Heat dissipation plate of inverter unit fluid radiator

A technology of inverter unit and radiator, which is applied in the direction of modification by conduction heat transfer, cooling/ventilation/heating transformation, etc., which can solve the limitation of the working capacity of heating devices, the difference in heat transfer efficiency of fins, and the low flow rate on the surface of fins, etc. problem, to achieve the effect of reducing variance, good uniformity, and uniform fluid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The fluid radiator of the inverter unit of the present invention may be an air-cooled radiator or a water-cooled radiator.

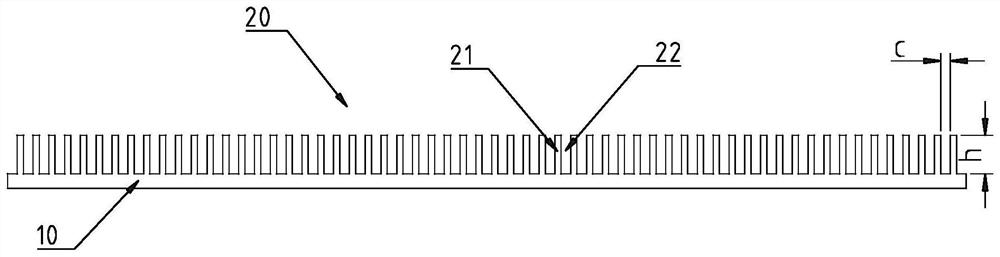

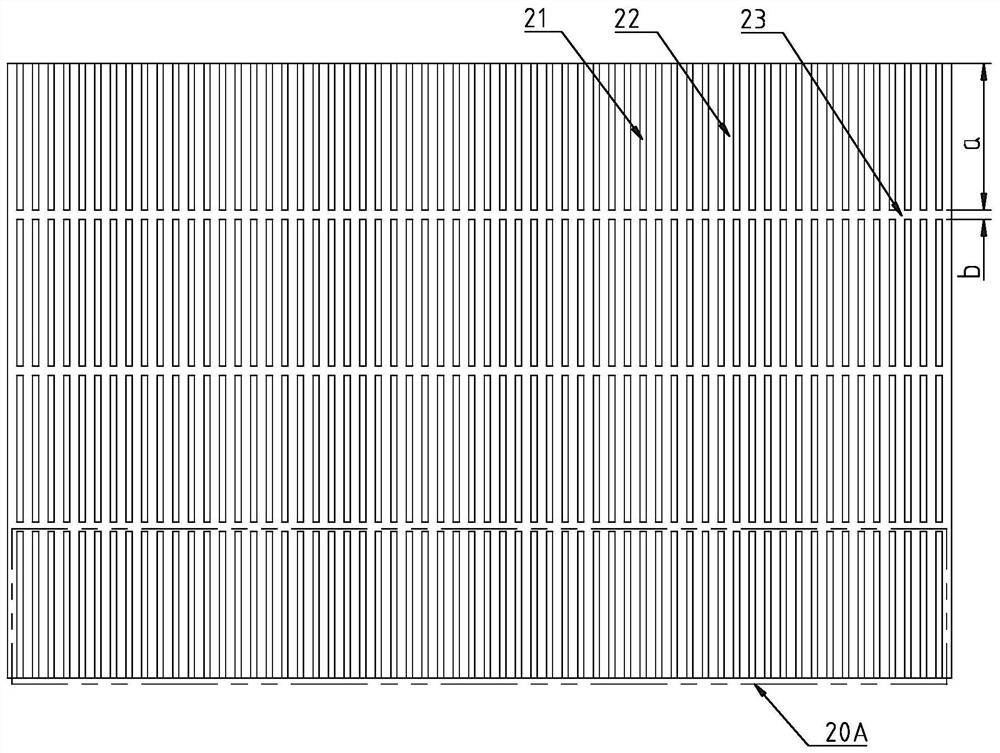

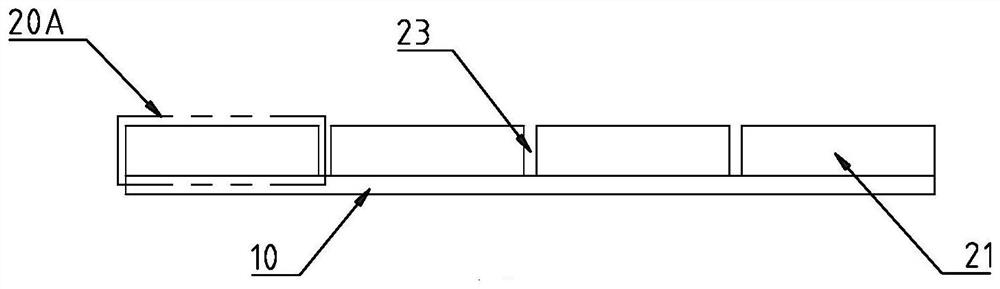

[0026] Embodiment 1 of the present invention The structure of the cooling plate of the water-cooled radiator of the inverter unit is as follows: Figure 1 to Figure 4 As shown, it includes a bottom plate 10 , a heat dissipation portion 20 arranged on the top surface of the top plate, and three horizontally arranged flow equalization grooves 23 . Such as Figure 4 As shown, the heating power device of the inverter unit is installed on the bottom surface of the base plate 10 .

[0027] The heat dissipation part 20 includes 60 fins 21 arranged longitudinally, the gaps between adjacent fins 21 are channels 22 for air flow, and the flow equalization groove 23 runs through the heat dissipation part 20 transversely, dividing the heat dissipation part 20 into four vertically Separate 4 cooling zones 20A. The depth of the flow equalizing groove 23 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com