Warp knitting machine for textile based on fluff absorption mechanism

An absorption mechanism and warp knitting machine technology, applied in the field of warp knitting machines, can solve the problems of inaccurate needle displacement, dispersion of flying flocs, high labor intensity, etc., and achieve the effects of increasing use time, saving driving resources, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

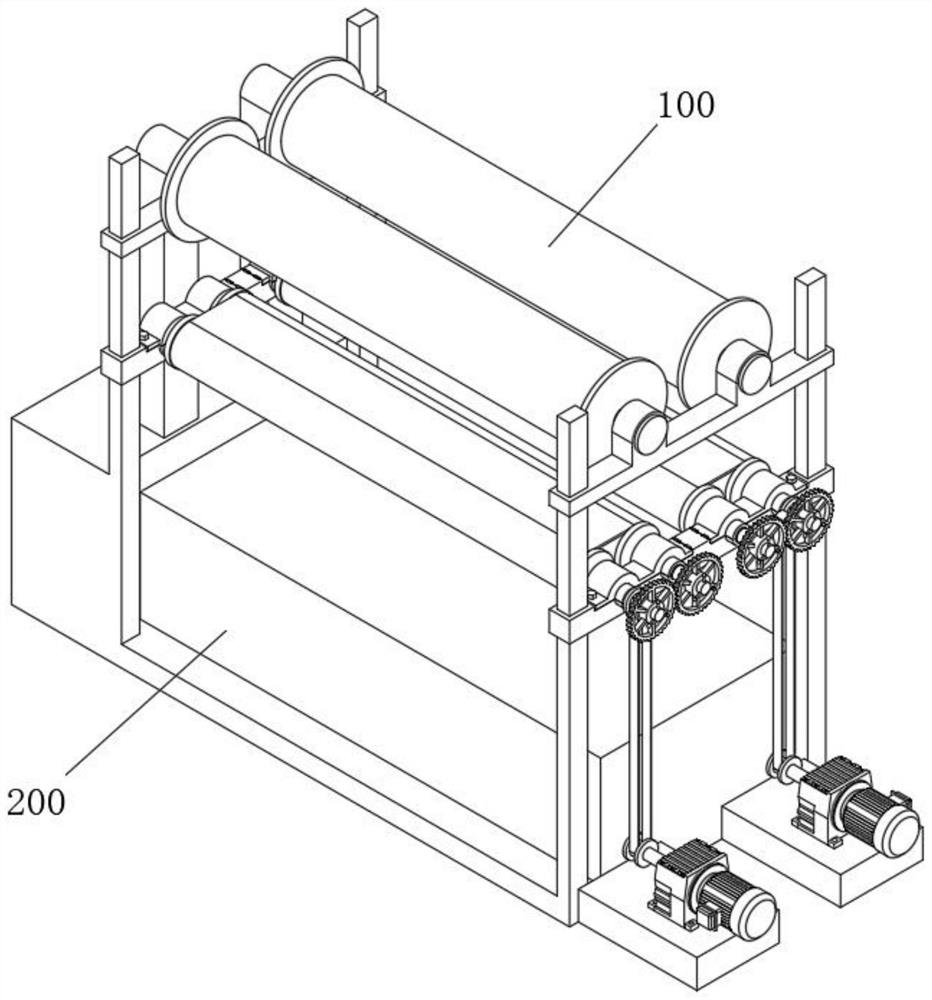

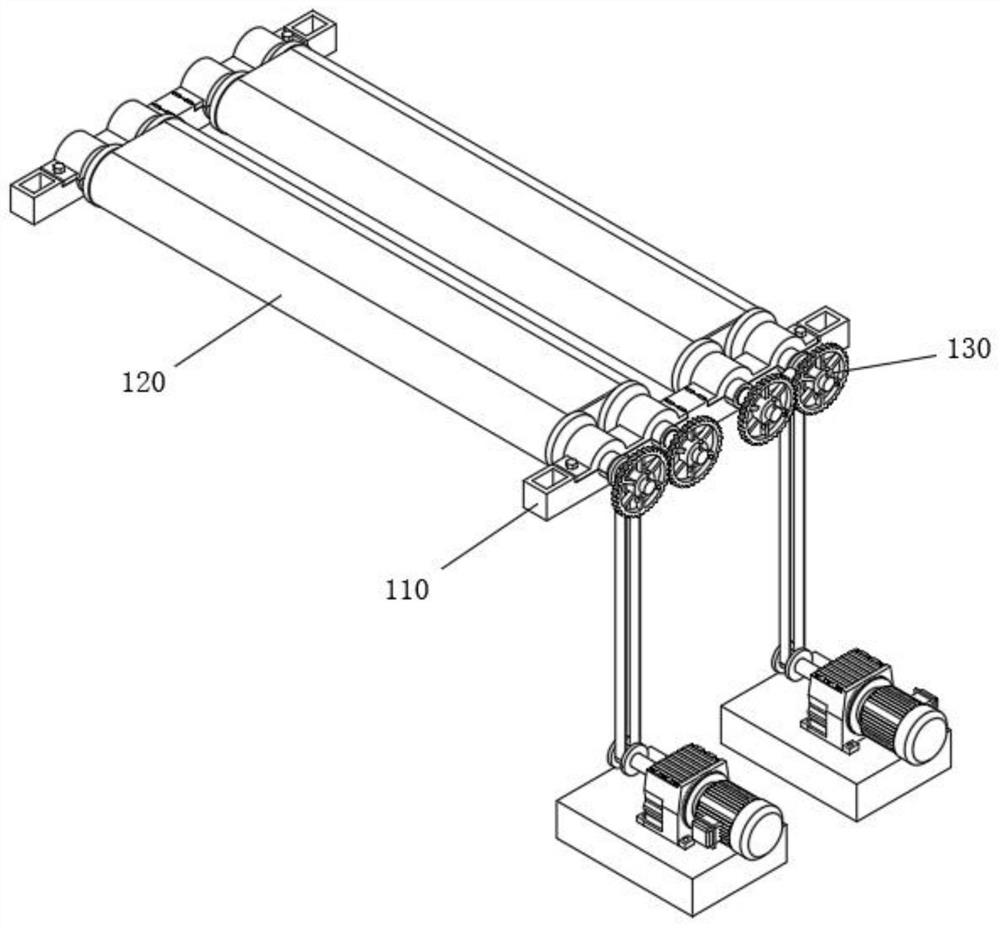

[0054] see Figure 1-Figure 12 As shown, this embodiment provides a warp knitting machine for weaving based on a batt absorption mechanism, including a warp knitting machine body 200 and a wool absorption mechanism 100 installed inside the warp knitting machine body 200. The wool absorption mechanism 100 at least includes:

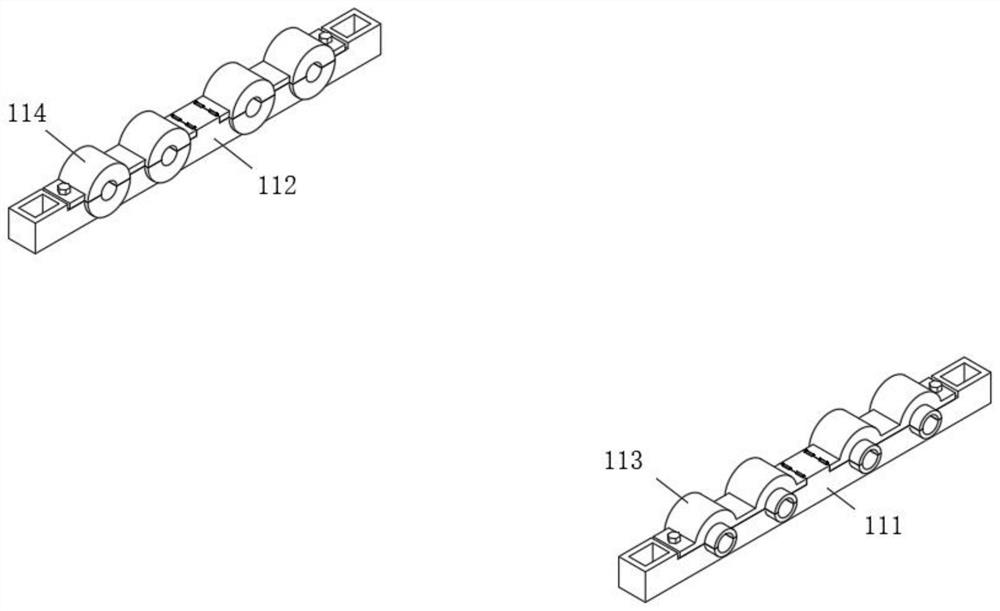

[0055] The support frame 110 includes a right support frame 111 and a left support frame 112 located on the left side of the right support frame 111. The right support frame 111 and the left support frame 112 are symmetrically provided with two, and the upper surface of the right support frame 111 is provided with two The right frame groove 1110, the upper surface of the right frame groove 1110 is provided with a lower rotation groove 1112, the lower rotation groove 1112 is provided with two, the upper surface of the left support frame 112 is provided with a left frame groove 1120, and the left frame groove 1120 is provided with a left frame groove 1120. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com