Dispensing device for electronic transformer production and based on limiting extrusion mechanism

A technology of electronic transformer and extrusion mechanism, which is applied to the surface coating liquid device, spray device, coating, etc., which can solve the problems affecting the accuracy of dispensing, difficult to control glue, and low production efficiency, and reach the control point The amount of glue, the effect of saving resources and improving the quality of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

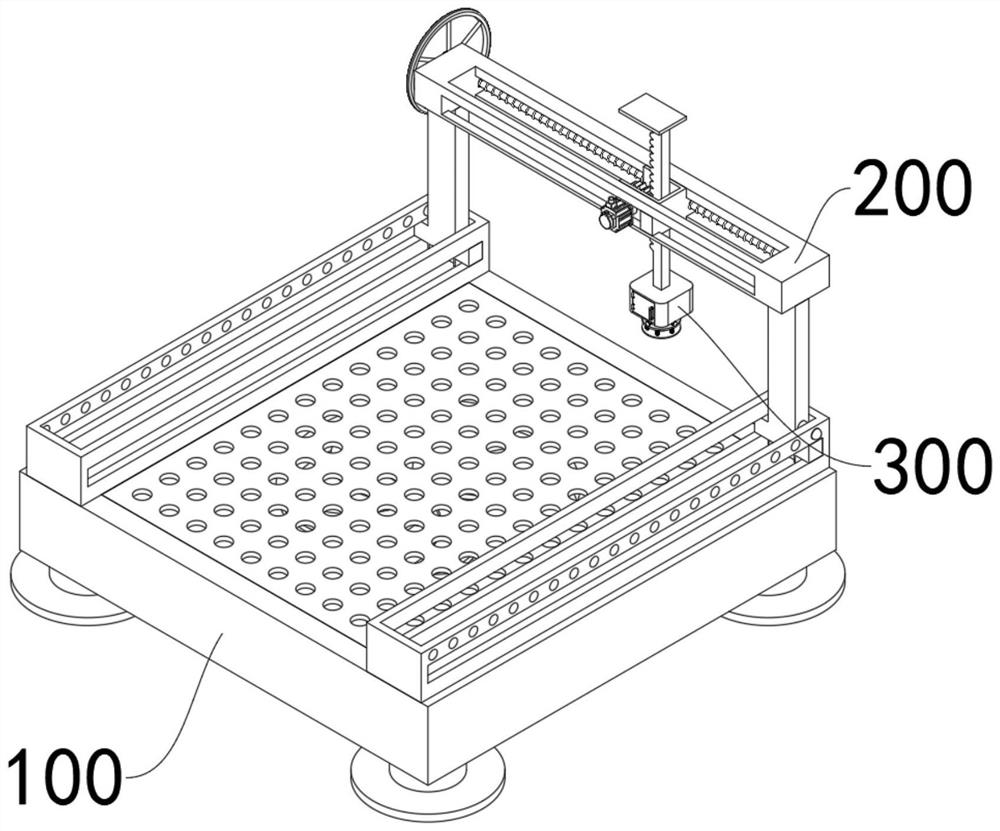

[0041] see Figure 1-Figure 10 As shown, this embodiment provides a dispensing device for electronic transformer production based on a limit extrusion mechanism, at least including:

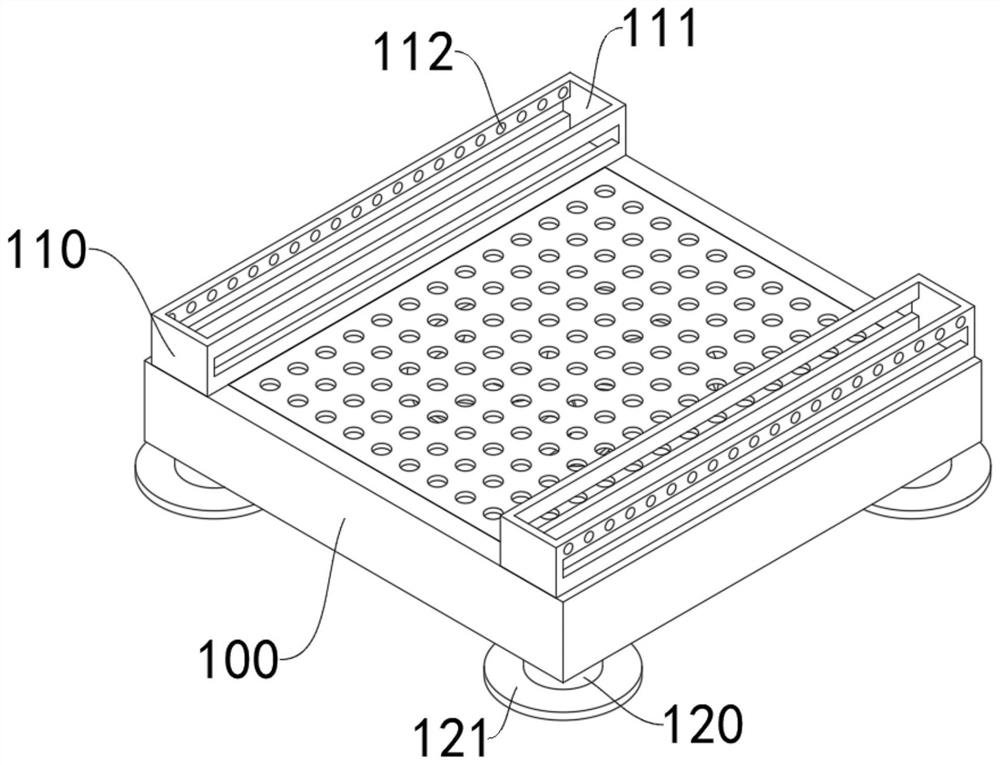

[0042] The support plate 100, two symmetrical longitudinal adjustment blocks 110 are arranged on the top of the support plate 100 close to the edge, and the top of the longitudinal adjustment block 110 is provided with a chute 111;

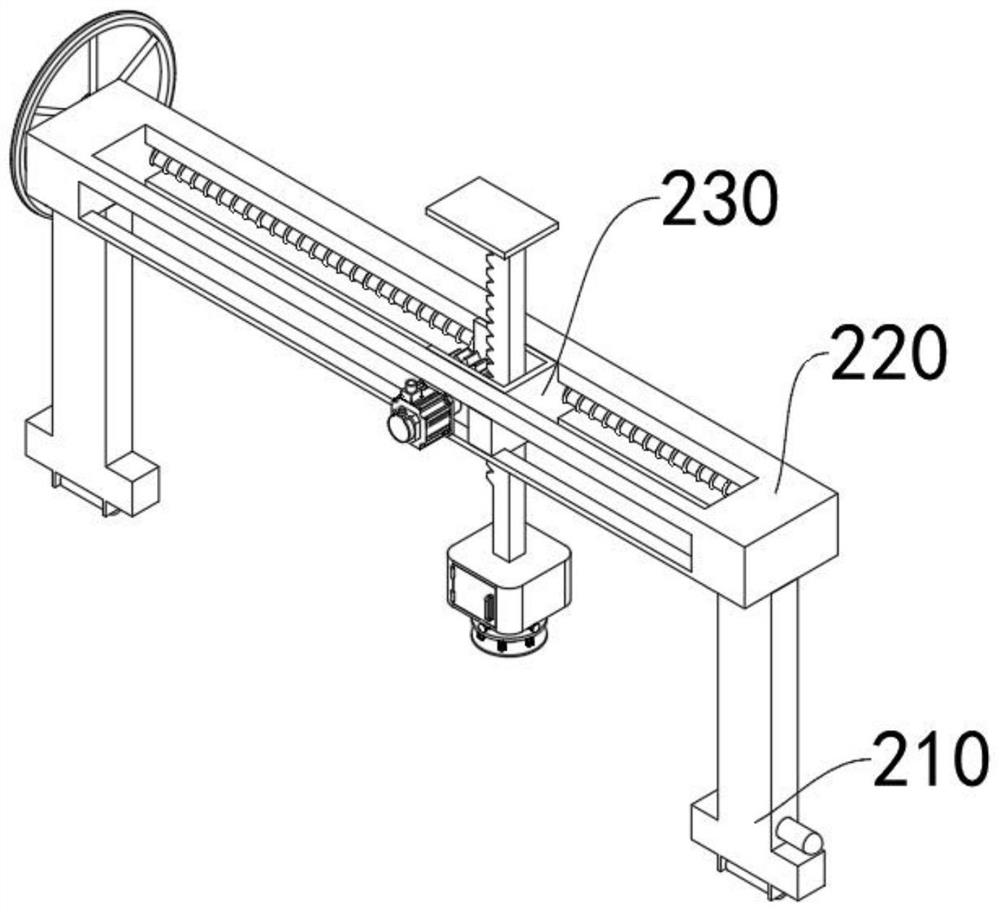

[0043]The adjustment mechanism 200, the adjustment mechanism 200 includes two symmetrical sliders 210, the sliders 210 slide inside the chute 111, push the slider 210, the slider 210 can slide left and right inside the chute 111, the top of the two sliders 210 A horizontal adjustment frame 220 is fixedly connected between them, and an adjustment groove 221 is provided on the top of the horizontal adjustment frame 220. A transmission frame 230 is slid inside the adjustment groove 221, and a linkage gear 232 is installed on the inside of the transmission frame 230, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com