Material liquid concentration device and material liquid evaporator thereof

A concentrating device and evaporator technology, applied in evaporator accessories, evaporation, multi-effect evaporation, etc., can solve the problems of reducing evaporation efficiency, increasing energy consumption, and inability to effectively increase evaporation area, so as to improve evaporation efficiency and reduce heat Emissions and the effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The feed liquid concentration device in the present invention promotes the evaporation of the solvent in the low-concentration feed liquid through the joint action of heating and negative pressure vacuum, and realizes the concentration and purification of the feed liquid.

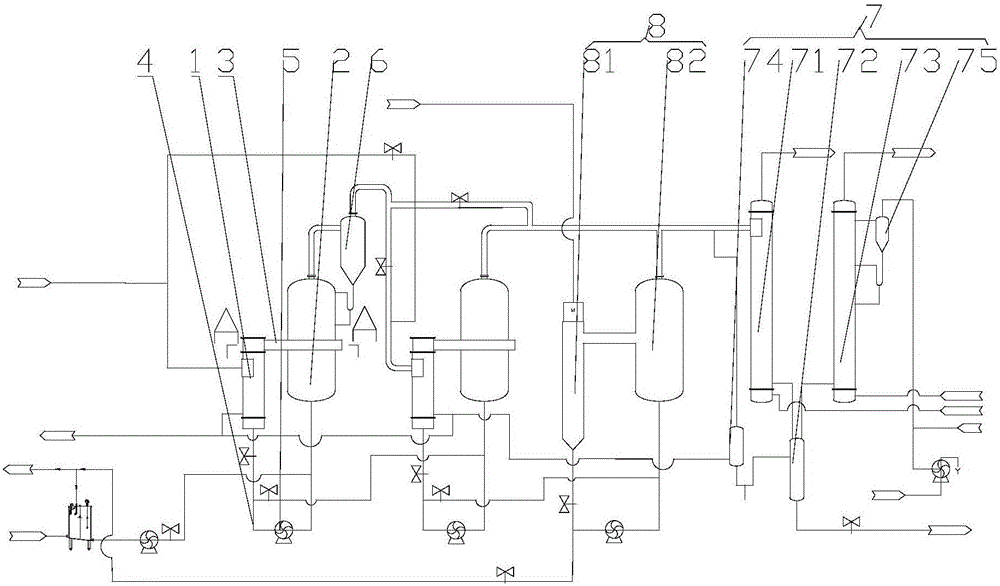

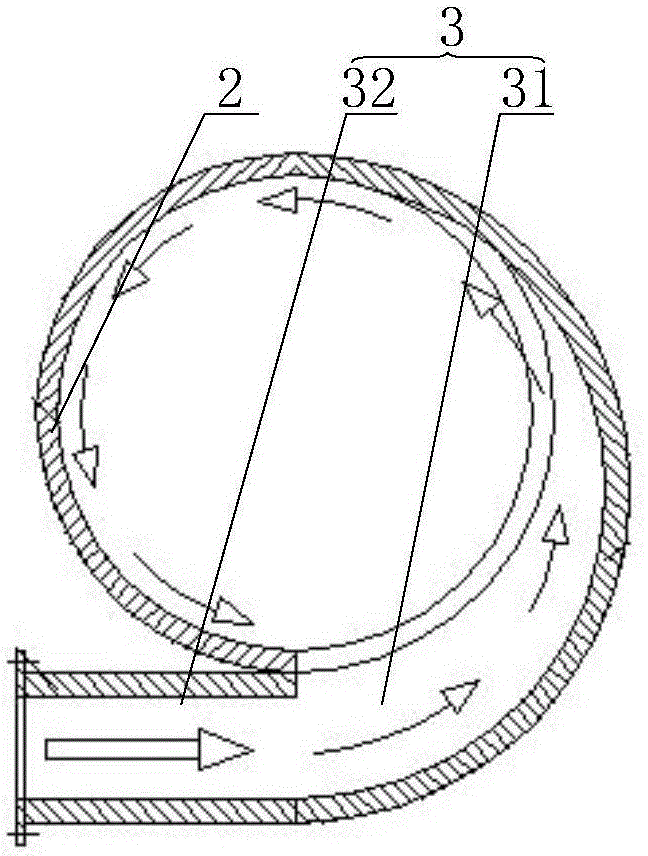

[0026] figure 1 It is a schematic diagram of the feed liquid concentration device of the present invention, and it can be seen from the figure that it has a feed liquid evaporator and a cooling assembly connected in series with the feed liquid evaporator. Among them, the feed liquid evaporator realizes the concentration and purification of the feed liquid, and the cooling component realizes subsequent heat recovery and utilization (the cooling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com