Strip steel control plate type operation method

An operation method and control board technology, applied in the direction of contour control, etc., can solve the problems of large inclination of the mid-tail, floating finish rolling, difficult control, etc., and achieve the effects of low set, reduced tail drift, and good plate shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

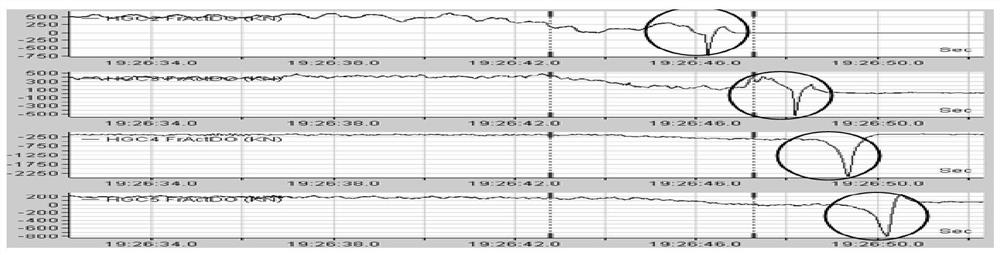

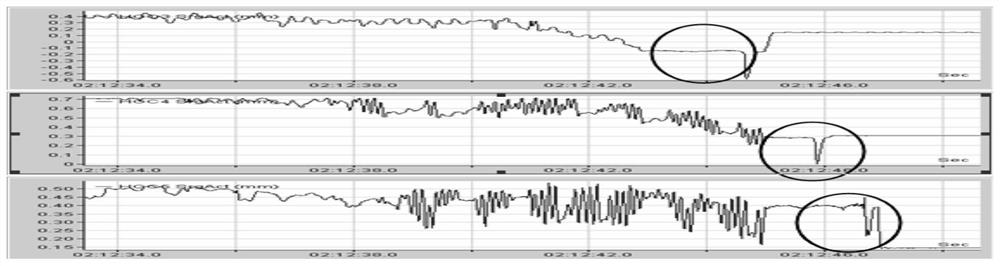

[0054] according to Figure 1-2 As shown, the strip steel shape control method of the present invention is compared with the traditional strip steel shape control operation method. From the rolling force deviation diagram, we can clearly see that the adjustment range is reduced after canceling the AGC.

[0055] After using the strip steel shape control operation method of the present invention, the overall shape of the strip steel is effectively controlled, quality objections and roll consumption are reduced, the quality of the workshop is guaranteed, and the production cost is also reduced for the enterprise , It has laid a solid foundation for enhancing the corporate image and enhancing market competitiveness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com