Melt-blown fabric segmented cutting machine for mask production

A technology of melt-blown cloth and cutting machine, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., and can solve the problem of inaccurate cutting length and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

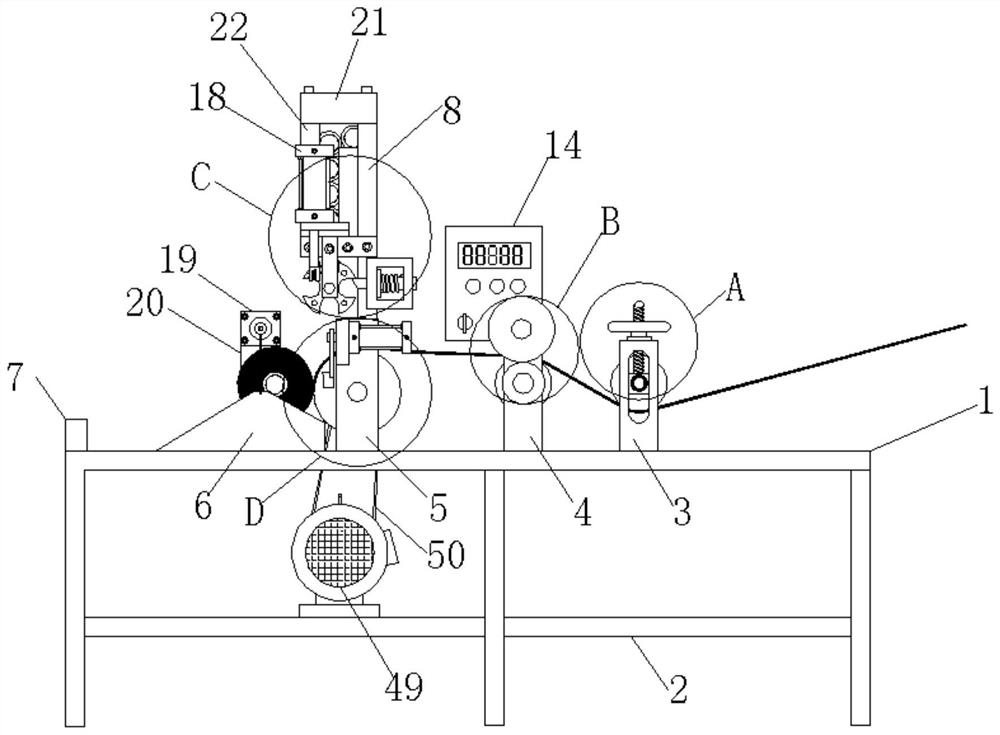

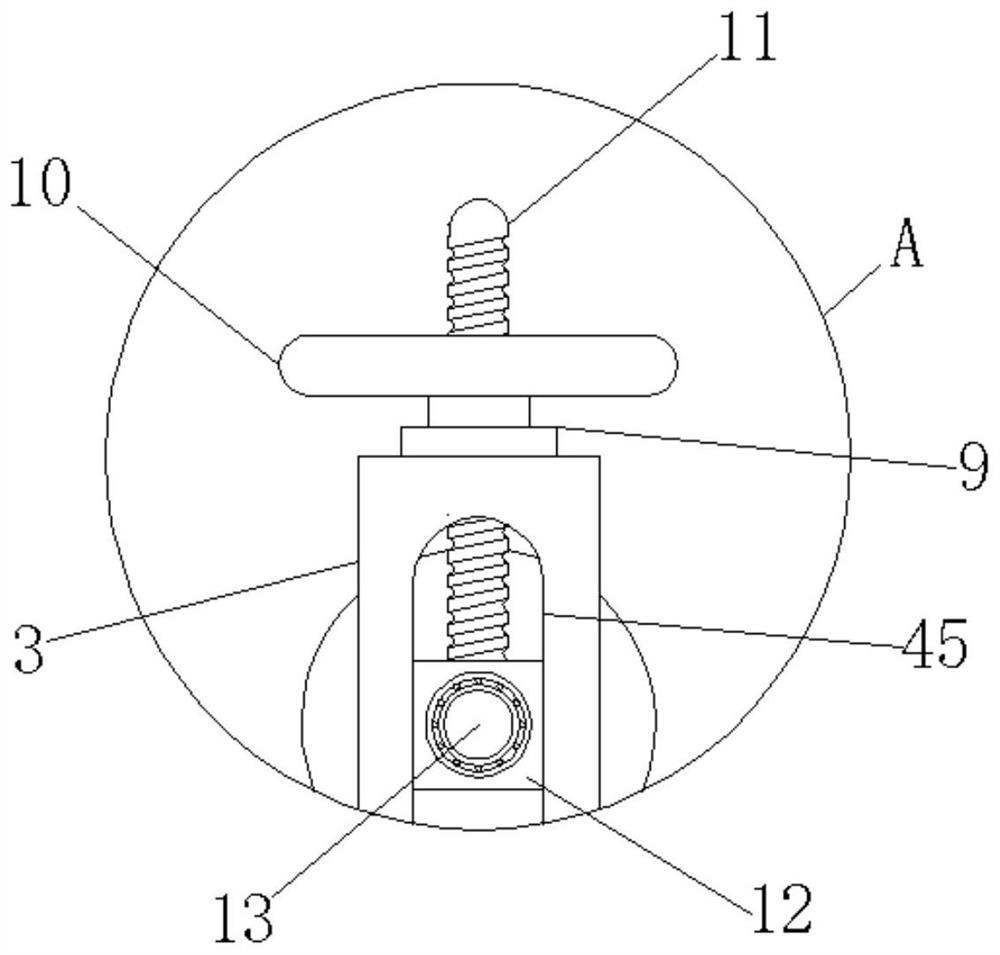

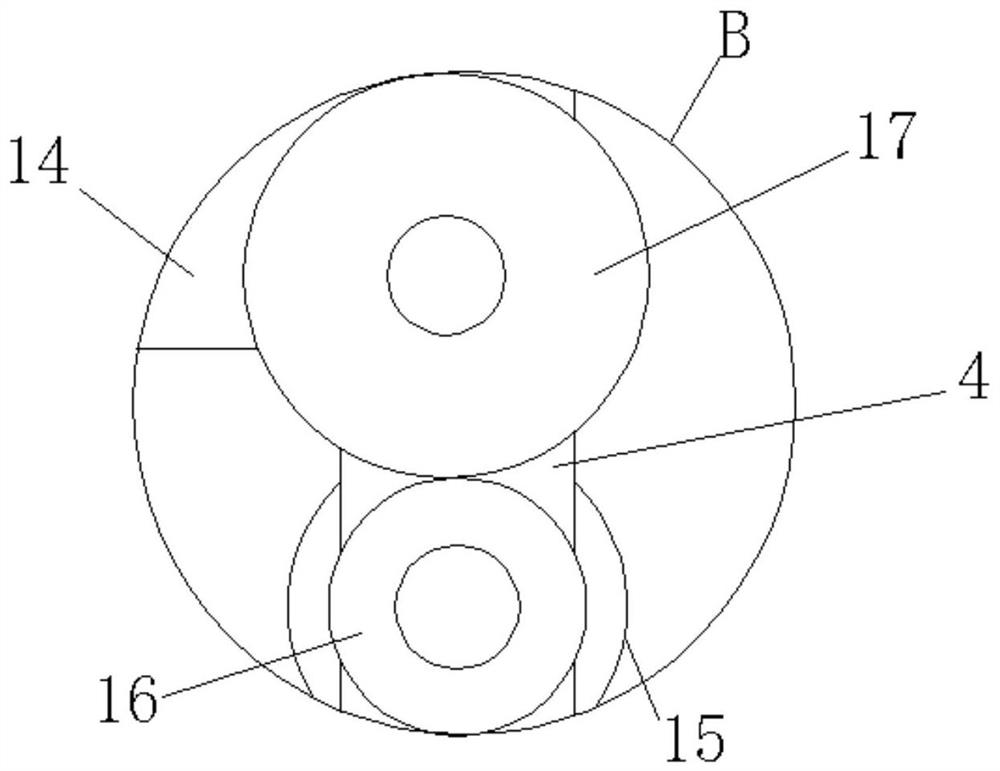

[0039] like Figure 1-13 As shown, the embodiment of the present invention provides a segmental cutting machine for melt-blown cloth for mask production, including a frame 1, the inner side of the frame 1 is fixedly connected with a lower beam 2, and the upper surface of the lower beam 2 is fixedly connected with a motor 49, and the frame 1. The upper surface is fixedly connected with the first support 3, the second support 4, the third support 5, the support frame 6, and the stopper frame 7 in order from right to left. The rear wall of the frame 1 is fixedly connected with the fifth support 20. The inner wall of a support 3 is rotatably connected with a tensioning wheel 13, the inner side of the first support 3 is provided with a tensioning adjustment device, the inner wall of the second support 4 is rotatably connected with a supporting wheel 15, and the upper surface of the second support 4 is fixedly connected with a meter counting device. The inner wall of the third suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com