Track coating device and process method

A track and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of artificial brushing and flow, uneven thickness of the protective agent, easy splashing and dripping, etc., to improve the quality, Increased productivity and reduced labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

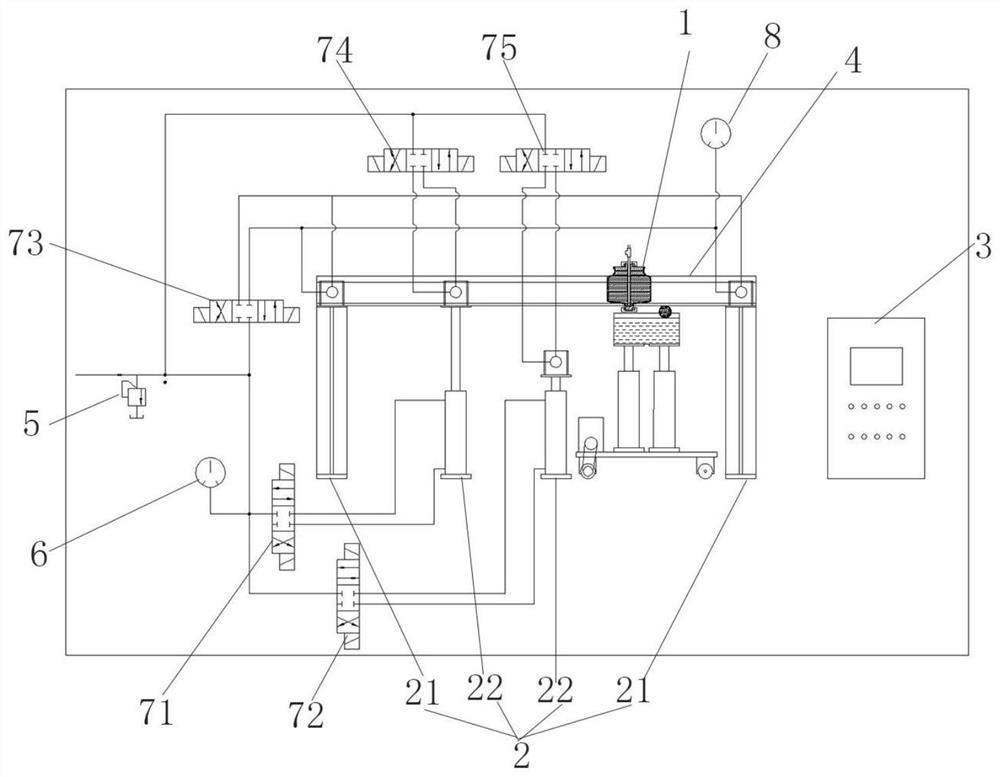

[0041] A device for rail coating such as figure 1 As shown, it includes a profiled roller coating device 1 for automatic roll coating on the track, a support device 2 and a control system 3 for supporting the track, the profile of the profiled roller of the profiled roll coating device 1 and the profile of the rail 4 Matched, the control system 3 is electrically coupled with the forming roller coating device 1 and the supporting device 2 .

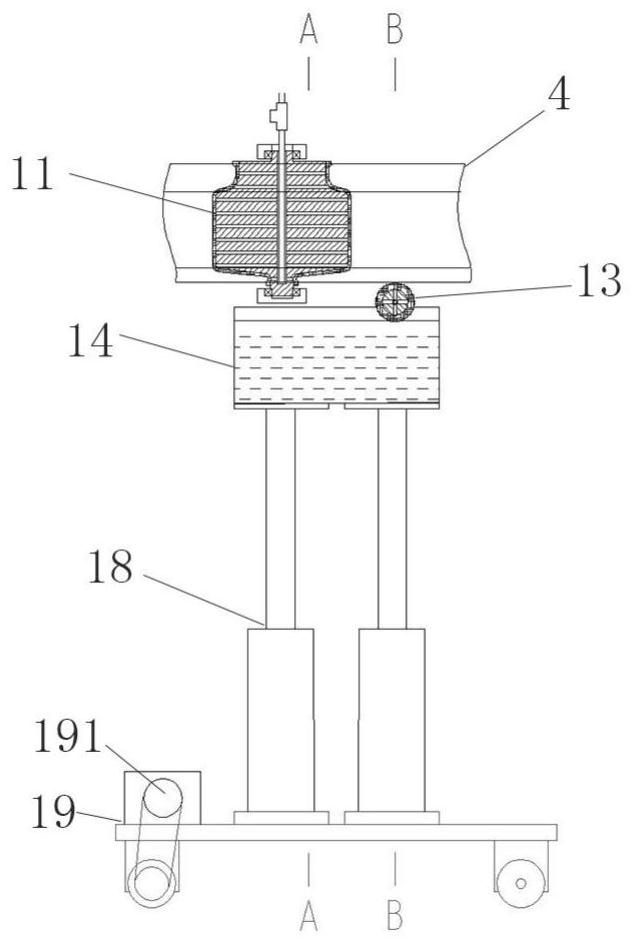

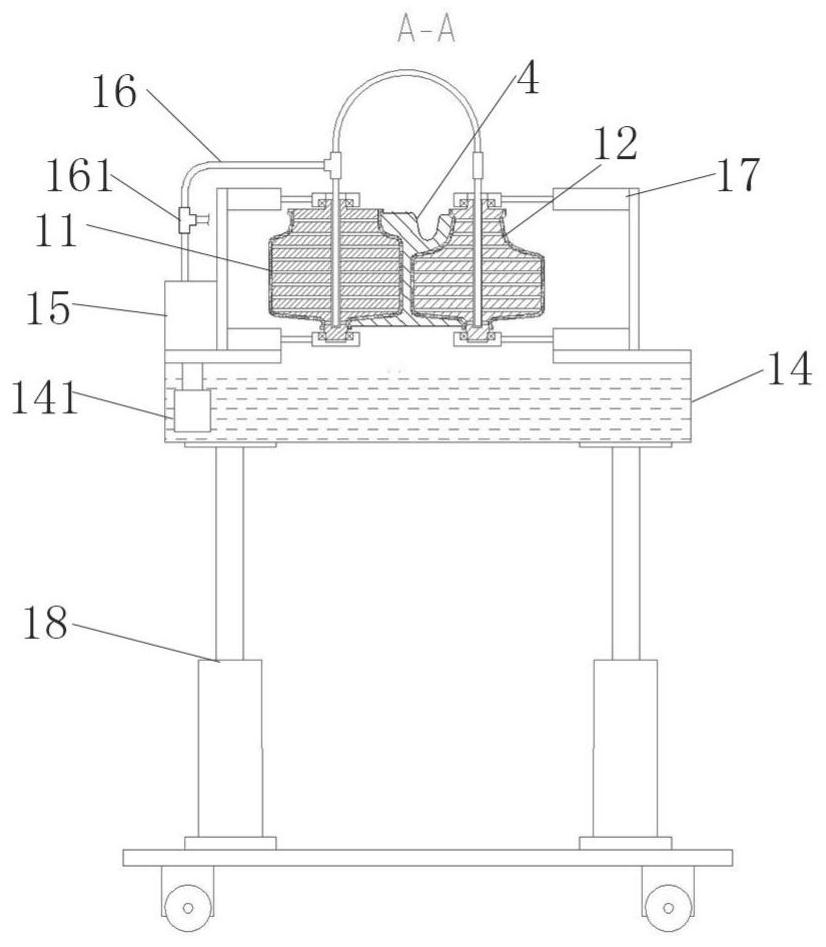

[0042] Specifically, such as Figure 2-4 As shown, the forming roller coating device 1 is composed of a forming roller device, a feeding device and a driving device.

[0043] More specifically, the forming roll device includes a first side roll device 11 , a second side roll device 12 and a bottom roll device 13 . The first side roll device 11, the second side roll device 12 and the bottom roll device 13 comprise forming rolls, and the outer layer of the forming roll is provided with a coating layer 103, and the first side roll device 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com