Film unloading system and method for flexible vertical diaphragm wall construction

A technology of anti-seepage wall and membrane system, which is applied to artificial islands, sheet pile walls, water conservancy projects, etc., and can solve problems such as complex geological conditions and difficulties in laying down HDPE membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

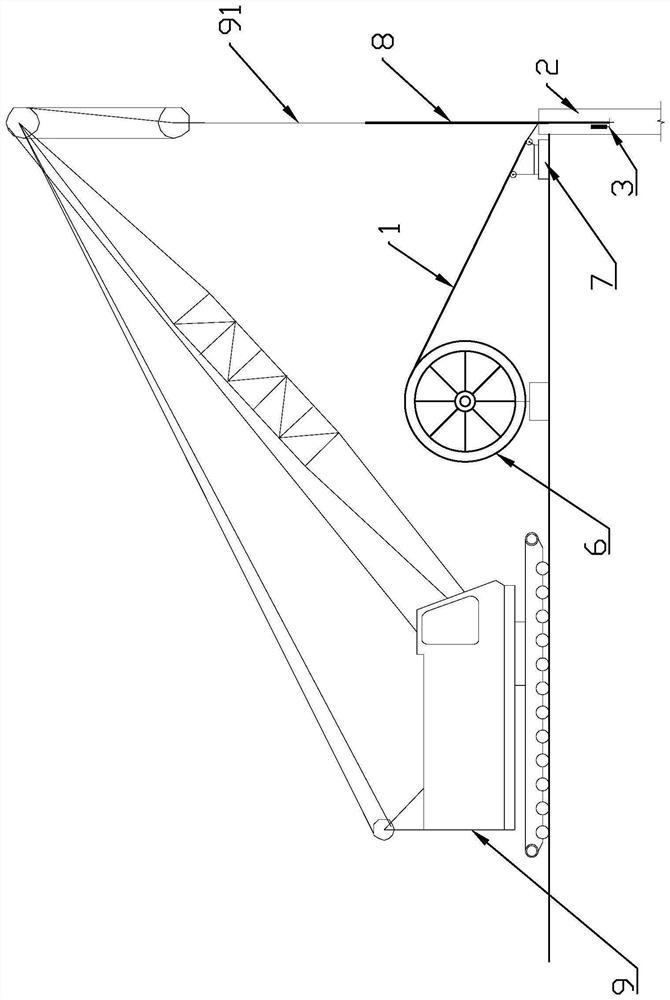

[0033] Such as Figure 1-Figure 3 As shown, the present invention provides a kind of lower membrane system for the construction of flexible vertical cutoff wall, which is used to vertically place HDPE membrane 1 in underground cavity 2, which includes:

[0034] The bottom fixing device is fixedly connected with the bottom end of the HDPE film 1, and is used to make the HDPE film 1 hang down naturally under the action of gravity; wherein, the bottom fixing device includes an angle steel 3, and one edge of the angle steel 3 is vertically arranged and connected to the HDPE film One side of the bottom end of HDPE film 1 is pasted, and the other side of the bottom end of HDPE film 1 is pasted with flat steel bead 4. Tightly connected so as to be fixedly connected with the bottom end of the HDPE film 1; the other side of the angle steel 3 extends upwards obliquely, thereby forming an acute angle at the bottom end of the angle steel 3; Several vertical holes 31;

[0035] Film reel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com