Double-pump single-outlet type emulsion packaging bottle

A technology for packaging bottles and lotions, applied in the field of packaging bottles, can solve the problem of not being able to selectively use different liquids, and achieve the effect of reducing the number and space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

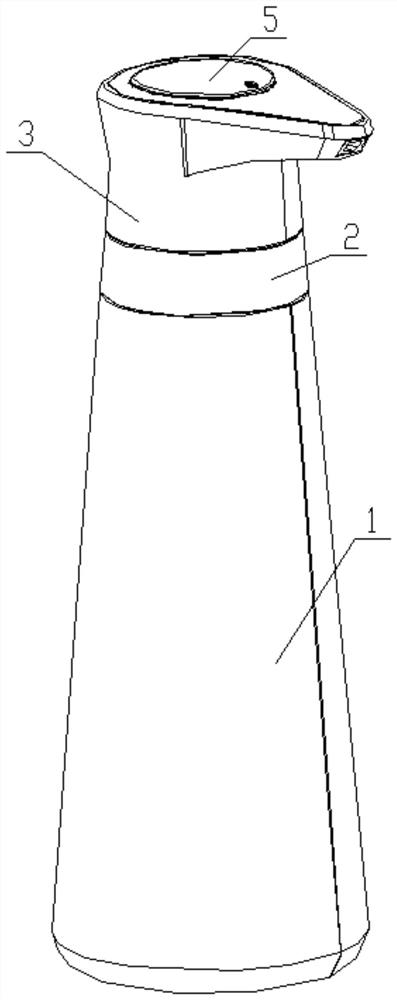

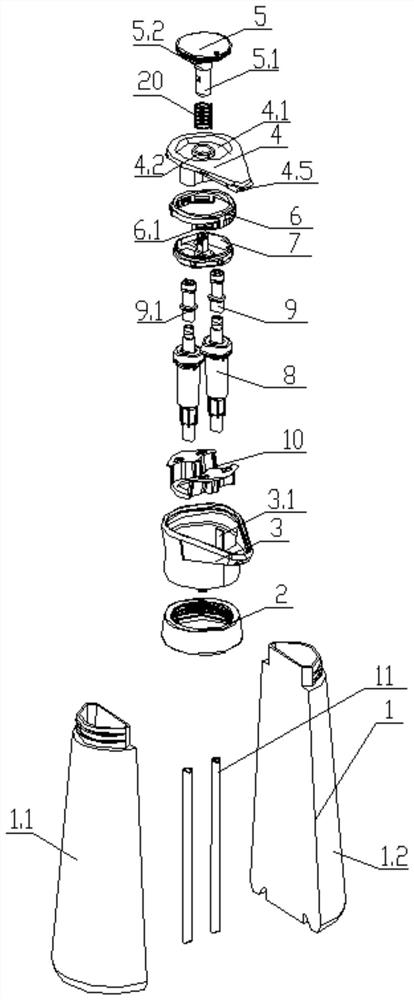

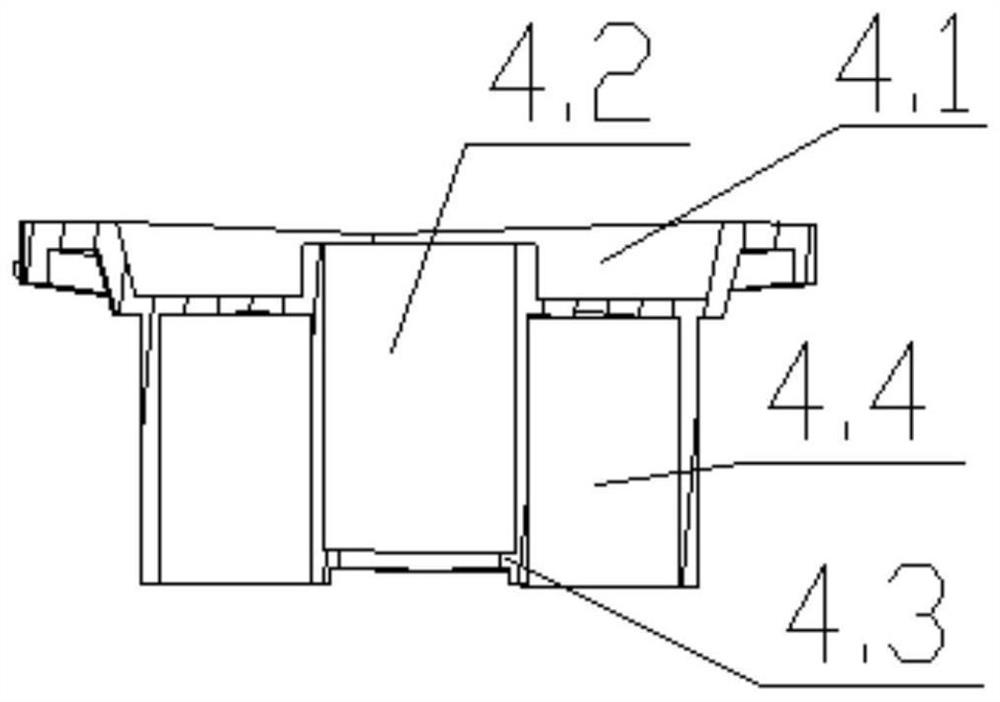

[0025] Such as Figure 1-10 As shown, the present invention discloses a double-pump emulsion packaging bottle. The packaging bottle is provided with a left pumping liquid level, a right pumping liquid level and an empty space, and specifically includes a bottle body 1, which is in the shape of a truncated cone. The body is formed by combining the left bottle body 1.1 and the right bottle body 1.2 and connecting each other. The upper ends of the left bottle body 1.1 and the right bottle body 1.2 are both open. 3. The screw cap 2 and the head shell 3 are tightly connected and communicated with each other. The screw cap 2 is threadedly connected to the upper port of the bottle body 1. The upper end of the head shell 3 is an opening and is sealed and connected to the liquid outlet. Cover 4, a circular groove 4.1 and a pressing channel 4.2 that is concentric with the circular groove 4.1 and penetrates the liquid upper cover 4 are provided on the upper surface of the liquid outlet c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap