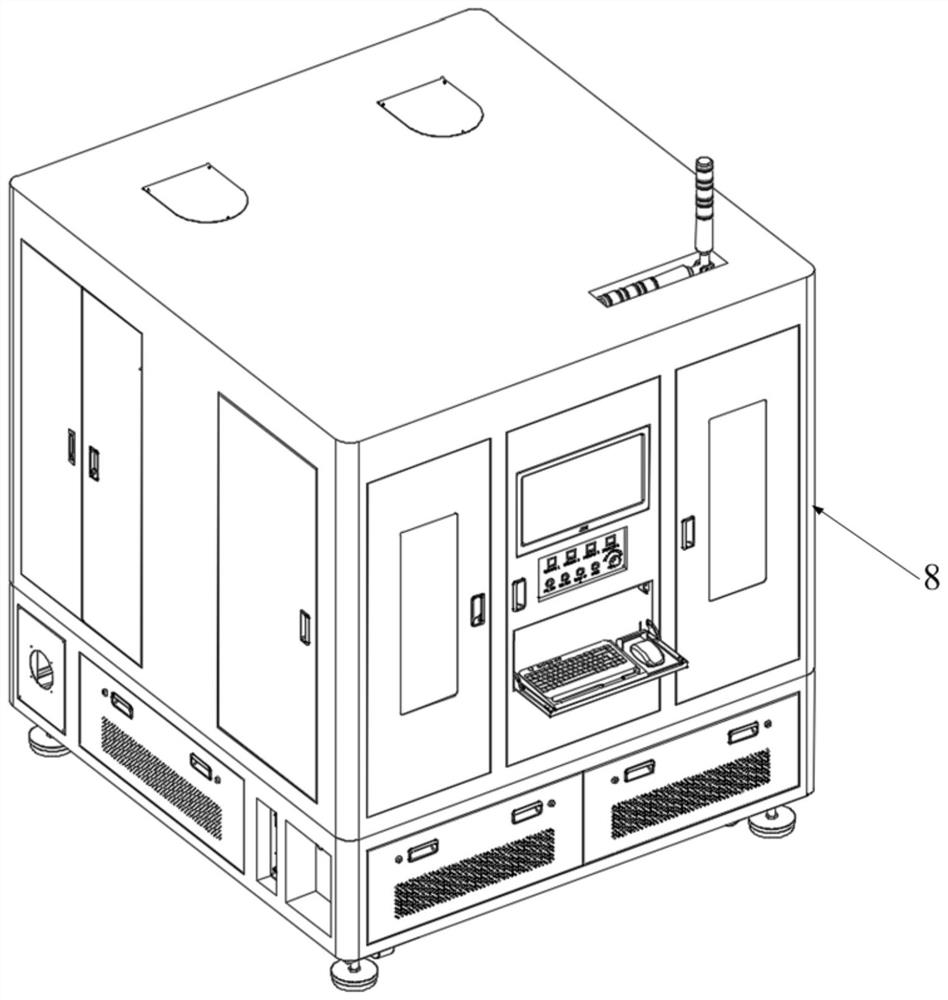

Full-automatic camera multifunctional testing equipment

A multi-functional test and camera technology, applied in image communication, television, electrical components, etc., can solve the problems of low test efficiency, low economic benefit, high labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

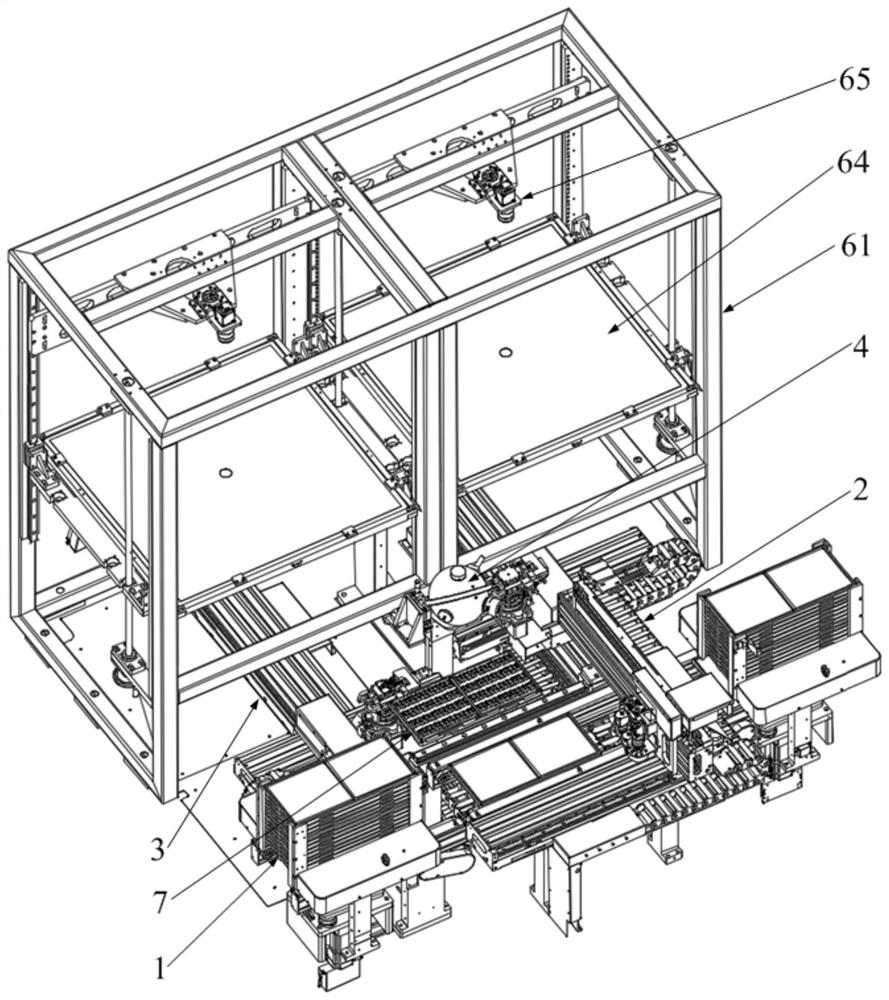

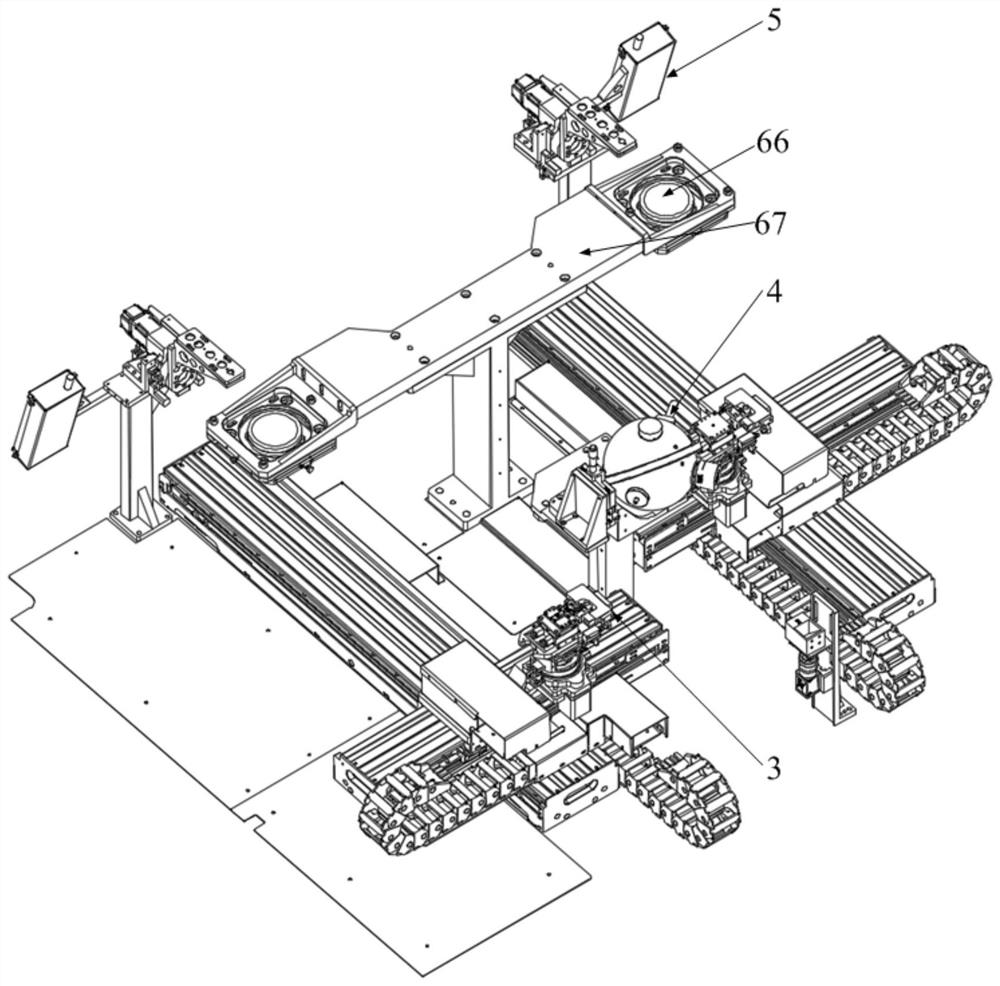

[0059] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0060] refer to Figures 1 to 11 As shown, the present invention provides a fully automatic camera multifunctional testing device, including a loading and unloading storage device 1, a material transfer device 2 arranged close to the loading and unloading storage device 1, and several jigs arranged on one side of the loading and unloading storage device 1 device 3, and the LIV test device 4 arranged above one end of several fixture devices 3; an eye safety test device 5 is also arranged above the other end of each fixture device 3, and the upper middle part of each fixture device 3 is also A speckle test device 6 is provided; the material transfer device 2 is used to transfer the product to be tested on the loading and unloading storage device 1 to the fixture device 3, and the fixture device 3 is used to transfer the products to the LIV in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com