Municipal trimming and irrigation equipment for green forest shrubs along roads

A technology for roads and green forests, which is applied to the field of pruning and irrigation equipment for green forests and shrubs along municipal roads, can solve the problems of affecting the appearance and low efficiency of shrub work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

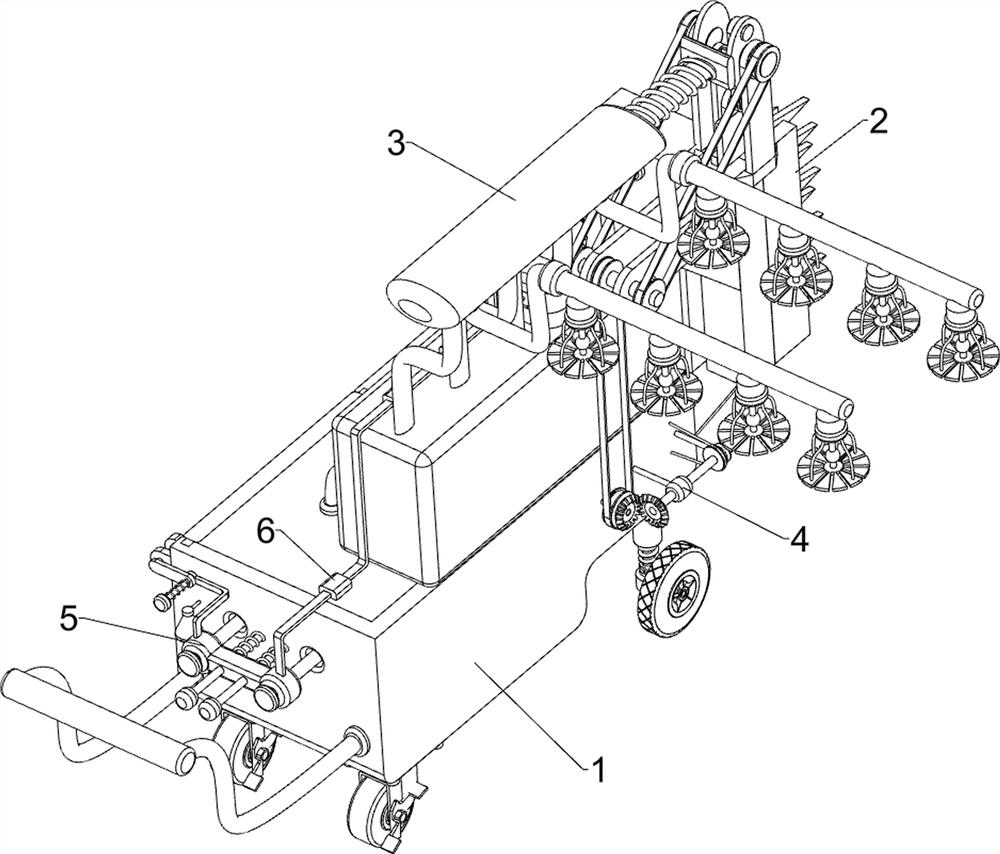

[0047] A kind of irrigation equipment for trimming and trimming green forest shrubs along the side of municipal roads, such as Figure 1 to Figure 3 As shown, it includes a moving mechanism 1 and a trimming mechanism 2, which is provided with a moving mechanism 1, and the right side of the top of the moving mechanism 1 is provided with a trimming mechanism 2.

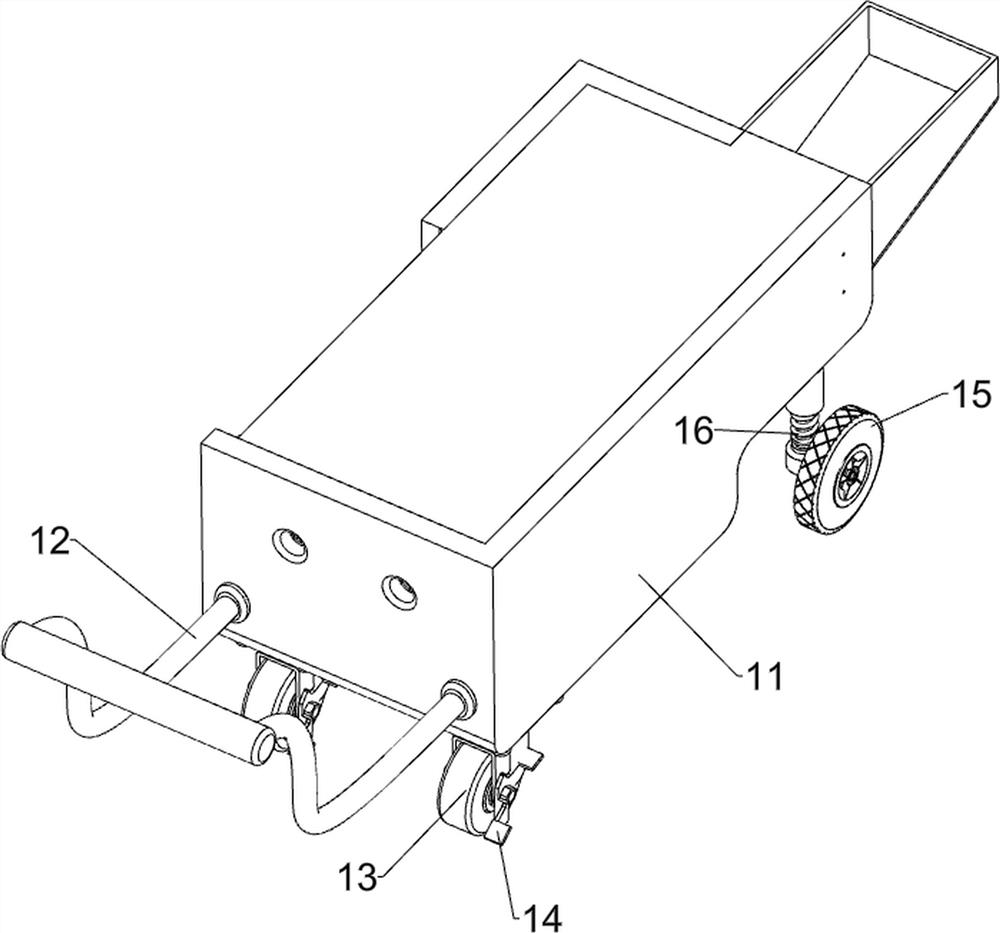

[0048] Mobile mechanism 1 comprises collection frame 11, push handle 12, rear wheel 13, brake 14, front wheel 15 and first spring 16, and it is provided with collection frame 11, and collection frame 11 bottom left side is symmetrically provided with rear wheel 13, and rear wheel 13 outer sides are equipped with brakes 14, and the right side of the collection frame 11 is symmetrically sliding with front wheels 15. The first spring 16 is connected between the front wheels 15 and the bottom of the collection frame 11, and the left side of the collection frame 11 is connected with a push handle. 12.

[0049] The trimming ...

Embodiment 2

[0052] On the basis of Example 1, such as Figure 4 and Figure 5 As shown, watering mechanism 3 is also included, and watering mechanism 3 includes pumping bucket 31, depression bar 32, second spring 33, water pipe 34, shower nozzle 35, support rod 36 and water tank 37, and collecting rack 11 top front side is provided with There are 2 groups of support rods 36, and a water tank 37 is connected between the tops of the support rods 36, and a water tank 31 is connected to the top of the water tank 37, and the right side of the water tank 31 is slidingly provided with a depression bar 32, between the pressure rod 32 and the left side of the water tank 31. A second spring 33 is connected between them, and water pipes 34 are symmetrically connected to the front side of the bottom of the water bucket 31, and four nozzles 35 are connected to the bottom of the water pipes 34.

[0053]The rotation of the blade 25 drives the cam to rotate. When the cam rotates to contact with the pres...

Embodiment 3

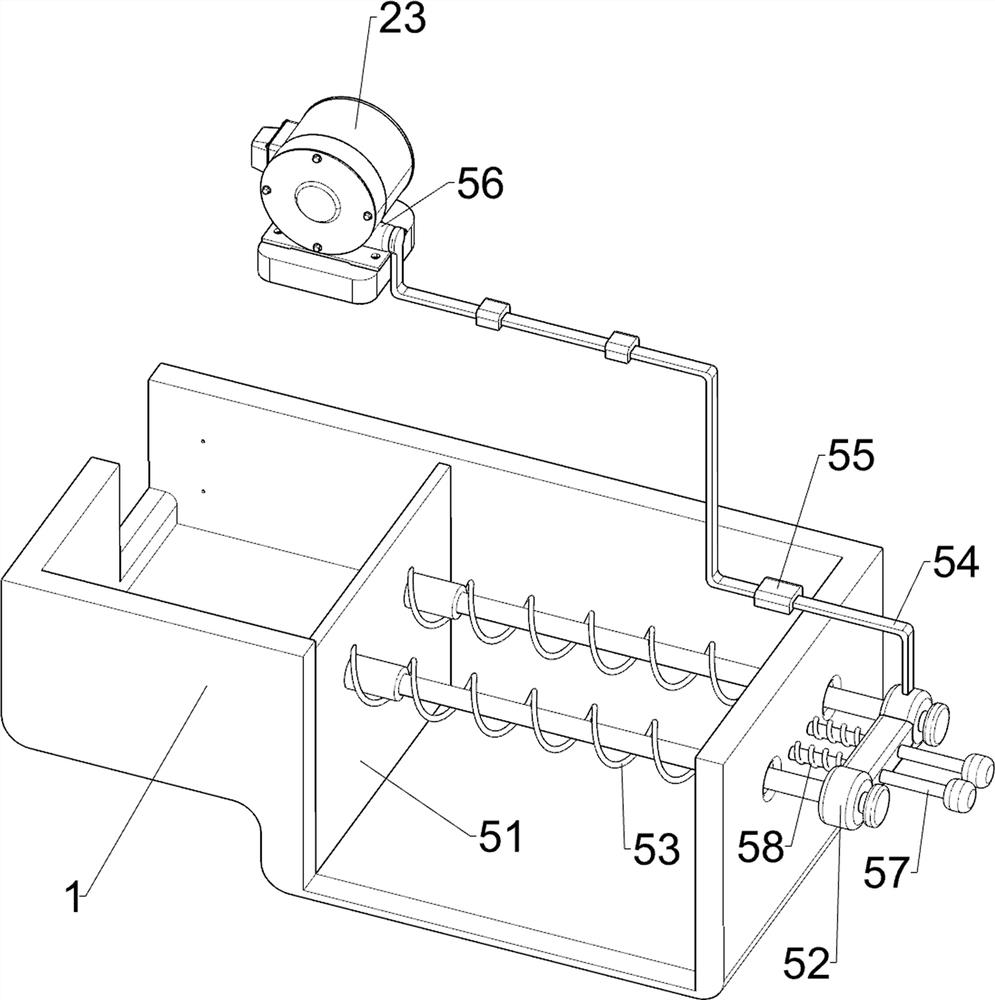

[0057] On the basis of Example 2, such as Figure 6 and Figure 7 As shown, a switch mechanism 5 is also included, and the switch mechanism 5 includes a second baffle plate 51, a push rod 52, a third spring 53, a touch lever 54, a fixed block 55, a button 56, a third fixed rod 57 and a fourth The spring 58 is slidably connected with a second baffle plate 51 between the inner walls of the collection frame 11, and a push rod 52 is connected between the left side of the second baffle plate 51 and the collection frame 11, and the push rod 52 is sleeved with a third spring 53. The third spring 53 is connected between the second baffle plate 51 and the collection frame 11, and the left part of the push rod 52 is connected with a touch lever 54, and several fixed blocks 55 are connected on the top of the collection frame 11 and the top of the water tank 37. Slidably connected with the touch lever 54, the left side of the motor 23 is provided with a button 56, the button 56 cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com