An automatic batching device for meat processing

A technology for automatic batching and food processing, which is used in mixers with rotary stirring devices, accessories for mixers, transportation and packaging, etc. It can improve the mixing efficiency, improve the cleaning effect, and simplify the complexity of the equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed description is given in conjunction with specific embodiments and accompanying drawings.

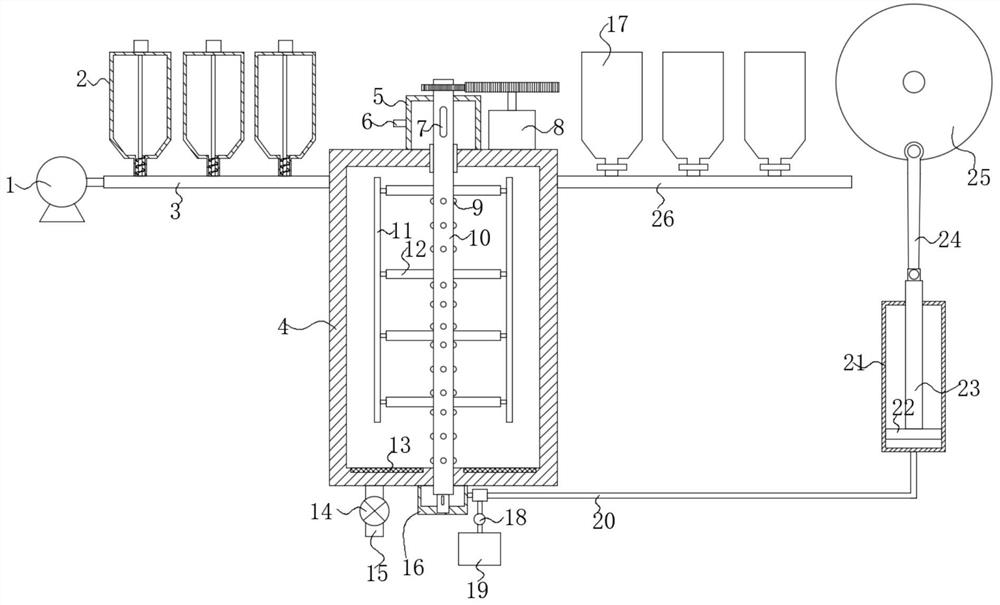

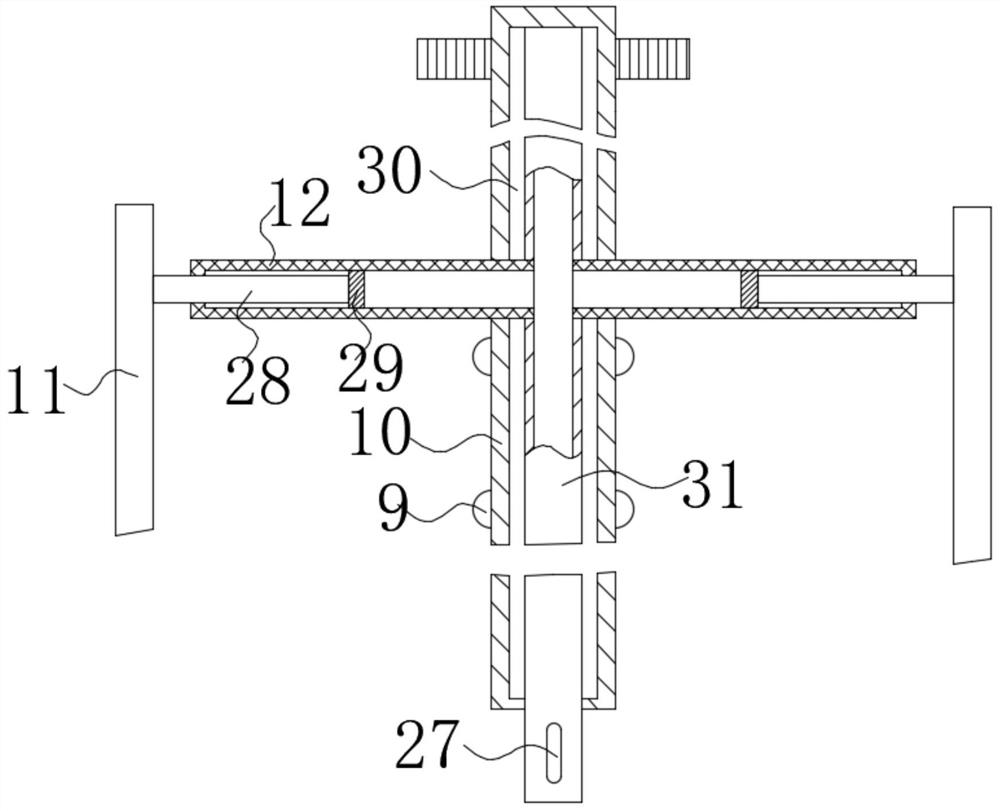

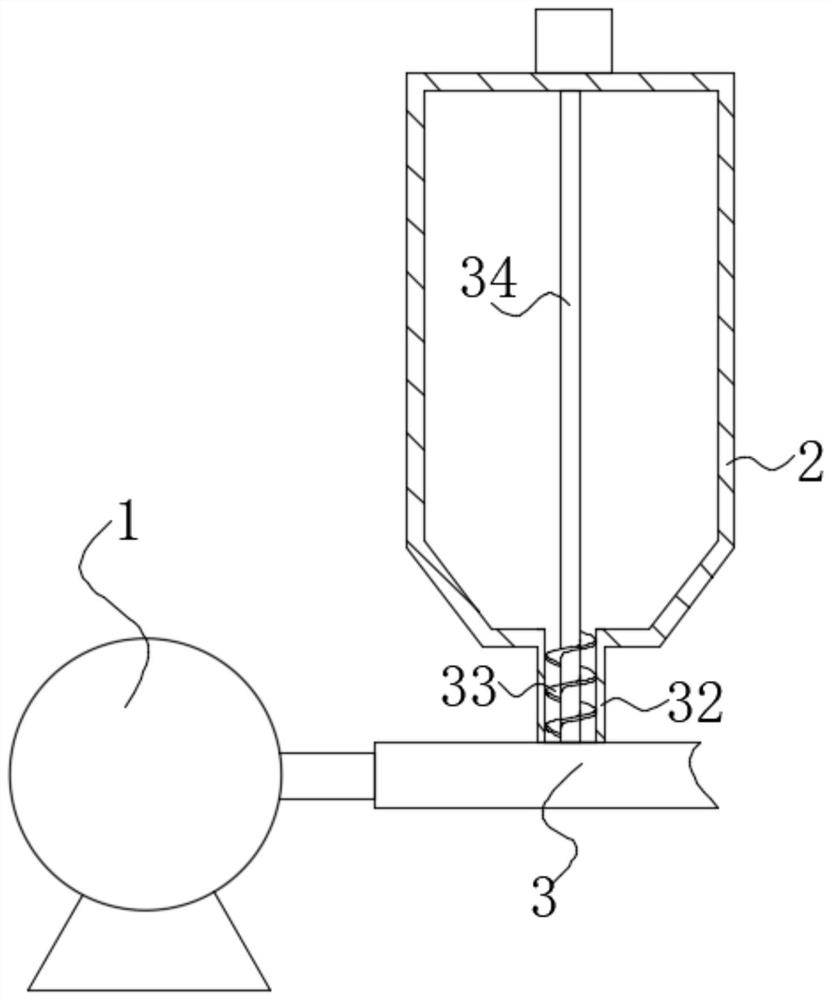

[0027] see figure 1 , this embodiment, an automatic batching device for meat food processing, including a mixing tank 4, a discharge valve 14 is fixedly installed at the discharge port 15 at the bottom of the mixing tank 4, and the mixing tank 4 is two up and down. A first sealing cover 5 and a second sealing cover 16 are respectively fixedly installed on the outer wall of the end, and an outer sleeve 10 is rotatably installed in the mixing tank 4, and the top end of the outer sleeve 10 is rotated through the first sealing cover 5. . The top side wall of the outer sleeve 10 is provided with a first flow hole 7 that communicates with the first sealing cover 5. An inner pipe 31 is coaxially arranged in the outer sleeve 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com