Contactor locking device

A locking device and contactor technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of complexity, troublesome installation, and many installation parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

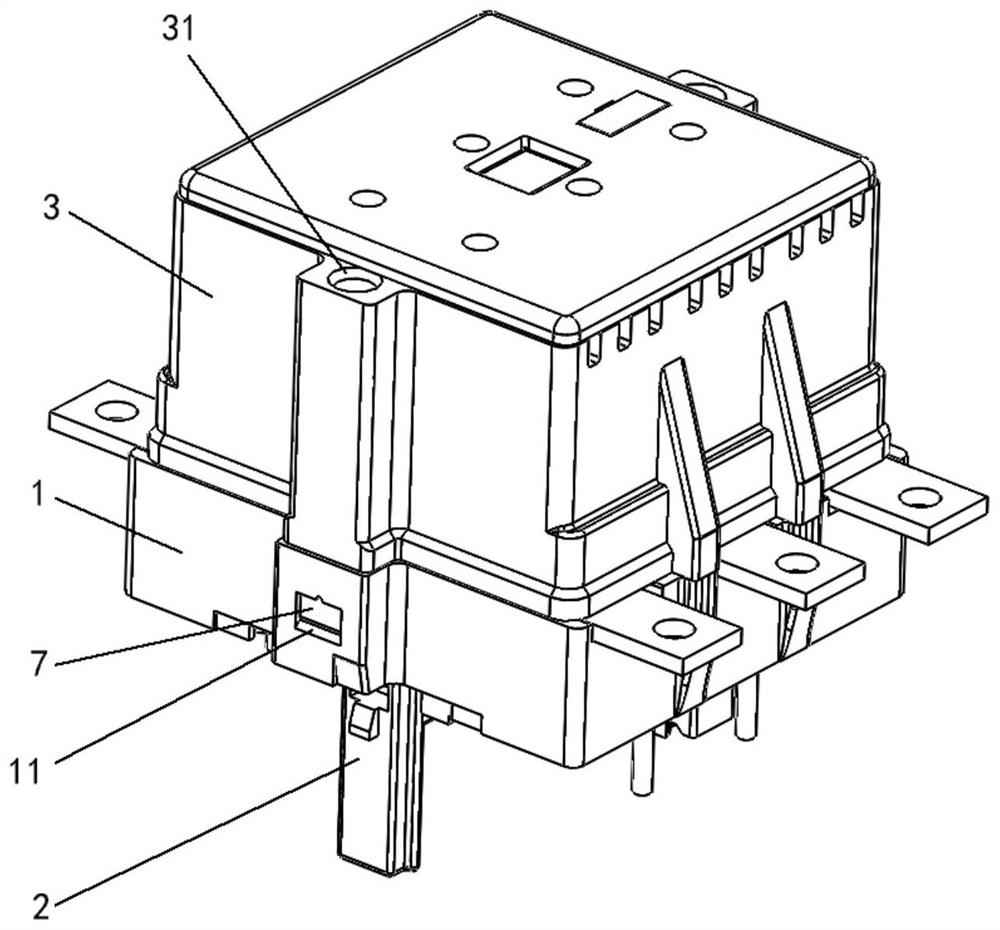

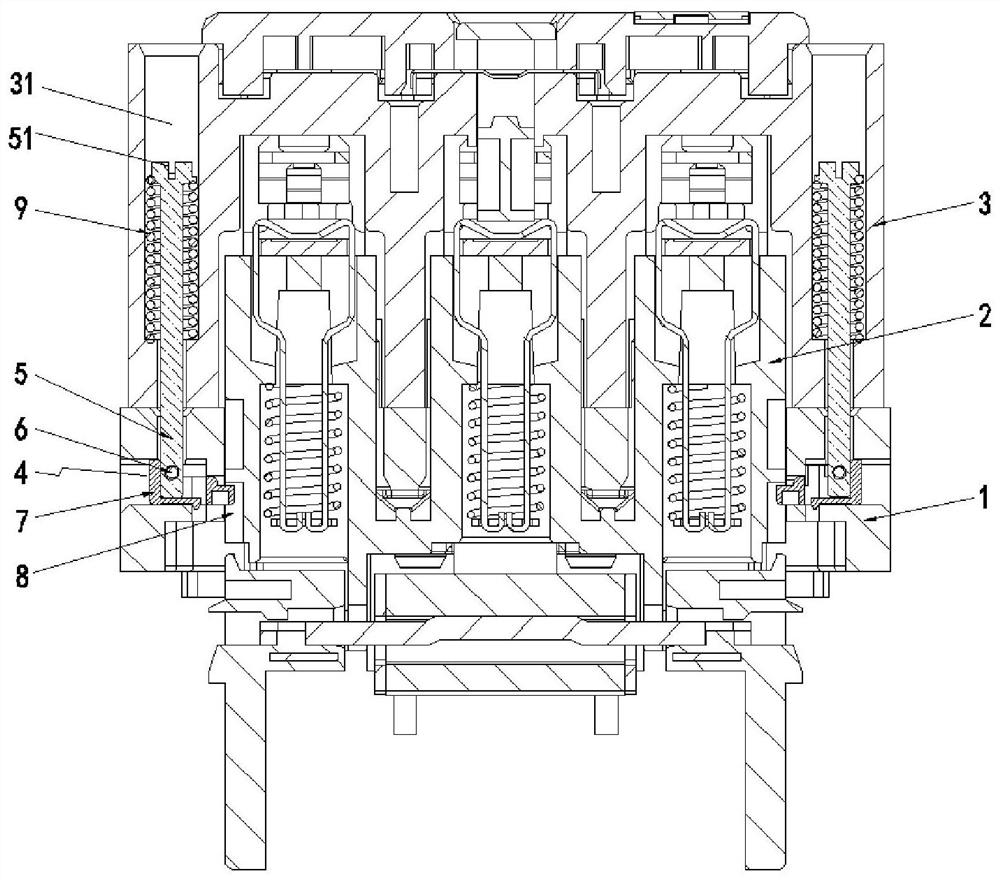

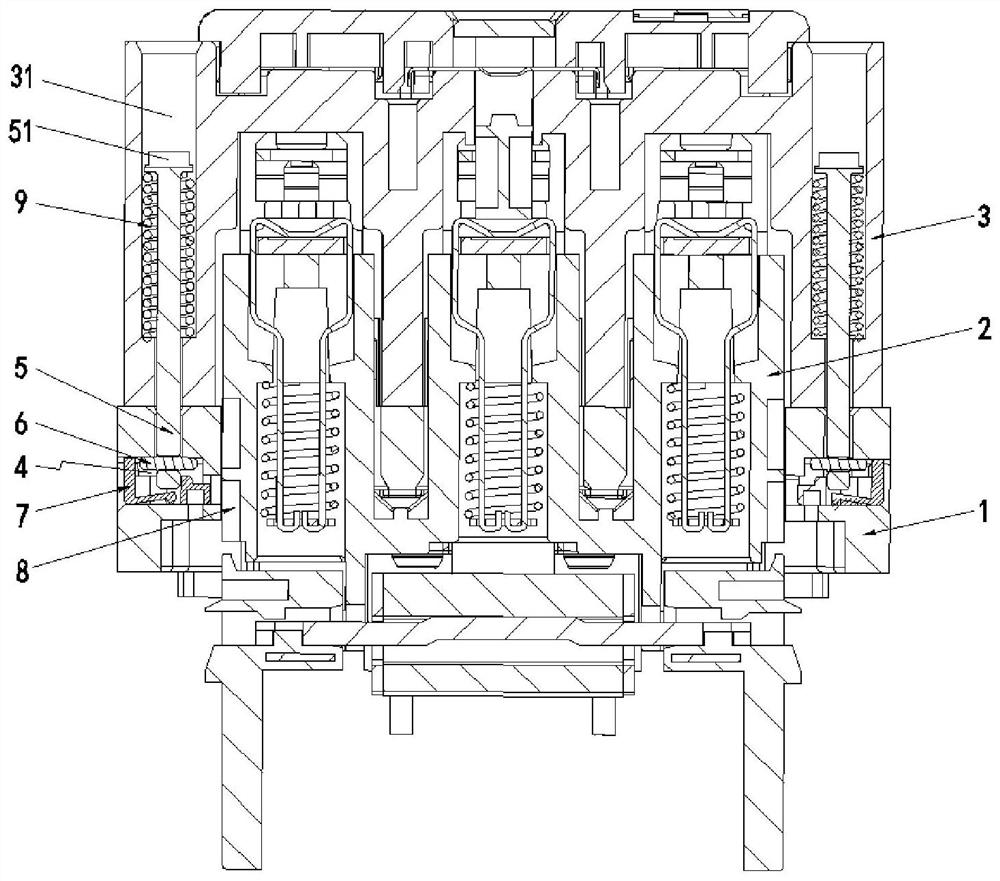

[0039] This embodiment provides as Figure 1-9 The shown contactor locking device includes a base 1, a contact support 2 and an arc extinguishing cover 3, and also includes:

[0040] The installation structure includes installation grooves 4 arranged on both sides of the top of the base 1, and an operating rod 5 which is rotated and passed between the installation groove and the arc extinguishing cover, and is arranged on the operating rod. The bottom end is suitable for inserting into the stopper 6 in the installation groove. When the stopper 6 rotates forward or reverse with the operating rod 5, it has a limit fit with the installation groove 4. To maintain the fixed position where the relative position of the base 1 and the arc chute 3 is fixed, and the detachment position where the limit fit is released from the installation groove 4;

[0041] The locking assembly includes a socket hole 11 that is provided on one or both side walls of the base 1 and communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com