Stepless Pressure Regulation Method for Turbocharger Actuator

A technology of turbochargers and actuators, which is applied in the direction of machines/engines, combustion engines, safety devices, etc., and can solve problems such as the inability to realize the stepless pressure regulation of actuators, the pressure regulation value interval value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

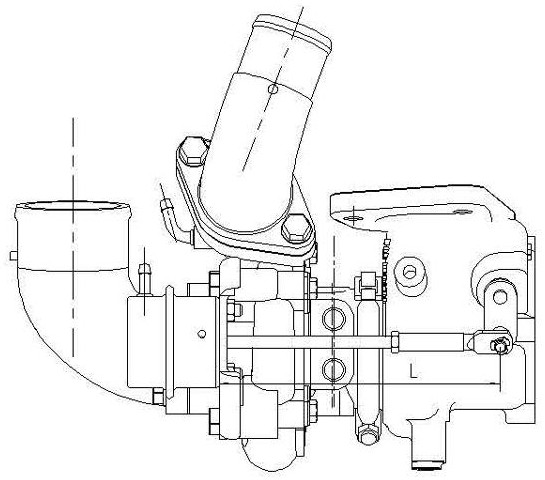

[0027] A method for stepless pressure regulation of a turbocharger actuator is provided, and the schematic diagram of the actuator installed on the turbocharger is shown in figure 1 As shown, the stepless pressure regulation method specifically includes the following steps:

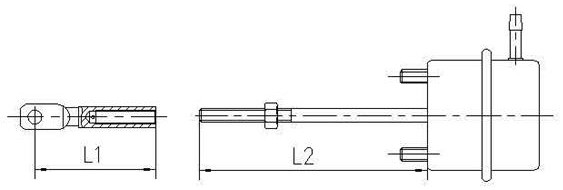

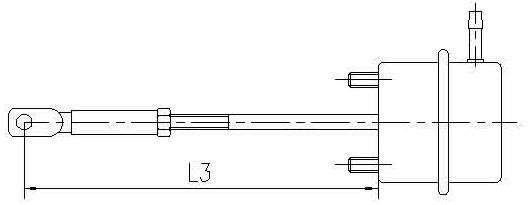

[0028] S1. Pressurize the air cavity of the actuator head, install the connecting hole of the actuator sleeve to the transmission pin, obtain the distance L value from the installation positioning surface of the actuator to the connecting hole of the sleeve, and the distance L between the connecting hole of the sleeve and the sleeve itself The distance L1 value of the end surface, the distance L2 value of the distance from the installation positioning surface to the end surface of the push rod in the free state of the actuator;

[0029] S2. Obtain the real-time pressure and stroke data relational formula Y=aX+b in the theoretical working process of the actuator, where Y is the air chamber filling pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com