A method for repairing and replacing hydraulic disc spring operating mechanism of 500kv circuit breaker

A technology of operating mechanism and replacement method, applied in switchgear, electrical components, etc., can solve the problems of different structural forms, different lengths of slings, low efficiency, etc., to ensure stability, high replacement efficiency, and ensure safe transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

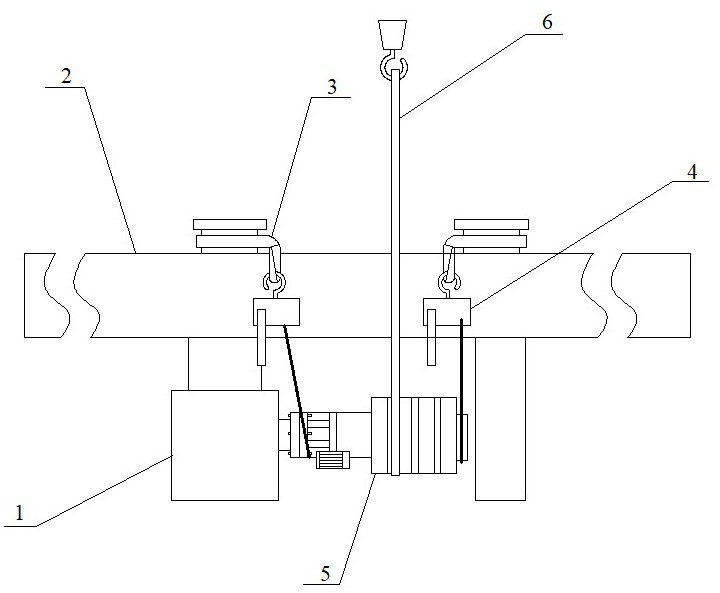

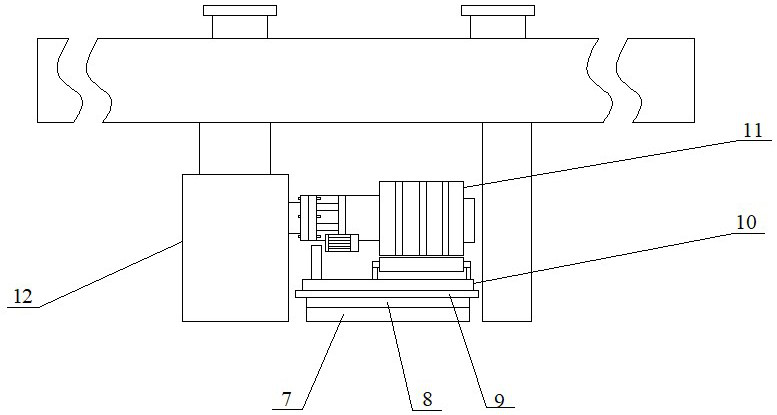

[0035] like Figure 2~3 As shown, a method for overhauling and replacing a hydraulic disc spring operating mechanism of a 500kV circuit breaker includes the following steps:

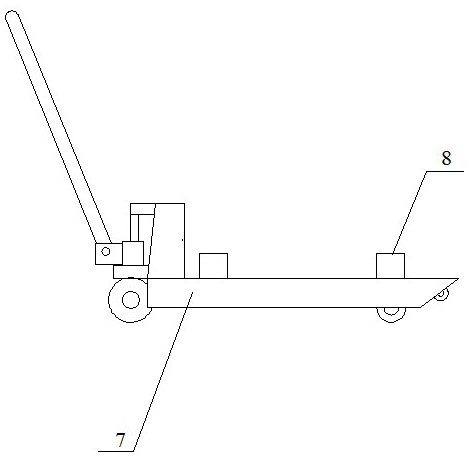

[0036] S1: Hydraulic Cart 7 ( figure 2 Only the plate body part of the hydraulic trolley is shown) after placing the support block 8, the support plate 9 and the maintenance and replacement platform 10 in sequence, they are pushed to the bottom of the hydraulic disc spring operating mechanism 11 to be repaired and replaced;

[0037] S2: Press the handle of the hydraulic cart 7 several times to raise the height of the hydraulic cart 7 until the disc spring portion of the hydraulic disc spring operating mechanism 11 is in contact with the support module on the upper part of the maintenance and replacement platform 10;

[0038] S3: Start the maintenance and replace the telescopic module on the upper part of the platform 10 to stably support the energy storage part of the hydraulic disc spring operating me...

Embodiment 2

[0044] A method for overhauling and replacing a hydraulic disc spring operating mechanism of a 500kV circuit breaker, comprising the following steps:

[0045] S1: After placing the support block, the support plate and the inspection and replacement platform on the hydraulic trolley in sequence, they are pushed to the bottom of the hydraulic disc spring operating mechanism to be repaired and replaced;

[0046] S2: Press the handle of the hydraulic trolley several times to raise the height of the hydraulic trolley until the disc spring part of the hydraulic disc spring operating mechanism is in contact with the support module on the upper part of the maintenance and replacement platform;

[0047] S3: Start the maintenance and replace the telescopic module on the upper part of the platform to stably support the energy storage part of the hydraulic disc spring operating mechanism;

[0048] S4: Remove the fixing bolts connecting the 500kV circuit breaker and the hydraulic disc spri...

Embodiment 3

[0058] A method for overhauling and replacing a hydraulic disc spring operating mechanism of a 500kV circuit breaker, comprising the following steps:

[0059] S1: After placing the support block, the support plate and the inspection and replacement platform on the hydraulic trolley in sequence, they are pushed to the bottom of the hydraulic disc spring operating mechanism to be repaired and replaced;

[0060] S2: Press the handle of the hydraulic trolley several times to raise the height of the hydraulic trolley until the disc spring part of the hydraulic disc spring operating mechanism is in contact with the support module on the upper part of the maintenance and replacement platform;

[0061] S3: Start the maintenance and replace the telescopic module on the upper part of the platform to stably support the energy storage part of the hydraulic disc spring operating mechanism;

[0062] S4: Remove the fixing bolts connecting the 500kV circuit breaker and the hydraulic disc spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com