3D printing process and 3D printer for metal dentures

A technology of 3D printers and dentures, applied in metal processing equipment, 3D object support structures, manufacturing tools, etc., can solve problems such as waste of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

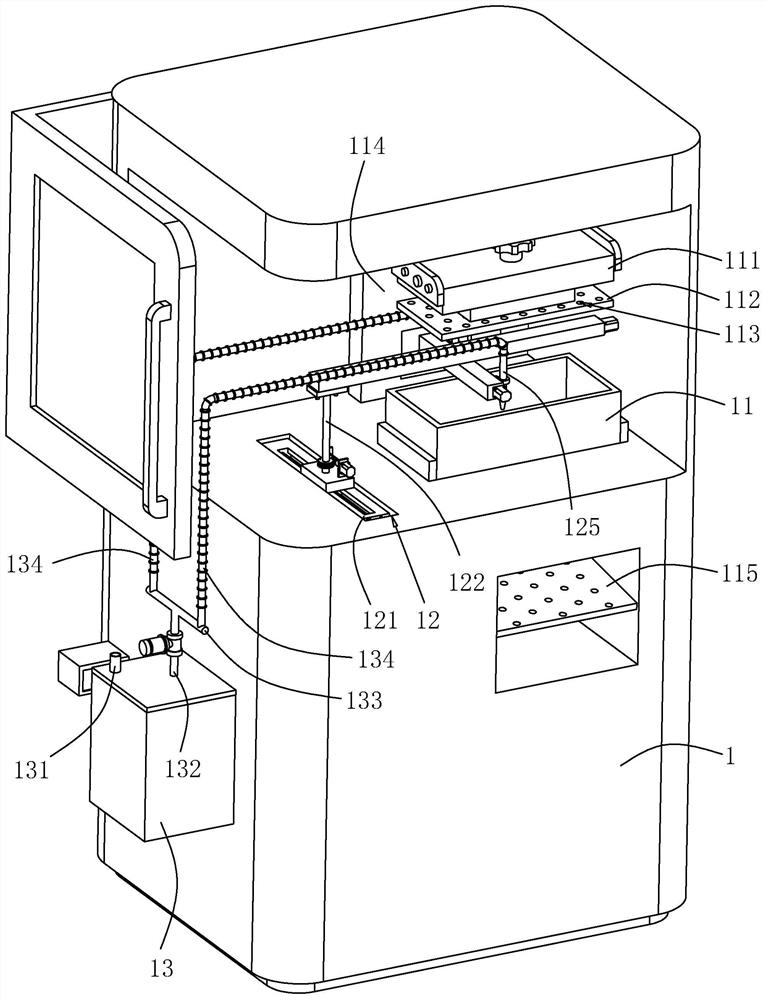

[0039] The following is attached Figure 1-4 The application is described in further detail.

[0040] The embodiment of the present application discloses a 3D printer for metal dentures. refer to figure 1 , a 3D printer for metal dentures, comprising a body 1, a liquid tank 11 is arranged on the body 1, a platform plate 111 is arranged on the body 1 and above the liquid tank 11, and a molding is provided on the surface of the platform plate 111 facing the liquid tank 11 Platform 112, a plurality of adhesion holes 113 are provided on the forming platform 112, and a platform driving device 114 for driving the forming platform 112 toward or away from the liquid tank 11 is provided on the body 1. In this embodiment, the platform driving device 114 is set In other embodiments, the platform driving device 114 can be replaced by a hydraulic cylinder; a surface light source 115 is arranged on the body 1 and directly below the liquid tank 11 .

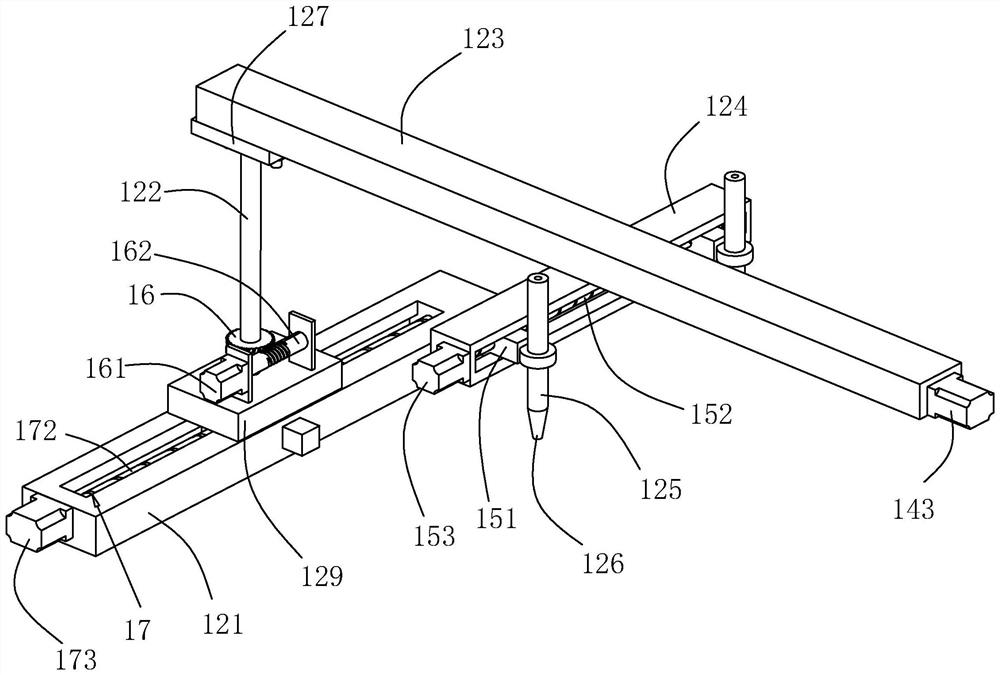

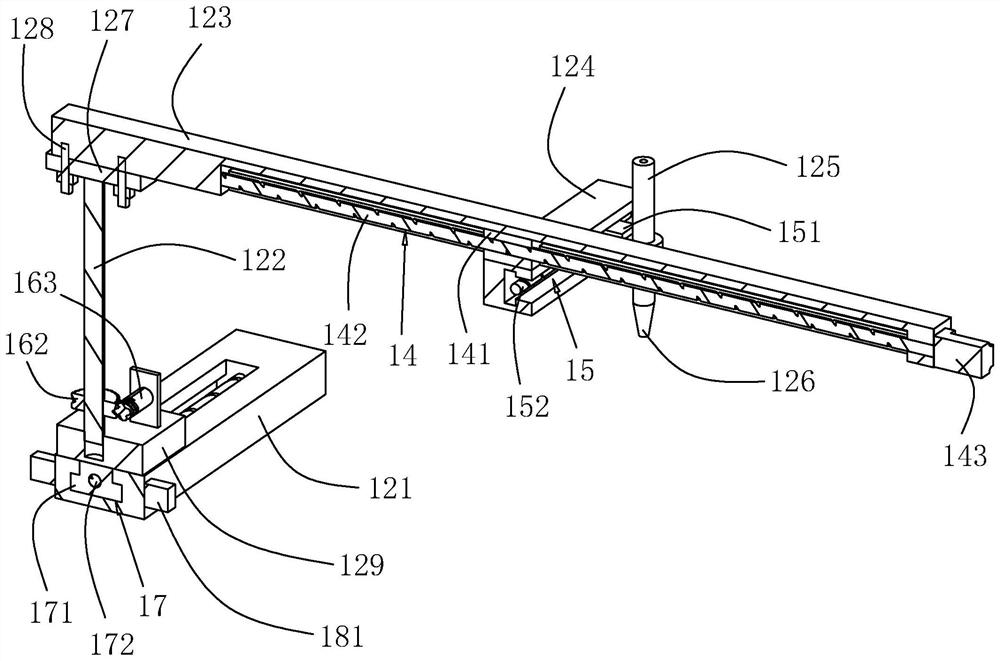

[0041] combine figure 1 and figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com