Pantograph and pantograph head assembly

A bow head and component technology, applied in the field of pantograph and bow head components, can solve problems such as poor contact, affecting the normal charging of electric vehicles, and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

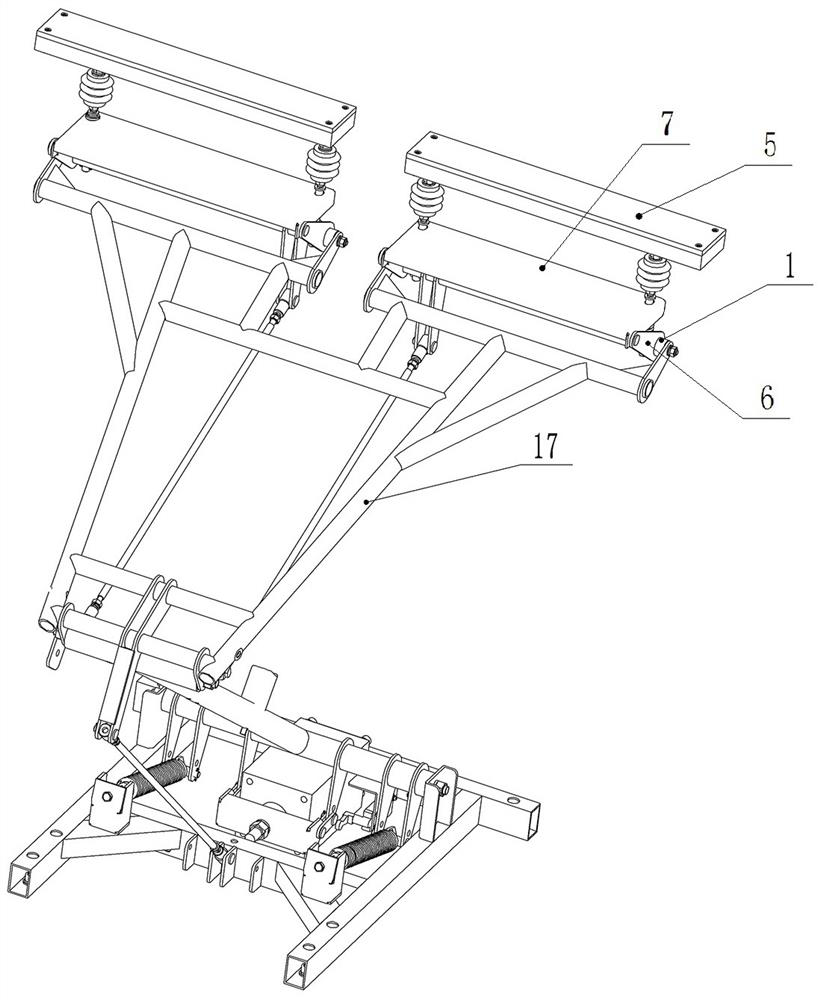

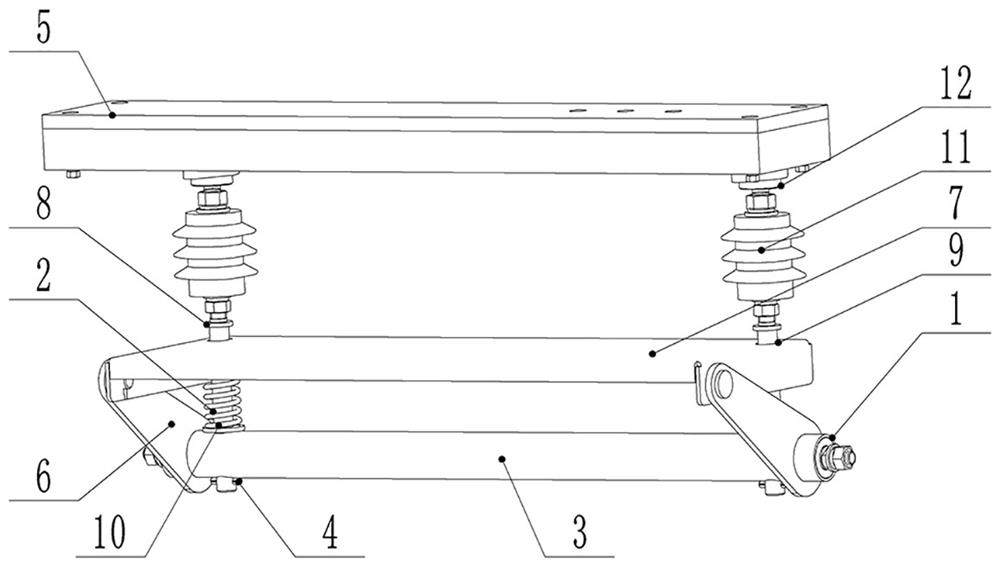

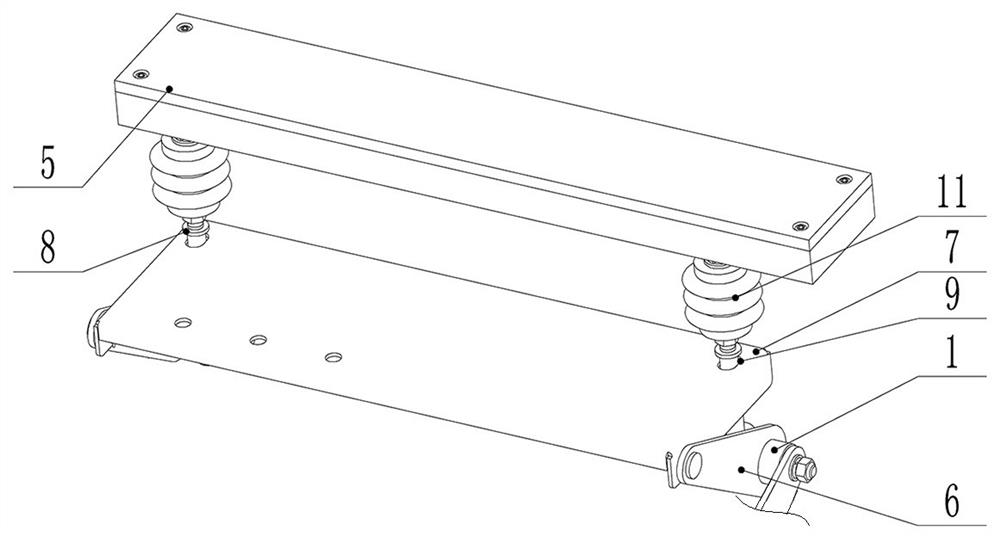

[0032] Such as figure 1 and figure 2 As shown, the bow head assembly includes a bow head support 1 and a support rod 2 guided and assembled on the bow head support 1. The bow head support 1 includes a rotating shaft 3 for transmission connection with the drive mechanism 17 of the pantograph. The rotating shaft 3 is provided with There are two through holes arranged at intervals along its length direction, the through holes on the rotating shaft 3 are radial through holes, two support rods 2 are provided, and pass through corresponding through holes along the up and down direction, the One end of the plate is provided with a pin shaft 4, and the pin shaft 4 is engaged with the rotating shaft 3 so as to restrict the support rod 2 from passing through the through hole from the upper side.

[0033] Such as figure 2 As shown, the upper end of the support rod 2 is fixedly connected with the conductive plate 5 so that the conductive plate 5 can guide and move relative to the bow ...

specific Embodiment 2

[0040] The difference from Embodiment 1 is that the bow bracket can also include a bent plate, the bent plate is formed by a horizontal plate and a vertical plate, the horizontal plate is provided with a through hole, the support rod is guided and assembled in the through hole, and the balance plate is hinged On the vertical plate, and the hinge axis extends along the length direction of the conductive plate; or a straight plate can be included between the bow heads, there is a through hole above the straight plate, the support rod is assembled in the through hole, and the balance pressure plate is hinged on the The edge of the straight plate is away from the through hole, and the hinge axis extends along the length direction of the conductive plate.

specific Embodiment 3

[0042] It differs from Embodiment 1 in that three or four crank arms on the rotating shaft can be arranged at intervals along the length direction of the rotating shaft; or when the size of the crank arm along the length direction of the rotating shaft is large, the crank arm One arm can also be provided, and the crank arm is arranged at the middle position in the length direction of the rotating shaft. The specific number and location of the crank arms can be selected arbitrarily according to the actual situation, as long as the structural stability of the connection between the rotating shaft and the balance plate can be satisfied, and the rotating shaft does not affect the guiding movement of the support rod in the up and down direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com