Precision filter and air compressor with same

A precision filter and air compressor technology, applied in the field of air compressors, can solve the problems of affecting the sealing effect of the filter, complex use environment of the air compressor, inconvenient operation, etc., and achieve the effects of convenient cleaning, maintenance and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

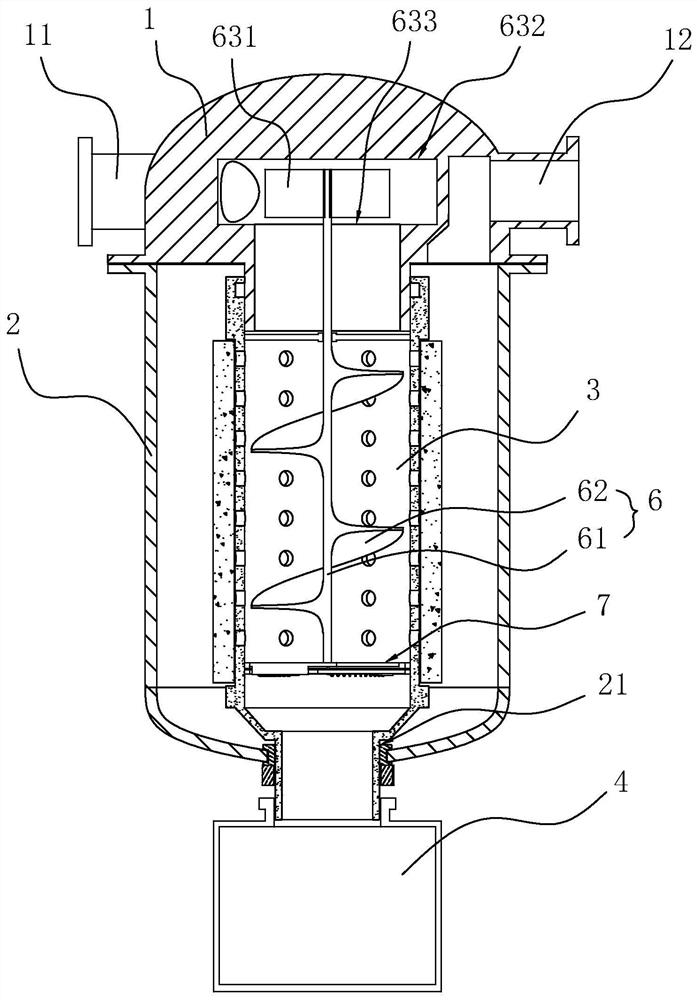

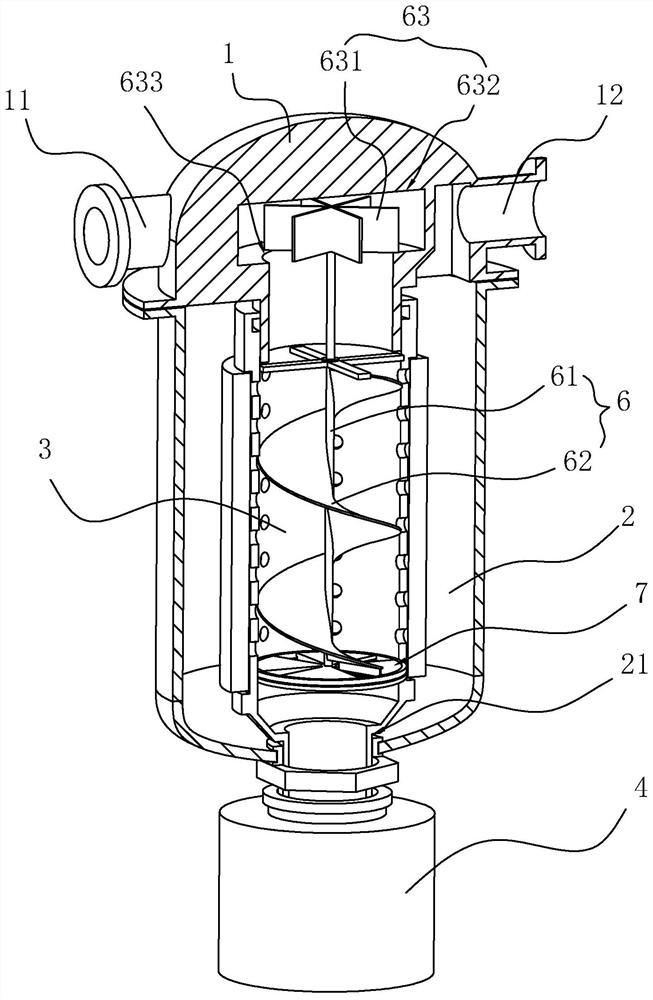

[0037] The following is attached Figure 1-8 The application is described in further detail.

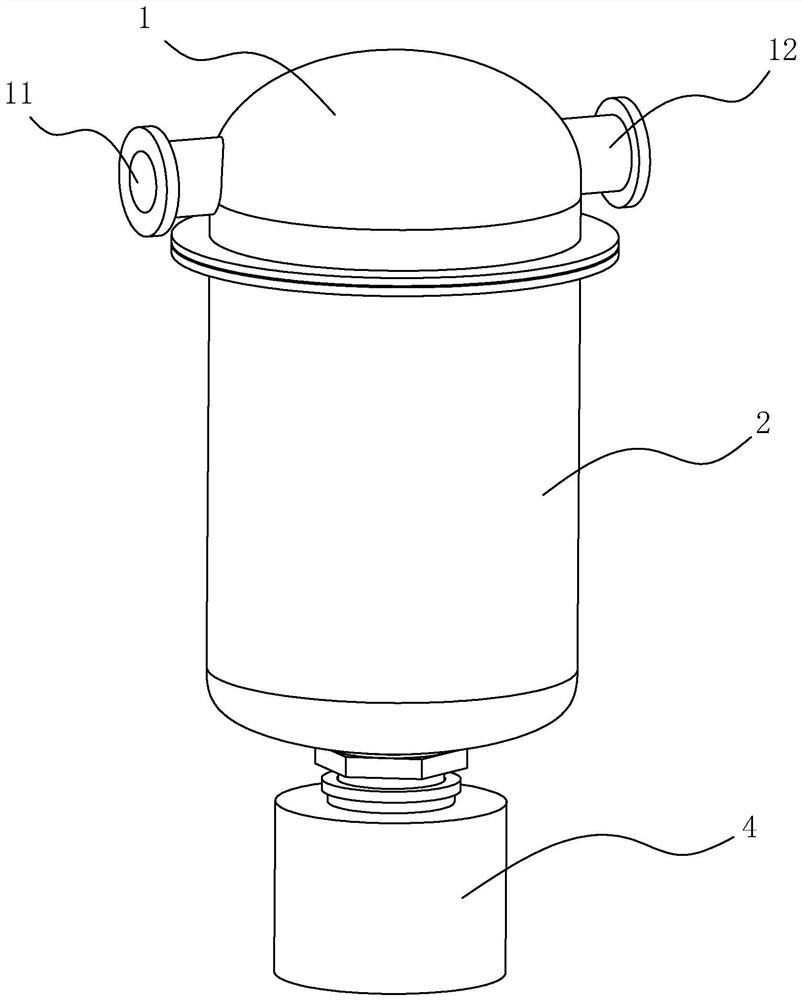

[0038] The embodiment of the present application discloses a precision filter. refer to figure 1 , 2, The filter includes a top shell 1, a bottom shell 2, a filter element 3 and a collection cylinder 4. The inside of the bottom case 2 is hollow and the top is open. The top case 1 and the top of the bottom case 2 are connected by flange bolts. The outer wall of the top case 1 is provided with an air inlet 11 and an air outlet 12. The other ends are connected to the bottom case 2 . The filter element 3 is installed in the bottom shell 2. The filter element 3 includes a core cylinder and a filter layer. The filter layer is composed of HEPA filter screen, filter paper and activated carbon layer in sequence. The core cylinder is hollow inside and has openings at both ends. There are The vent hole communicated with the inside of the core tube, and the filter layer is sleeved on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com