An improved mulberry bud grafting process based on sheet bud grafting

An improved bud grafting technology, which is applied in grafting, cultivation, agriculture, etc., can solve problems affecting the supply of grafted mulberry seedlings and the decline in the total amount of grafted mulberry seedlings, and achieve the effects of improving grafting efficiency, long grafting period, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

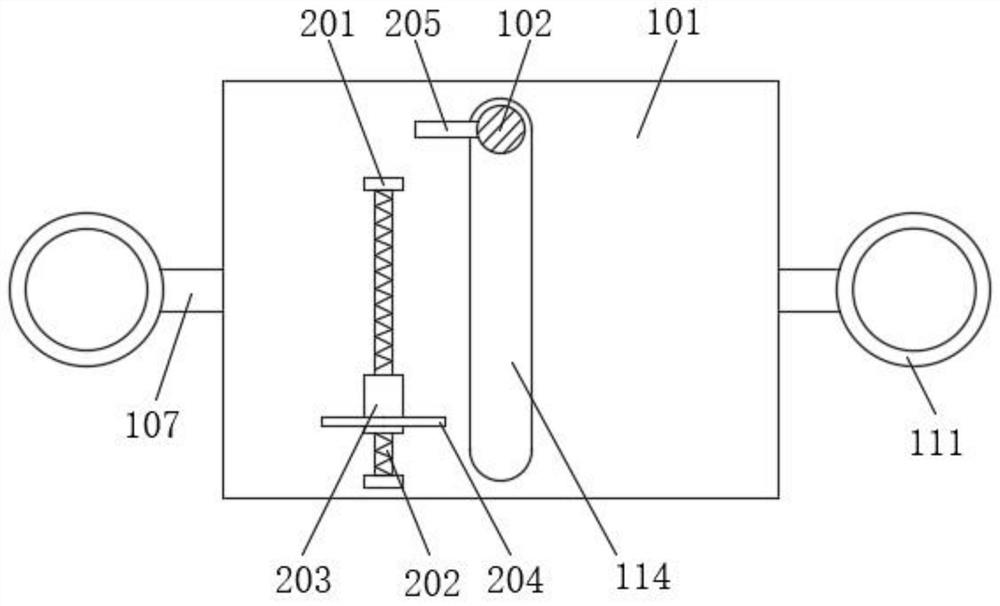

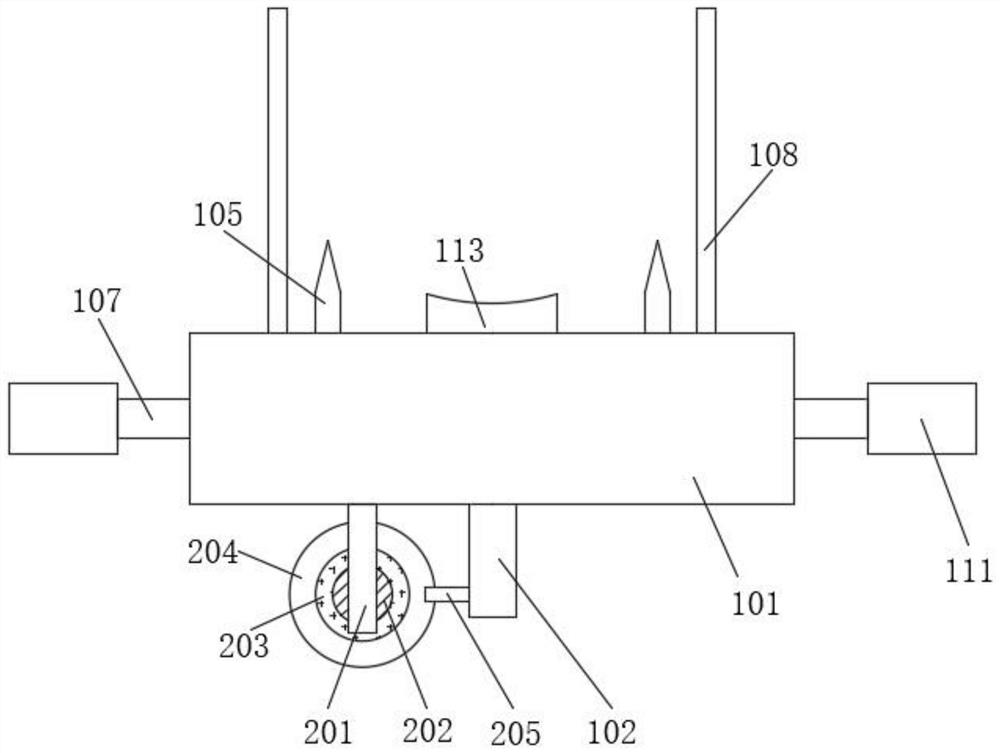

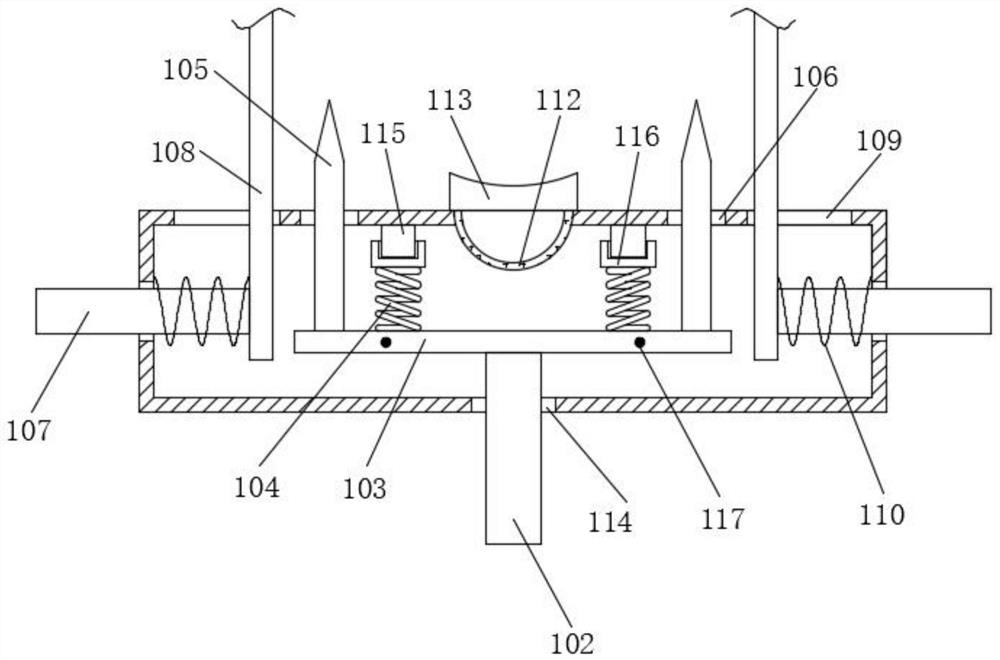

[0043] see Figure 1-6 , a kind of improved mulberry tree budding technology based on sheet budding method, comprises the following steps:

[0044] S1, select the kind that grows vigorously and has no seedlings of diseases and insect pests or eliminates as rootstock;

[0045] S2, fixing the skinning auxiliary device to the rootstock selected in S1, and cutting two parallel vertical tangent lines on the rootstock through the skinning auxiliary device;

[0046] S3, using a blade, cut horizontally from the top and the bottom of a stock vertical tangent line to the top and the bottom of another root stock vertical tangent line, cut two parallel root stock cross-cutting lines, and take off the bark of the stock stock removed, thereby forming an interface on the rootstock;

[0047] S4, choose a branch with full leaf buds from a mulberry tree that is robust, high yield, and free of diseases and insect pests, and the thickness of the branch is roughly similar to that of the rootstoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com