Welding gun protection device and welding equipment

A technology for protective devices and welding equipment, which is applied in welding equipment, welding protection devices, arc welding equipment, etc., and can solve problems such as inability to protect the torch head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

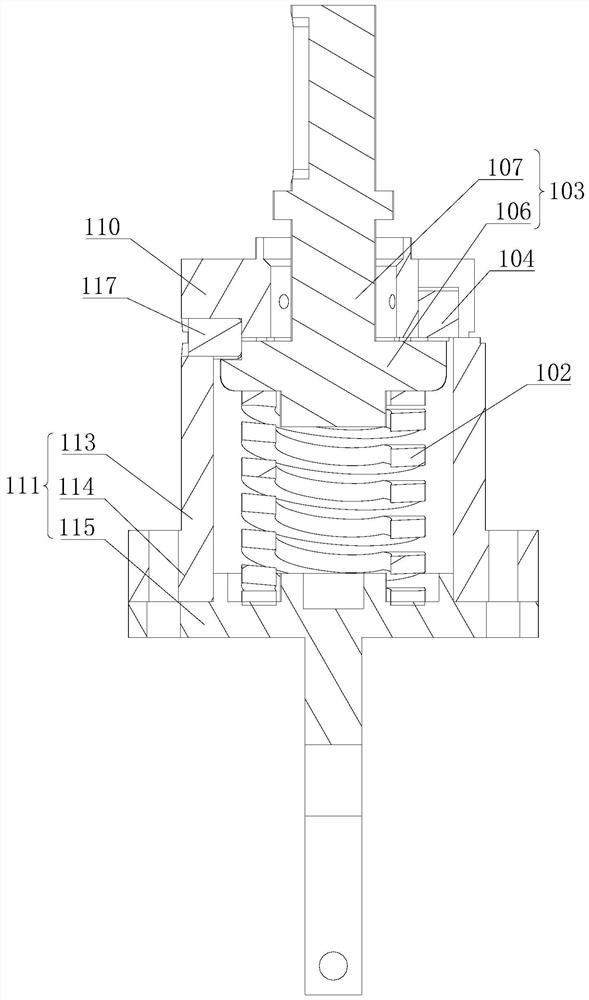

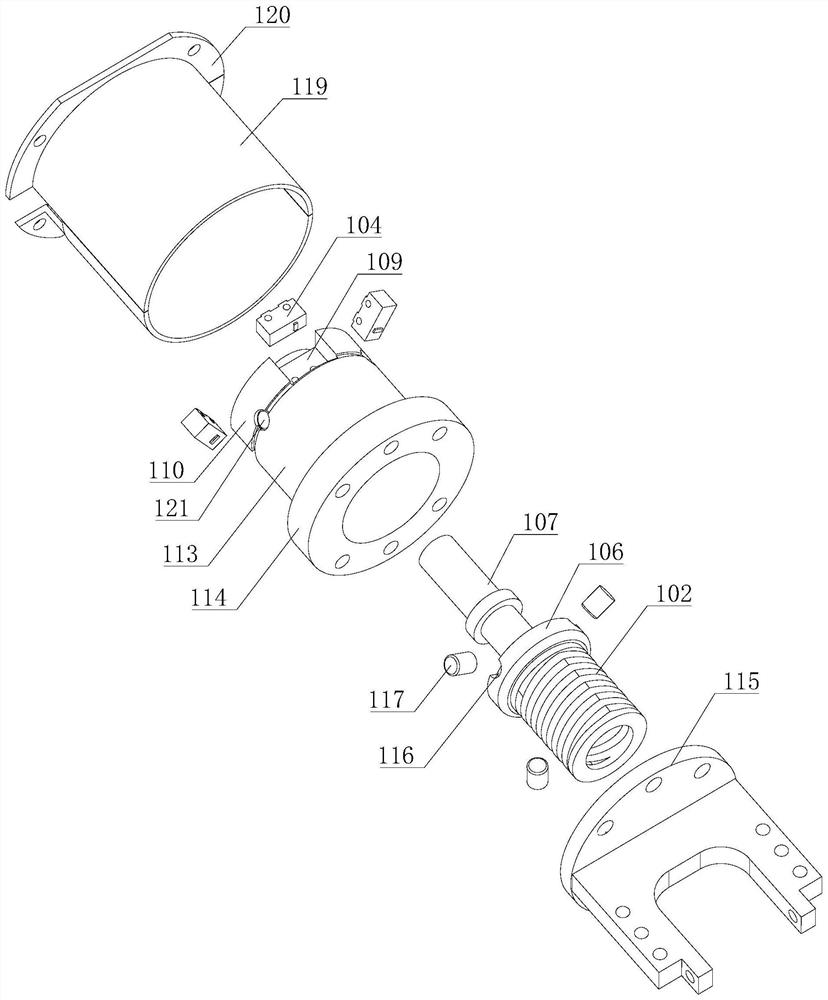

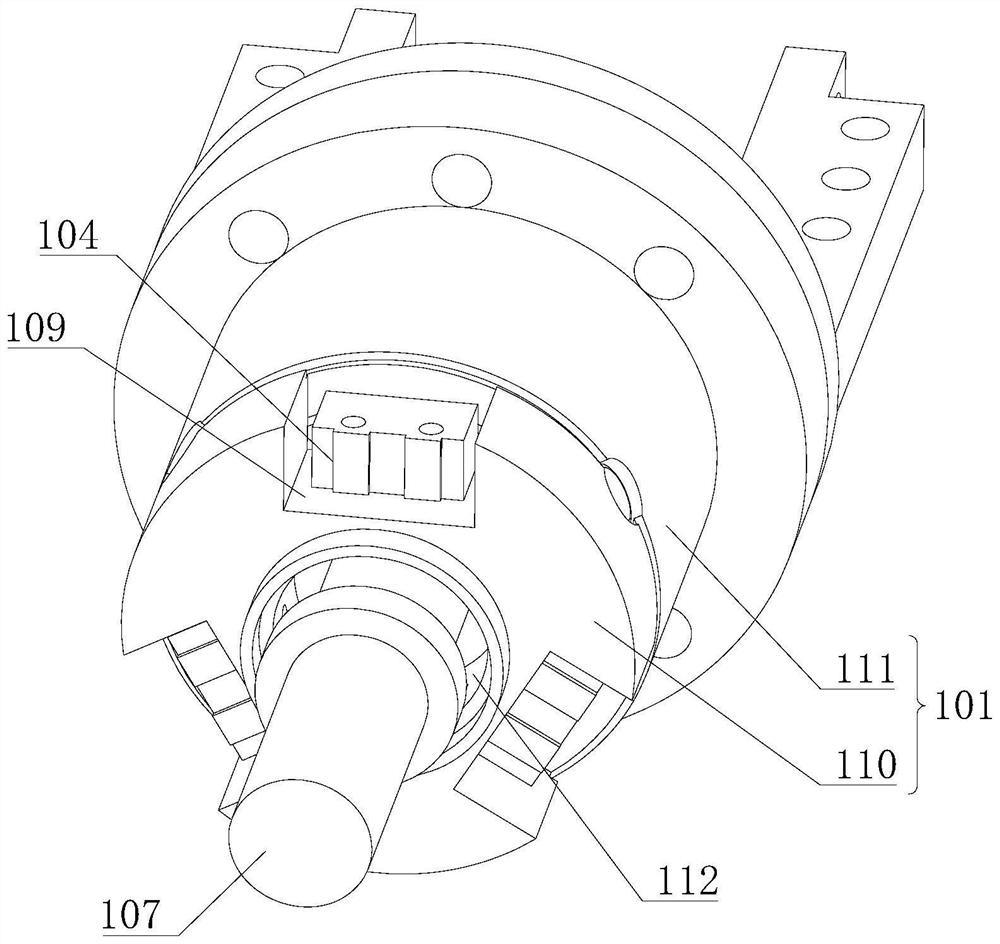

[0045] see Figure 1 to Figure 4 As shown, the welding torch protection device provided by the present application is used for welding equipment. The welding torch protection device includes a housing 101, an elastic member 102, a trigger 103 and a plurality of trigger switches 104; one end of the housing 101 is connected to a welding torch 105; the trigger 103 Including the abutment part 106 and the connection part 107, the abutment part 106 is located in the housing 101, the connection part 107 passes through the other end of the housing 101, and is connected with the body of the welding equipment, specifically, Figure 4 A partial structure 108 of the body of the welding device is shown in .

[0046] A plurality of trigger switches 104 are mounted on the housing 101 and arranged at intervals in the circumferential direction of the contact portion 106. Each trigger switch 104 is connected with an alarm device and a protection program of the welding equipment. Corresponds to...

Embodiment 2

[0061] The welding torch protection device in the second embodiment is an improvement on the basis of the above embodiment. The technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

[0062] In the optional solution of this embodiment, the abutment portion 106 is provided with a limit gap, and the housing 101 is formed with a limit pin 117 inserted into the limit gap; when the end of the limit gap away from the elastic member 102 is the first closed end When the limit pin 117 forms a gap with the first closed end; when the end of the limit gap close to the elastic member 102 is the second closed end, the limit pin 117 forms a gap with the second closed end.

[0063] In this example, see Figure 5 to Figure 7 As shown, the limit gap can have various structural forms, and is not limited to figure 2 with Figure 5 The groove structur...

Embodiment 3

[0072] Embodiment 3 of the present application provides a welding device, which includes the welding torch protection device of any one of the above embodiments, and thus has all the beneficial technical effects of the welding torch protection device of any one of the above embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com