Coiling frame for earcap rope

A technology of earmuffs and winding wires, which is applied in the field of earmuff rope production, can solve the problems of easy formation of high piles and the inability to fill the inner cavity of the packing box, so as to achieve the effect of improving elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

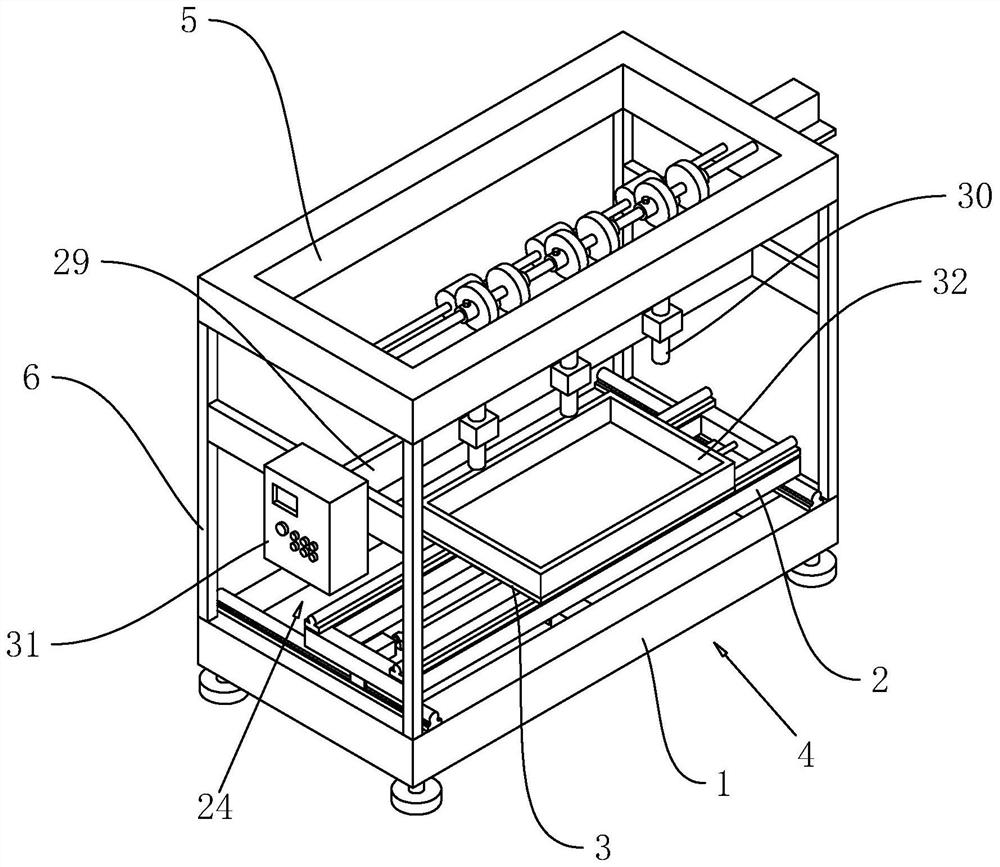

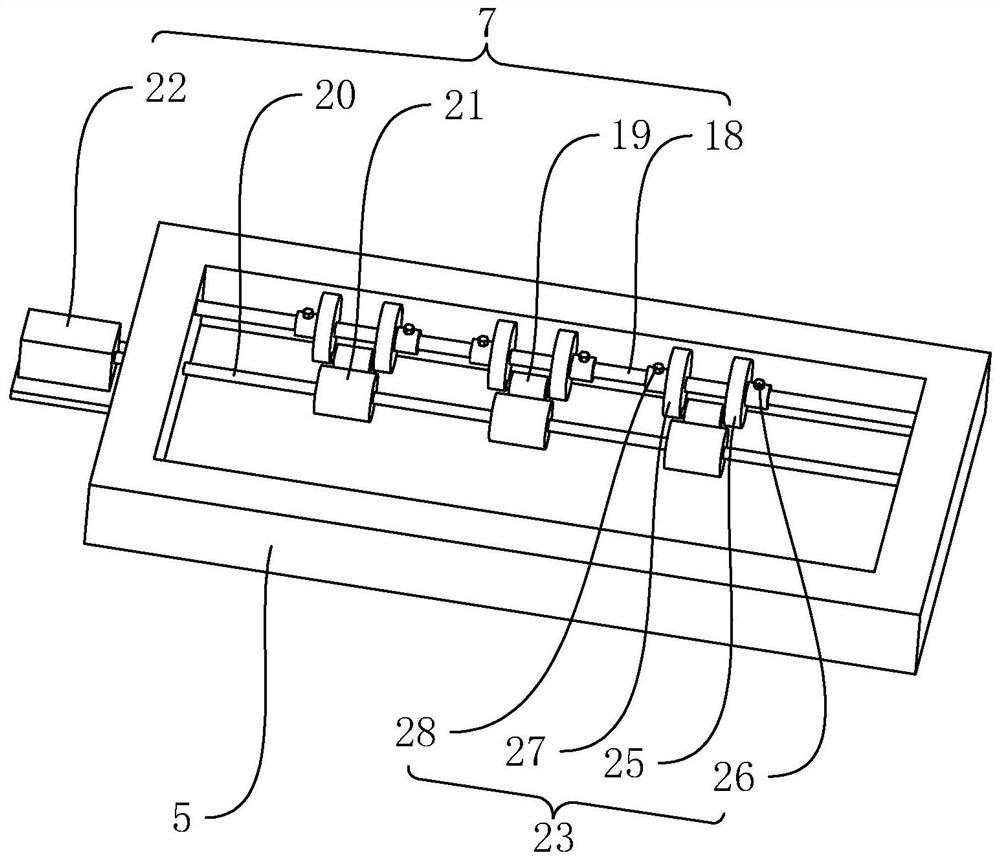

[0031] Embodiment 1, the first aspect The embodiment of the present application discloses a coiling frame for ear loop cords.

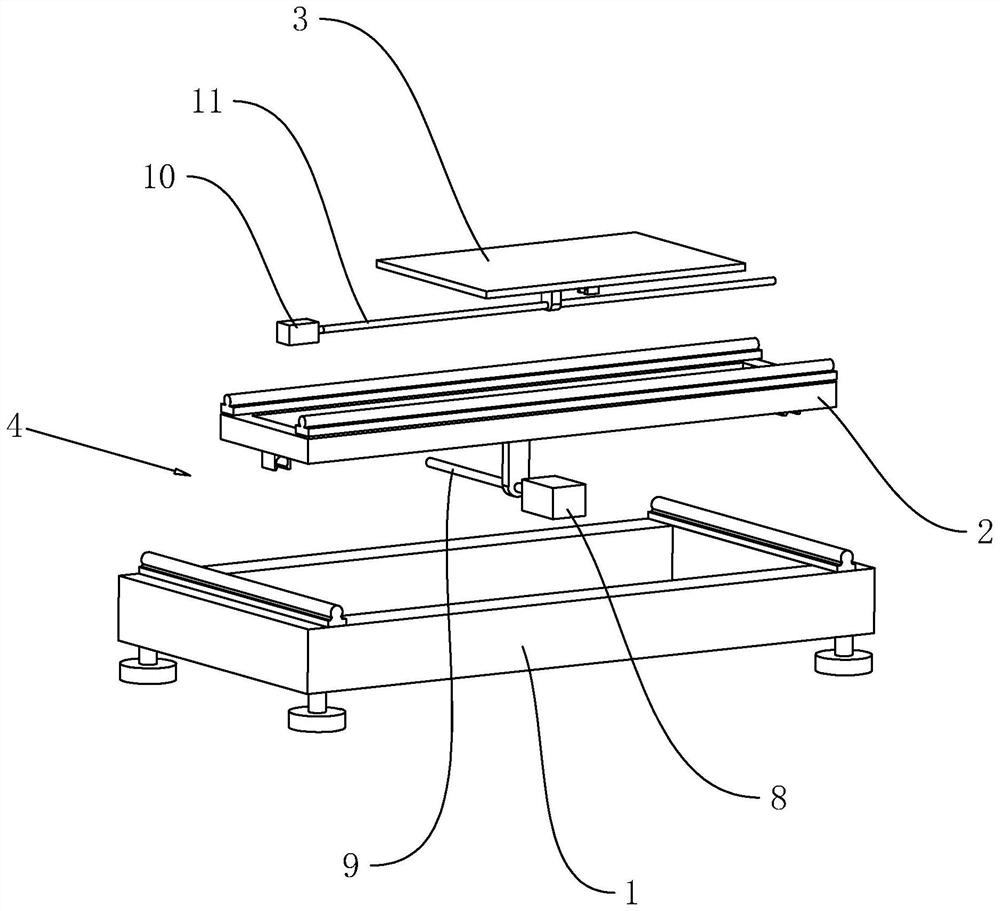

[0032] refer to figure 1 , a coil frame for ear loop ropes, comprising a bottom frame 1, the bottom frame 1 is a rectangular frame, the bottom frame 1 is placed on the ground through feet, an installation frame 2 is arranged on the upper surface of the bottom frame 1, the installation frame 2 Slide along the width direction of the bottom frame 1, the upper surface of the installation frame 2 is provided with a placement plate 3, the placement plate 3 slides along the length direction of the bottom frame 1, the sliding direction of the placement plate 3 is the same as that of the installation frame 2 The sliding direction is set vertically, so that the packing carton used to accommodate the ear loop rope is placed on the upper surface of the placing board 3, and both the placing board 3 and the packing carton can slide along the length direction of the...

Embodiment 2

[0040] Embodiment 2, the second aspect The embodiment of the present application discloses a winding frame for earloop cords.

[0041] refer to Figure 4 The difference between the second embodiment and the first embodiment is that the drive assembly 4 includes a third servo motor 12, a third reciprocating lead screw 13 and is arranged on the bottom frame 1 for driving the placement plate 3 along the installation frame 2. The connecting assembly 14 reciprocatingly slides in the length direction, the third servo motor 12 is fixed on the bottom surface of the bottom frame 1, the third reciprocating screw 13 is rotatably connected to the bottom surface of the bottom frame 1, and the third reciprocating screw 13 is coaxially fixed on the bottom surface of the bottom frame 1. On the rotating shaft of the third servo motor 12 , the mounting frame 2 is screwed to the third reciprocating lead screw 13 .

[0042] refer to Figure 4 , the connection assembly 14 includes a rack 15, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com