Flip vacuum wafer film pasting device

A film sticking device and wafer technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as crushing wafers, dropping, and reducing the safety of wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

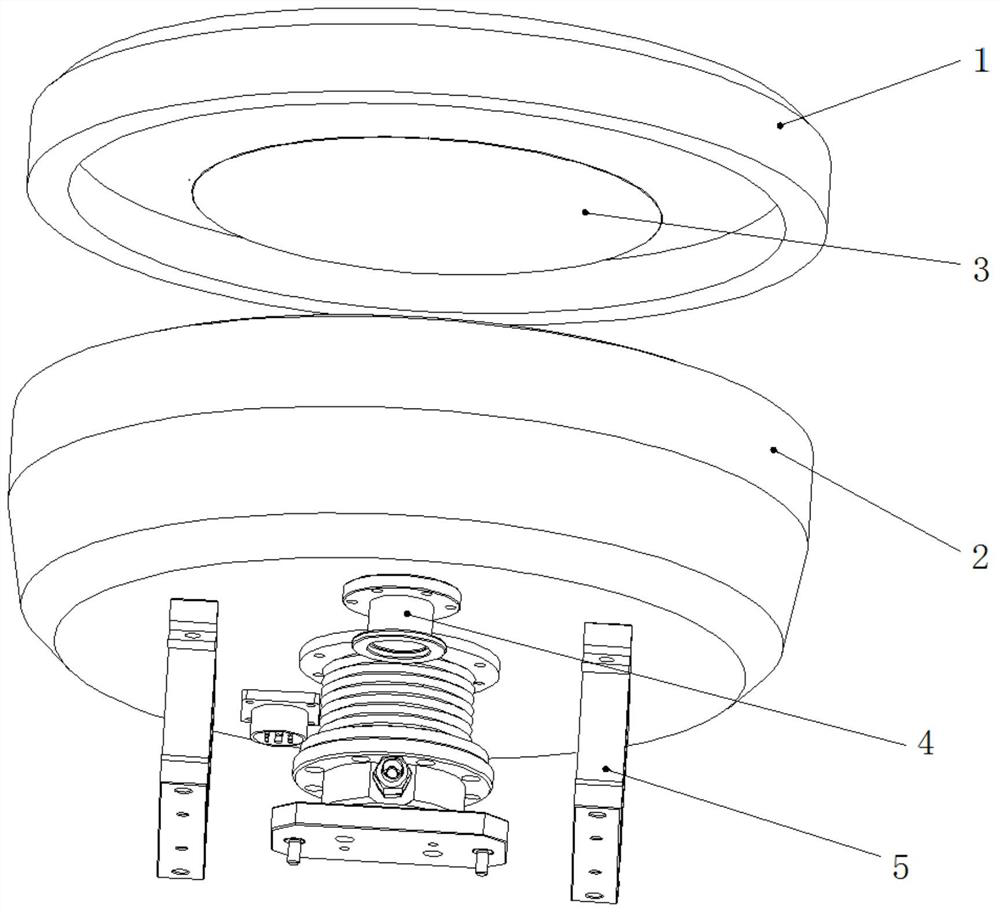

[0025] Such as figure 1 As shown, this embodiment provides a flip-chip vacuum wafer attaching device, the device includes an upper vacuum chamber 1 and a lower vacuum chamber 2, and the upper vacuum chamber 1 and the lower vacuum chamber 2 are respectively provided with an upper vacuum interface and a lower vacuum interface 4 , the upper vacuum interface and the lower vacuum interface 4 are independently connected to the vacuum suction equipment, and the outer side of the lower vacuum chamber 2 is provided with a fixed bracket 5 for fixing the lower vacuum chamber 2. The inner vacuum areas of the upper vacuum chamber 1 and the lower vacuum chamber 2 are both cylindrical, with the same diameter and larger than the diameter of the wafer 3 .

[0026] The upper vacuum chamber 1 is provided with an adsorption structure for absorbing the circuit board surface of the wafer 3, and the adsorption structure includes a vacuum adsorption structure. Specifically, in this embodiment, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com