Waste gas treatment device for biological fermentation tank

A technology of waste gas treatment device and biological fermentation tank, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., and can solve the problems of complex operation and poor treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

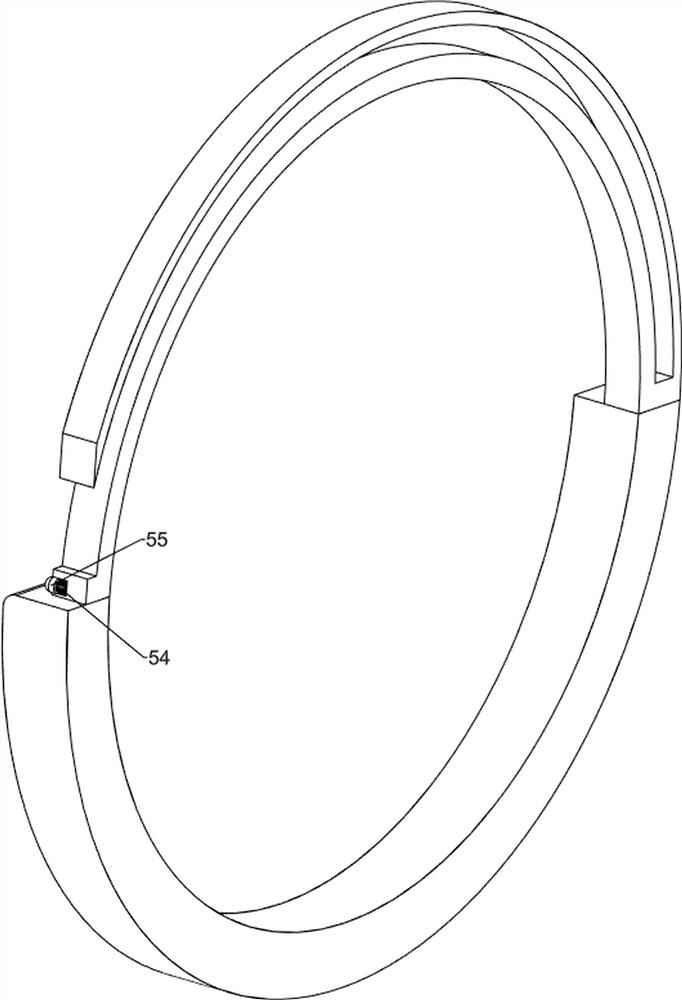

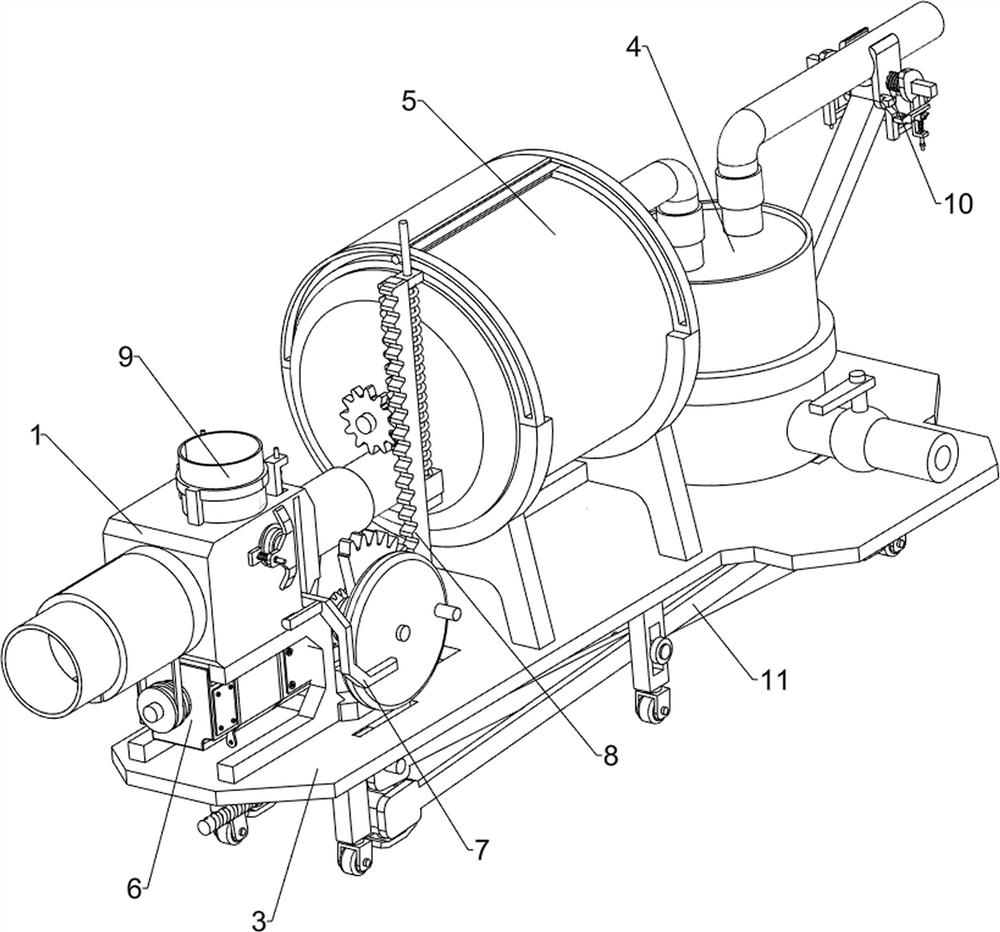

[0094]A biological fermenter exhaust gas treatment device, such asfigure 1 withfigure 2 As shown, there is an air tube 1, a dust plate 2, a bottom plate 3, a disinfection mechanism 4, and a filter mechanism 5, and the upper side of the bottom plate 3 is connected to the air pipe 1, the inner wall of the air pipe 1 is connected to the upper side of the bottom plate 3. The disinfecting mechanism 4 is connected, and the filter mechanism 5 is connected to the upper side of the bottom plate 3.

[0095]When the device needs to be used, the user can pour the disinfection water into the disinfection mechanism 4, pull up the filter mechanism 5 up, put the activated carbon into the filter mechanism 5, pull the filter mechanism 5 down, and put the exhaust gas input disinfection mechanism 4, The exhaust gas is disinfected by the disinfection mechanism 4 to achieve a purpose of disinfection of exhaust gas, and the exhaust gas enters the filter mechanism 5, the exhaust gas is subjected to secondary ...

Embodiment 2

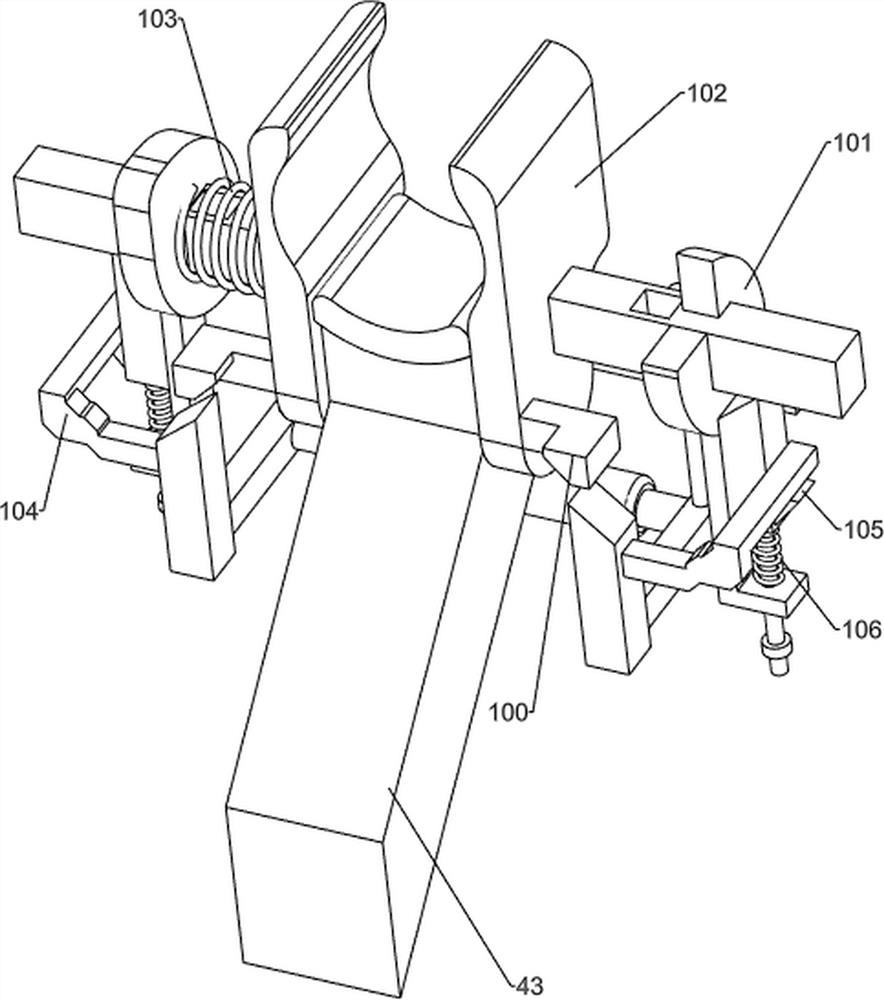

[0097]On the basis of Example 1, such asimage 3 As shown, the disinfection mechanism 4 includes a sterilizing tub 40, an intake pipe 41, a spherical valve 42, and a first support block 43, and the upper side of the bottom plate 3 is connected to the first support block 43, and the inner side of the first support block 43 is connected to the disinfecting bucket 40, On the upper side of the sterilizer 40 is connected to the air pipe 41, the spherical valve 42 is connected to the right side of the sterilizer 40, and the spherical valve 42 passes through the sterilizing bucket 40.

[0098]When the device needs to be used, the user can pour the disinfection water into the disinfection tub 40, pull the filter mechanism 5 up, and place the activated carbon into the filter mechanism 5, pull the filter mechanism 5 downward, and pull the exhaust gas into the trachea 41. The exhaust gas enters the disinfection barrel 40 through the intake pipe 41, and the exhaust gas is disinfected once by disinf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com