Control method of dish washing machine and dish washing machine

A control method and dishwasher technology, which are applied to tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, household cleaning devices, etc., which can solve the problems of poor drying effect, high energy consumption, and ineffective drying procedures. Match the actual situation of the tableware and other issues to achieve a good drying effect and solve the effect of complaints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

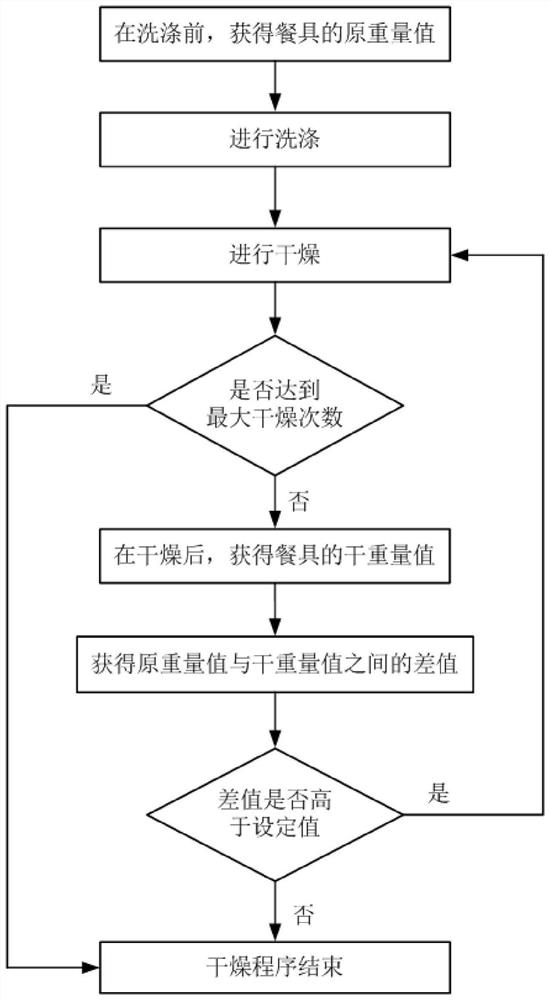

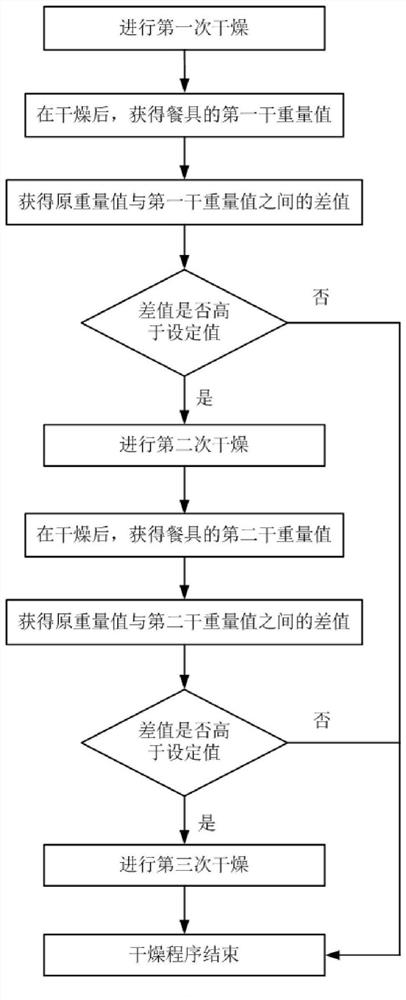

[0033] see figure 1 with figure 2 An embodiment of the present invention provides a method for controlling a dishwasher. During use, the dishwasher includes a washing phase and a drying phase, wherein the washing phase includes a main washing phase and a rinsing phase.

[0034] Before washing, the original weight value of the dishes is obtained. According to the original weight value of the tableware, the corresponding washing parameters are obtained, including the water inlet level (or water inlet volume), the washing operation time and the speed of the shower, and then the washing is performed according to the washing parameters, and the washing stage will not be described too much here.

[0035] Drying is performed after washing, and after drying, the dry weight value of the tableware is obtained; if the difference between the original weight value and the dry weight value is higher than the set value, drying is performed again.

[0036] By obtaining the original weight ...

Embodiment 2

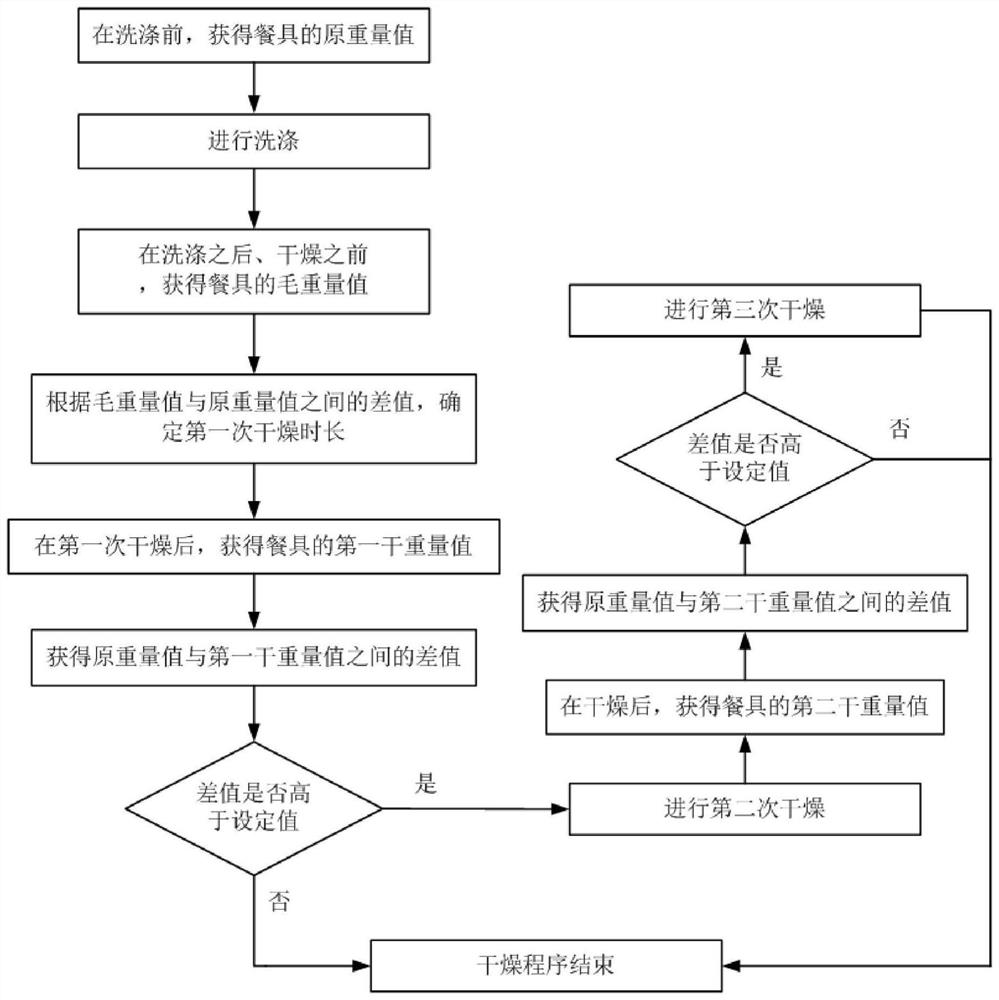

[0059] image 3 The second embodiment is shown, and for the sake of brevity, only the differences between the second embodiment and the first embodiment are described. The difference is that after washing and before drying, the gross weight value of the tableware is obtained; according to the difference between the gross weight value and the original weight value, the duration of the first drying is determined.

[0060] After washing and before drying, there is moisture on the tableware. At this time, the gross weight value of the tableware includes the weight of moisture, so that the gross weight value must be greater than the original weight value. The difference between the gross weight value and the original weight value is the moisture weight. Determine the length of the first drying according to the weight of the water, making the setting of the time more targeted. Theoretically, after the first drying, the original weight value will be closer to the first dry weight va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com