Rubber sealing strip preparing and forming process

A technology of rubber sealing strip and molding process, which is applied in metal processing, household utensils, and other household utensils, etc. It can solve the problems that it is difficult to control the consistent depth of grooves, reduce the applicability of equipment, and reduce the production efficiency of rubber sealing strips. Consistent, production-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

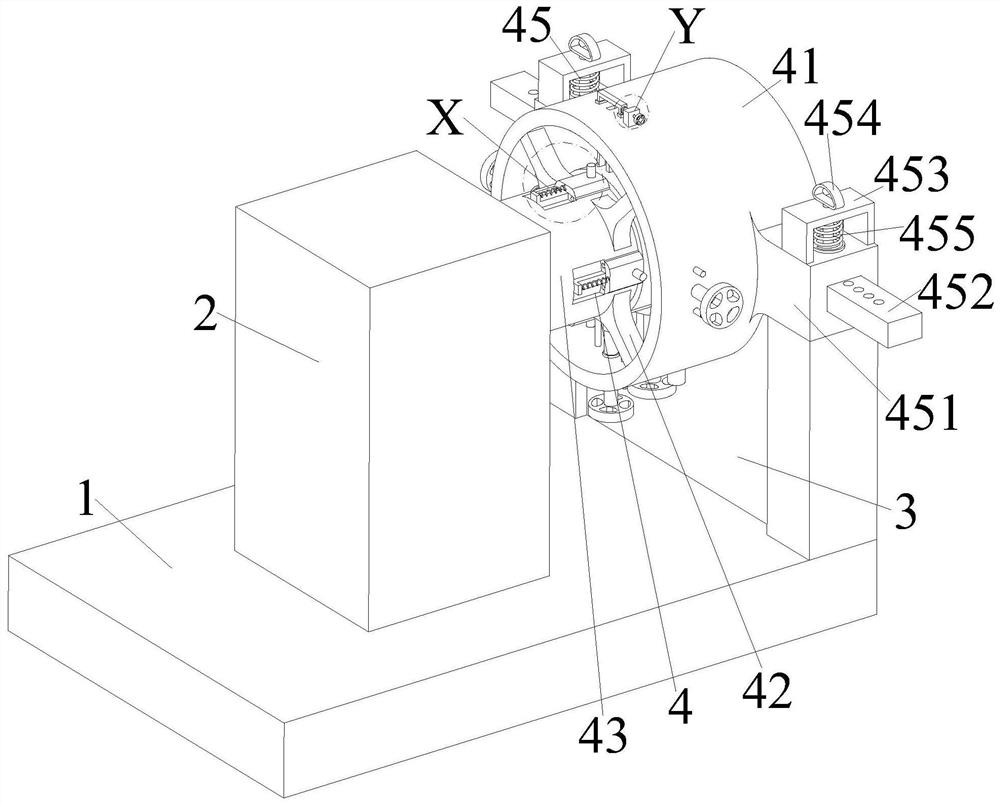

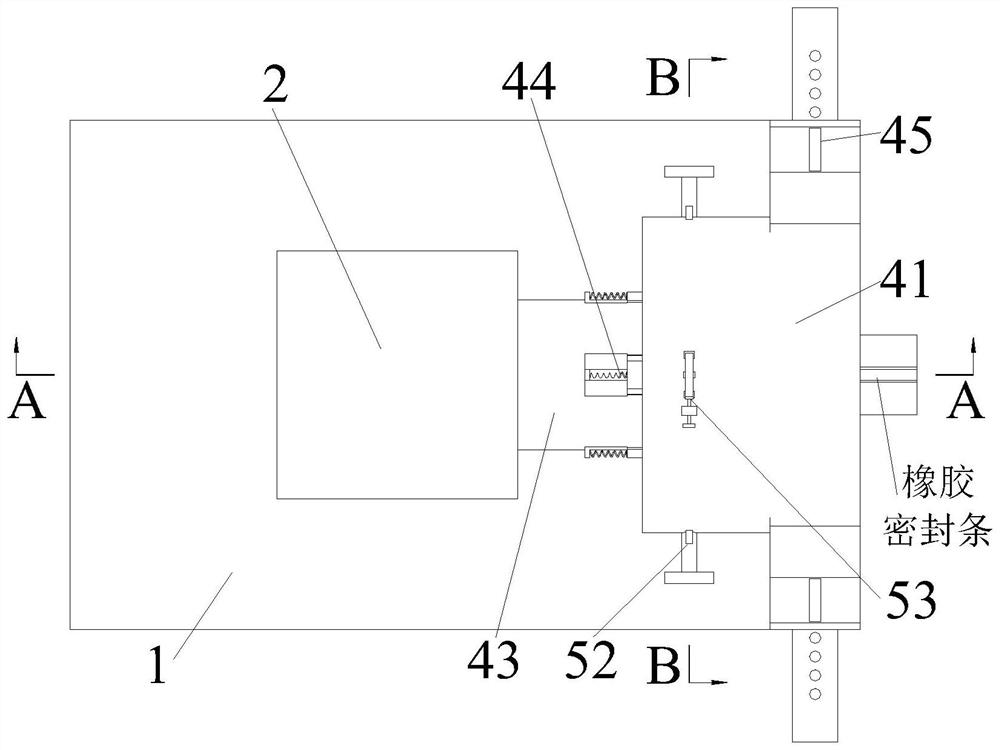

[0040] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

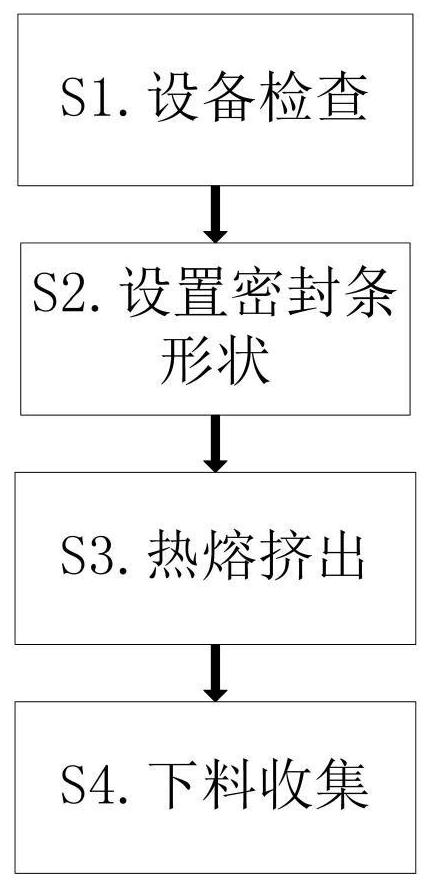

[0041] A preparation and molding process for a rubber sealing strip, the specific preparation and molding process is as follows:

[0042] S1. Equipment inspection: check the rubber sealing strip production equipment before using it to make rubber sealing strips;

[0043] S2. Set the shape of the sealing strip: after the equipment inspection is completed, manually adjust the circular forming device 4 and the square forming device 5, so that the equipment can process rubber sealing strips of different shapes through the circular forming device 4 and the square forming device 5;

[0044] S3. Hot-melt extrusion: After the shape adjustment of the rubber sealing strip is completed, the raw material of the rubber sealing strip is placed in the extruder 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com