Electronic substrate and manufacturing method thereof

A technology for electronic substrates and manufacturing methods, which is applied in the fields of printed circuit manufacturing, assembly of printed circuits with electric components, and bendable/stretchable parts of circuits, etc., which can solve the problem of signal transmission efficiency, poor transmission quality, and more connections And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

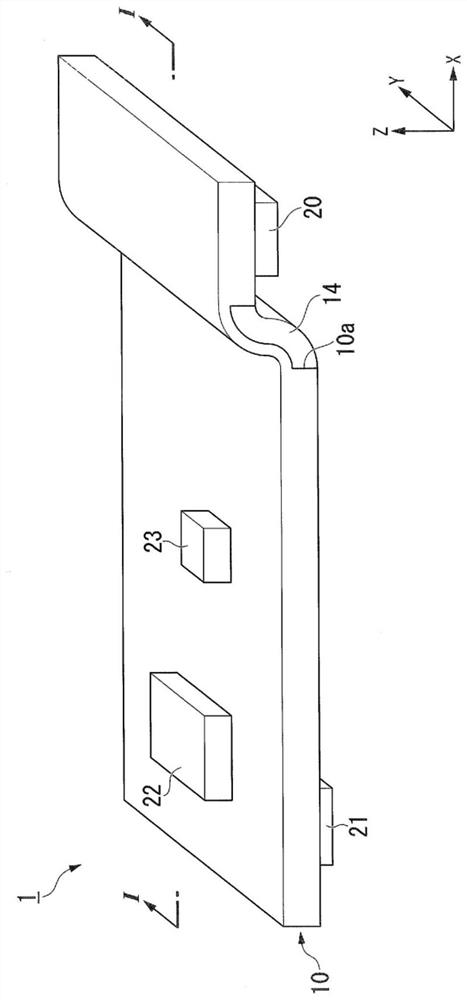

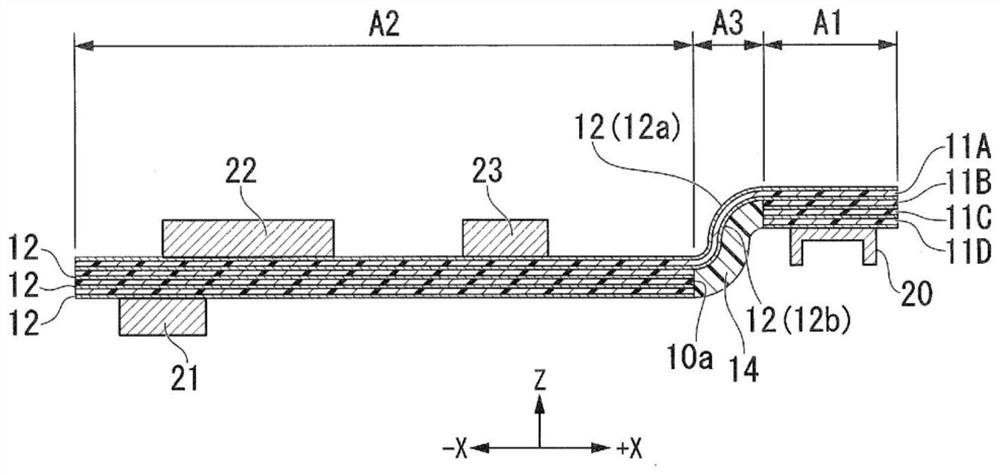

[0025] Hereinafter, the electronic substrate of this embodiment will be described based on the drawings.

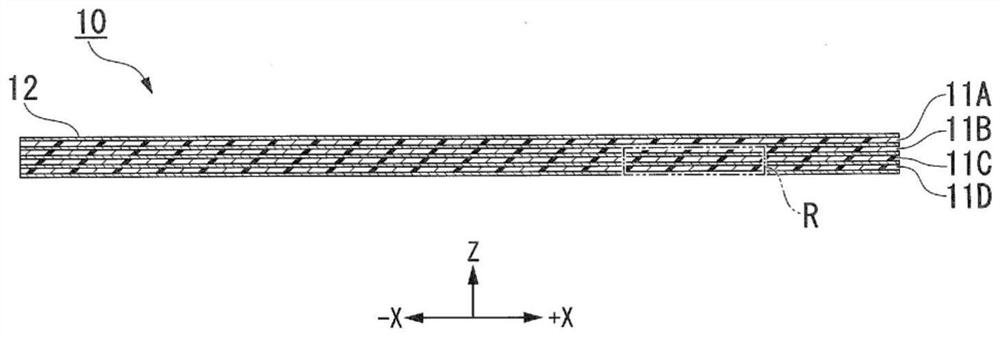

[0026] Such as Figure 1A As shown, the electronic substrate 1 is a substrate with a connector including a substrate main body 10 and a connector 20 . The substrate main body 10 may be an SSD (Solid State Drive) or a wireless communication substrate. Such as Figure 1B As shown, the substrate main body 10 is constituted by laminating a plurality of insulating layers 11A to 11D having conductive layers 12 on their surfaces. Each conductor layer 12 may be a printed circuit wiring for transmitting electrical signals, or may be a GND layer. Conductive layers 12 may be electrically connected to each other through via holes or the like. The insulating layers 11A to 11D are adhered and fixed to each other by an unillustrated adhesive layer.

[0027] The connector 20 is mounted on the board main body 10 . In addition, electronic components 21 to 23 are mounted on the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com