Novel electronic component thermal resistance test fixture

A technology of electronic components and test fixtures, which is applied to workpiece clamping devices, parts of electrical measuring instruments, measuring devices, etc., and can solve problems such as pin welding contact, short circuit of electronic components, and inability to test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

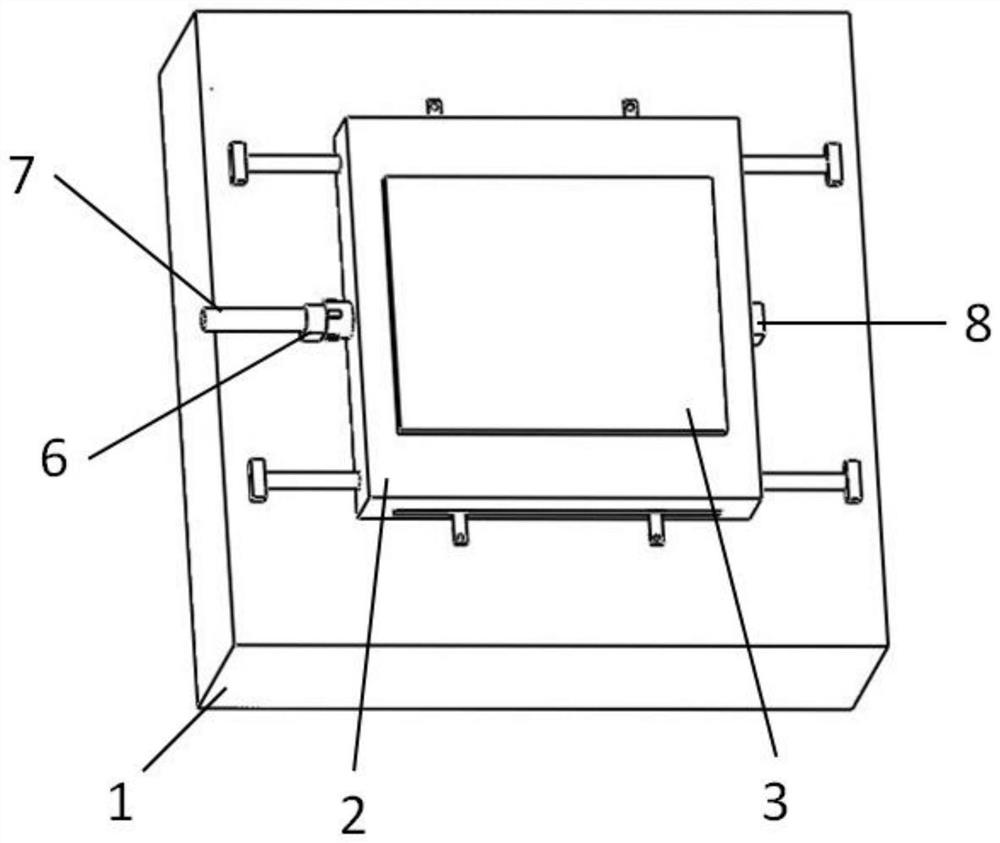

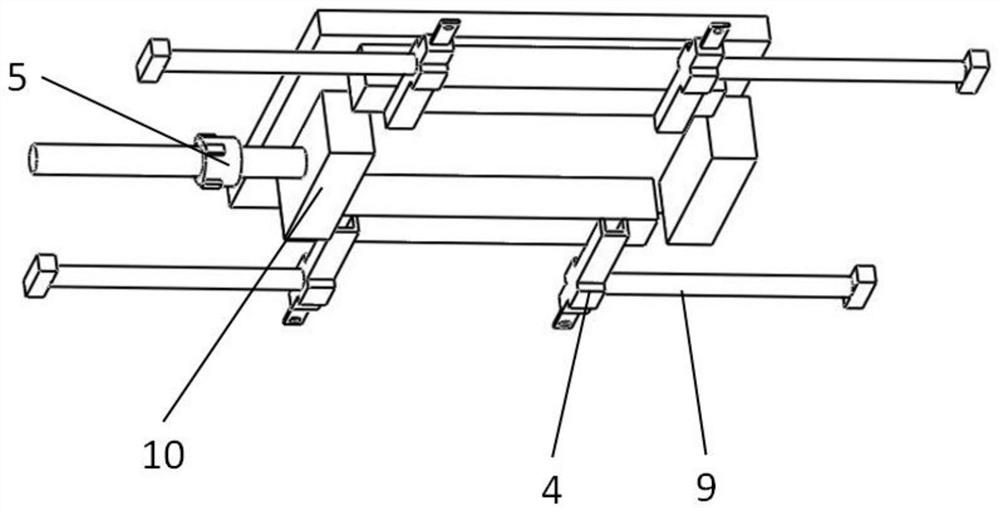

[0022] The invention provides a new type of thermal resistance test fixture for electronic components, the structure of which is as follows: figure 1 and figure 2 As shown, it includes a base 1, a slider guide rail 2 and a cover plate 3; the base 1 is a square structure, and the slider guide rail 2 is placed at the center of the base 1; the slider guide rail 2 is placed above the The cover plate 3 is fixed by the front guide rail positioning block 6 and the rear guide rail positioning block 8 respectively on both sides; several conductive sliders 4 are slidably connected in the internal guide rails on both sides of the slider guide rail 2; A conductive slider bar 9 is vertically and fixedly connected to the slider 4 ; a component fixing slider 10 is placed in the slider guide rail 2 , and a screw rod 7 is vertically fixedly connected to the fixed slider 10 .

[0023] Specifically, the slider guide rail 2 has a cavity up and down, and a joint guide rail hole is opened on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com