Electrostatic chuck device and degumming machine

An electrostatic chuck and placement surface technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of small edge adsorption force and large electrostatic chuck adsorption force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

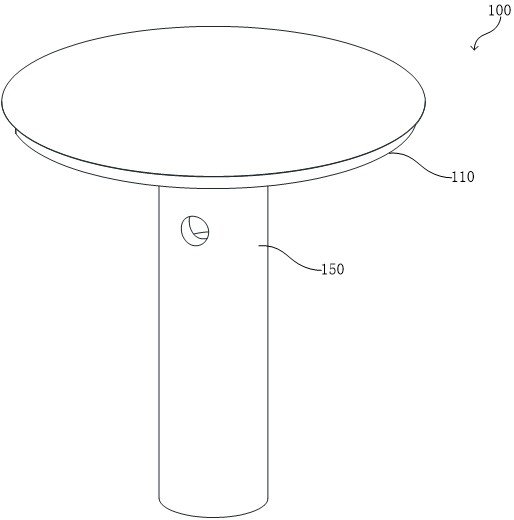

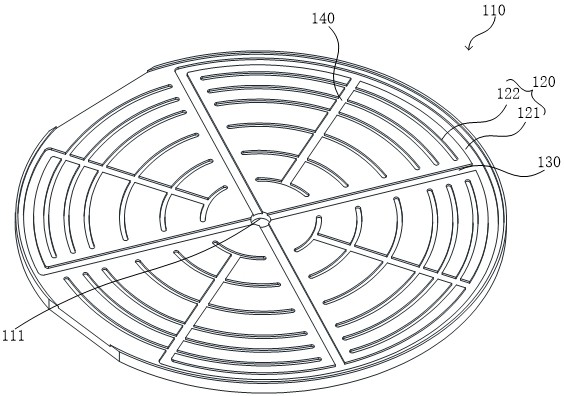

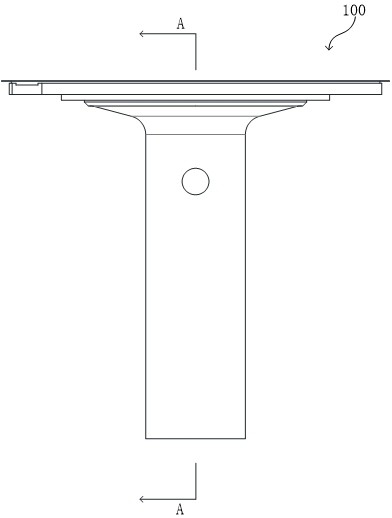

[0037] see figure 1 , which is a schematic structural view of the electrostatic chuck device 100 provided in the first embodiment of the present invention, including: an electrostatic chuck 110 . combine figure 2 , the electrostatic chuck 110 is provided with a placement surface, and a plurality of circumferential air passages 120 , a plurality of radial air passages 130 and a plurality of return air passages 140 are arranged on the placement surface. Among them, a plurality of circumferential air passages 120 form a concentric multi-layer structure in the radial direction; a plurality of radial air passages 130 communicate with the air hole 111 in the center of the placement surface and the outermost circumferential air passage 120, and communicate with the remaining circumferential air passages. The air passage 120 is blocked; there are multiple return air passages 140 , and each return air passage 140 communicates with all the circumferential air passages 120 between any ...

no. 2 example

[0071] The second embodiment of the present invention provides a glue remover (not shown in the figure), including the electrostatic chuck device 100 provided in the first embodiment. Wherein, the electrostatic chuck device 100 can be used for fixing the wafer during the process of wafer degluing by the degumming machine, for example, installed in the degumming cavity.

[0072] Preferably, the degumming machine is a fully automatic degumming machine or a semi-automatic degumming machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com