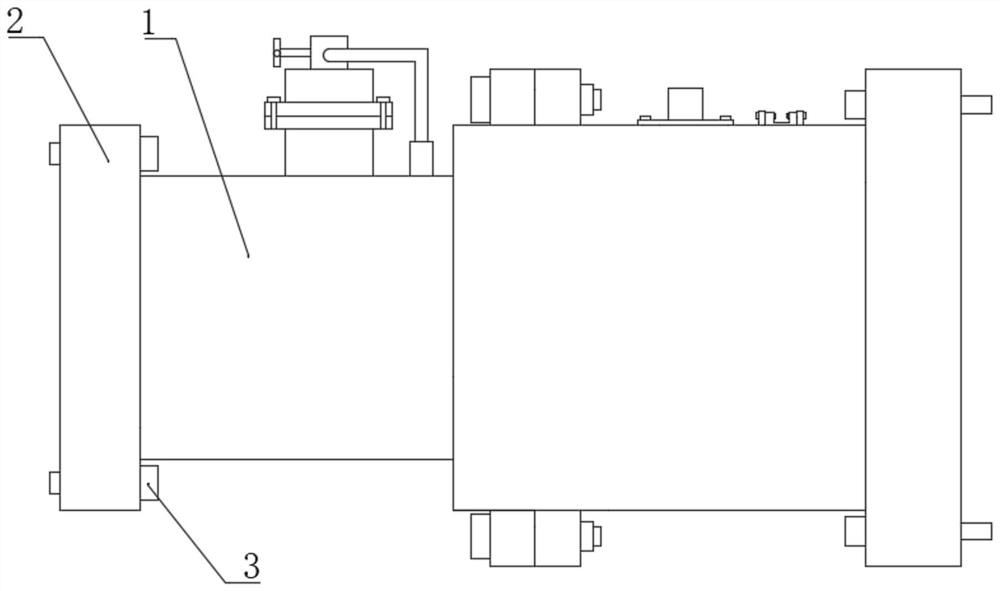

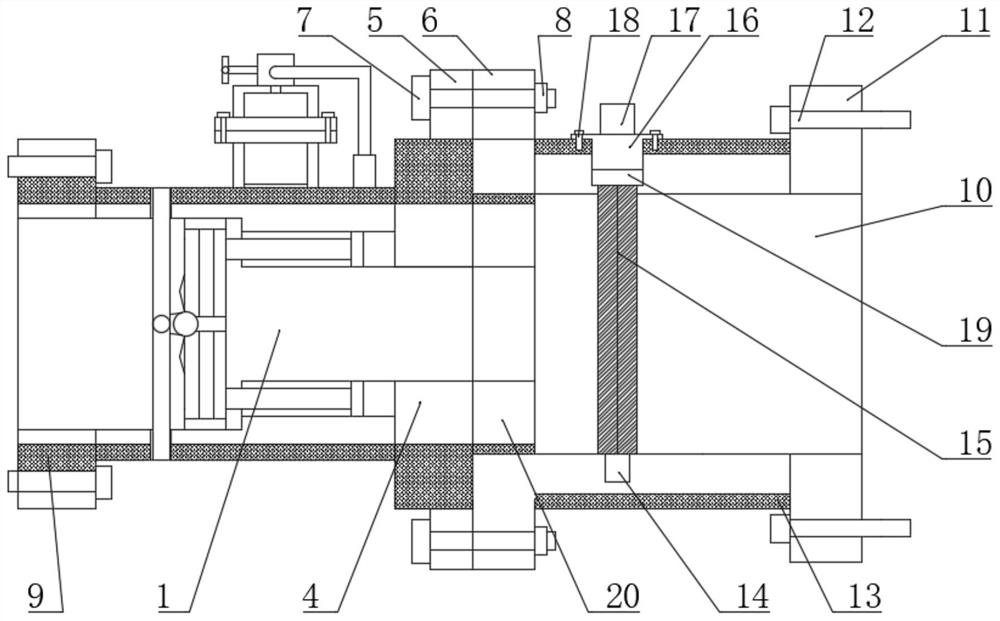

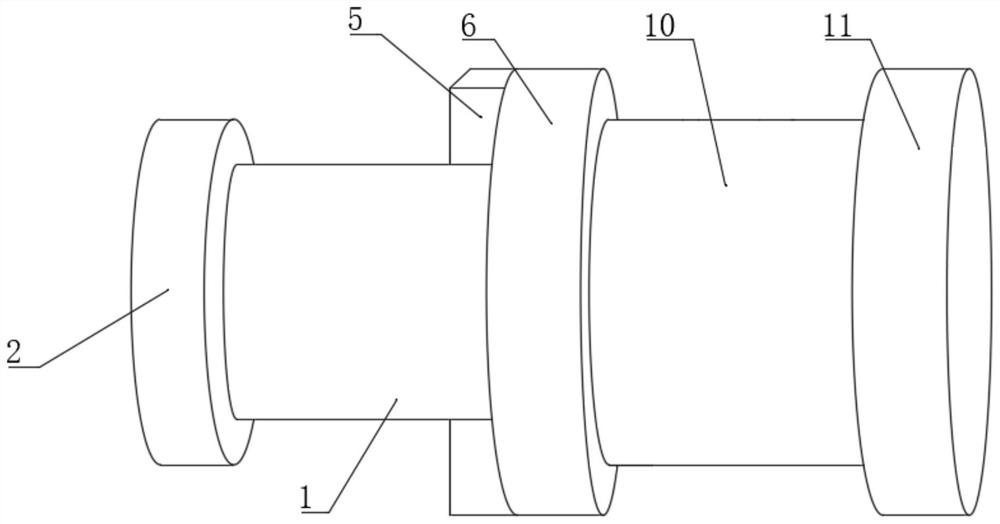

[0020] see Figure 1-3 , the present invention provides the following technical solutions: a slow-closing butterfly check valve with noise reduction and micro-resistance, including a check valve 1, and both sides of the check valve 1 are fixedly connected with a first flange 2 and a second flange Disc 4, one side of the second flange 4 is fixedly connected with a protrusion 20, the outer surface of the protrusion 20 is threadedly connected with a connecting pipe 10, and the two sides of the connecting pipe 10 are respectively fixedly connected with the third flange 6 and the second flange. Four flanges 11, the bottom of the inner wall of the connecting pipe 10 is provided with a draw-in groove, the bottom of the inner wall of the draw-in groove is overlapped with a connection block 14, and the top of the connection block 14 is fixedly connected with a filter plate 15, and the number of filter plates 15 is two. Through the setting of the filter plate 15, the impurities in the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com