Electronic connector detection and discharging device and method

A technology of electronic connectors and detection mechanisms, applied in the directions of transportation and packaging, conveyor objects, sorting, etc., can solve the problem of increasing the cost of equipment cylinders, reducing friction, reducing the accuracy of rubber core positioning fixtures to receive rubber cores, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

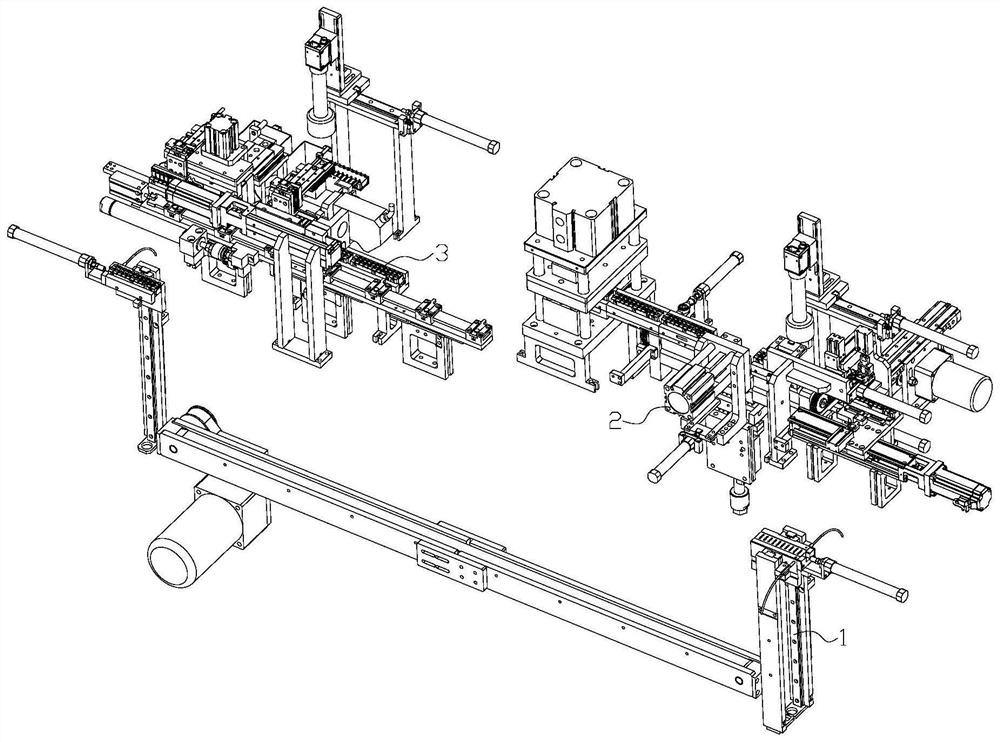

[0038] Such as figure 1 An electronic connector assembly equipment is shown, which includes a workbench and a jig circulation device 1 fixed on the workbench, a feeding riveting device 2 and a detection and unloading device 3; both ends of the jig circulation device 1 are respectively connected to The input end of the feeding riveting device 2 is connected with the output end of the detection and blanking device 3; the output end of the feeding riveting device 2 is connected with the input end of the detection and blanking device 3; the jig circulation device 1 is used for the circulation of the rubber core positioning jig Conveying; the feeding and riveting device 2 is used for feeding the rubber core and pins and the riveting between the two; the detecting and unloading device 3 is used for detecting and unloading the assembled electronic connector.

[0039] The product flow direction of the electronic connector is: jig circulation device 1 to feeding riveting device 2 to de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com