Chip signal testing device and method based on solder ball array packaging

A technology of solder ball array packaging and signal testing, which is applied in the direction of measuring devices, measuring device shells, and electronic circuit testing, etc., can solve the problems of signal distortion, error, and inductive or capacitive load errors without considering the lead impedance matching relationship, etc. To achieve the effect of improving reliability and avoiding noise coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

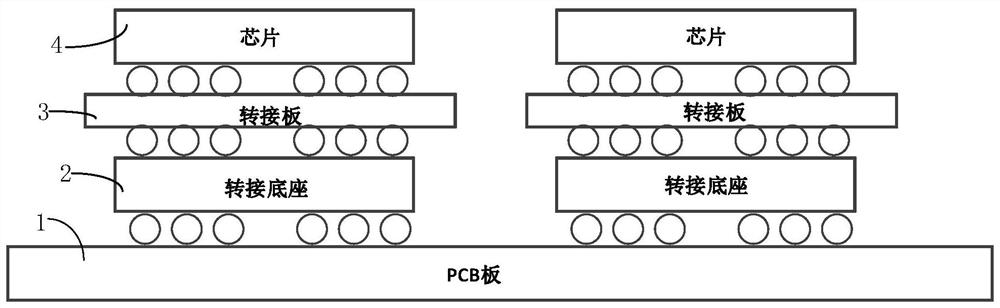

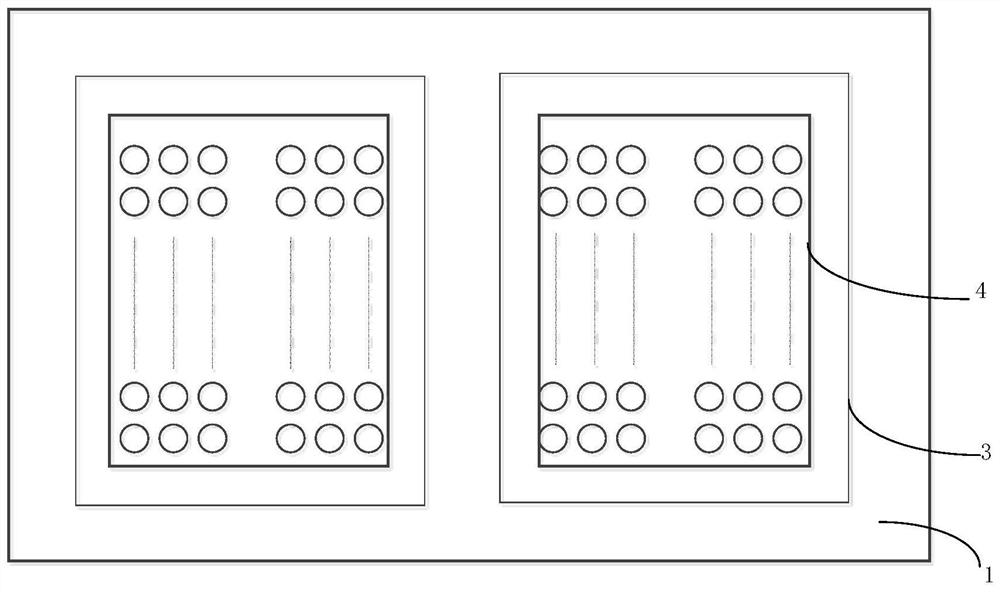

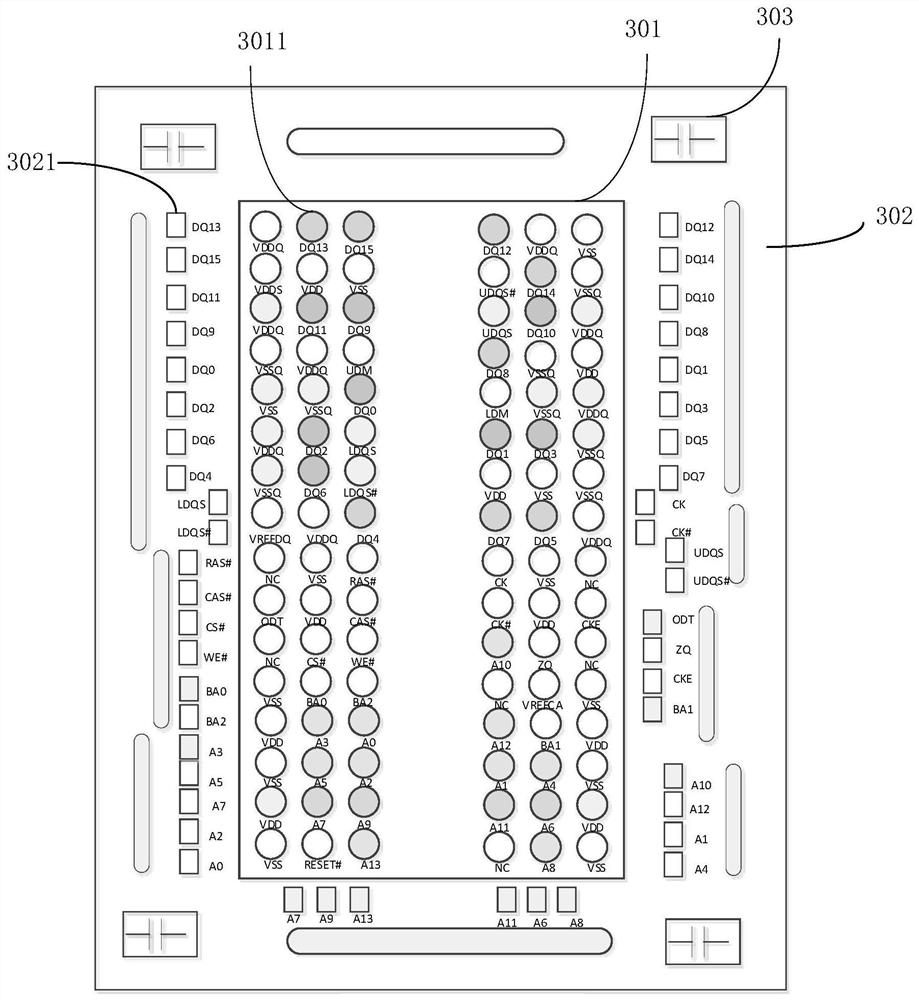

[0031] Such as Figure 1 to Figure 4 As shown, the chip signal testing device based on solder ball array packaging in this embodiment includes an adapter base 2, an adapter board 3, an active probe 5 and an oscilloscope 6; the bottom side of the adapter base 2 and the PCB board where the chip 4 is located The pads of 1 are connected correspondingly to raise the pads of PCB 1; the bottom side of the adapter board 3 and the top side of the adapter base 2 are connected by solder balls, and the top side of the adapter board 3 is provided with pads. The pads of the adapter board 3 include a connection terminal 3011 for connecting with the chip 4 to be tested through solder balls and a test terminal 3021 connected to the connection terminal 3011 , and the test terminal 3021 is connected to the oscilloscope 6 through the active probe 5 .

[0032] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com