Separated double-material mixing dropper bottle and assembling method

A dropper bottle and separate type technology, which is applied in the field of separate double-material mixing dropper bottle and assembly, and can solve problems such as complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The positional relationship used in the present invention, such as "up, down, front, back", etc., is only for the convenience of those of ordinary skill in the art to understand the technical solution of the present invention, and does not limit the technical solution of the present invention.

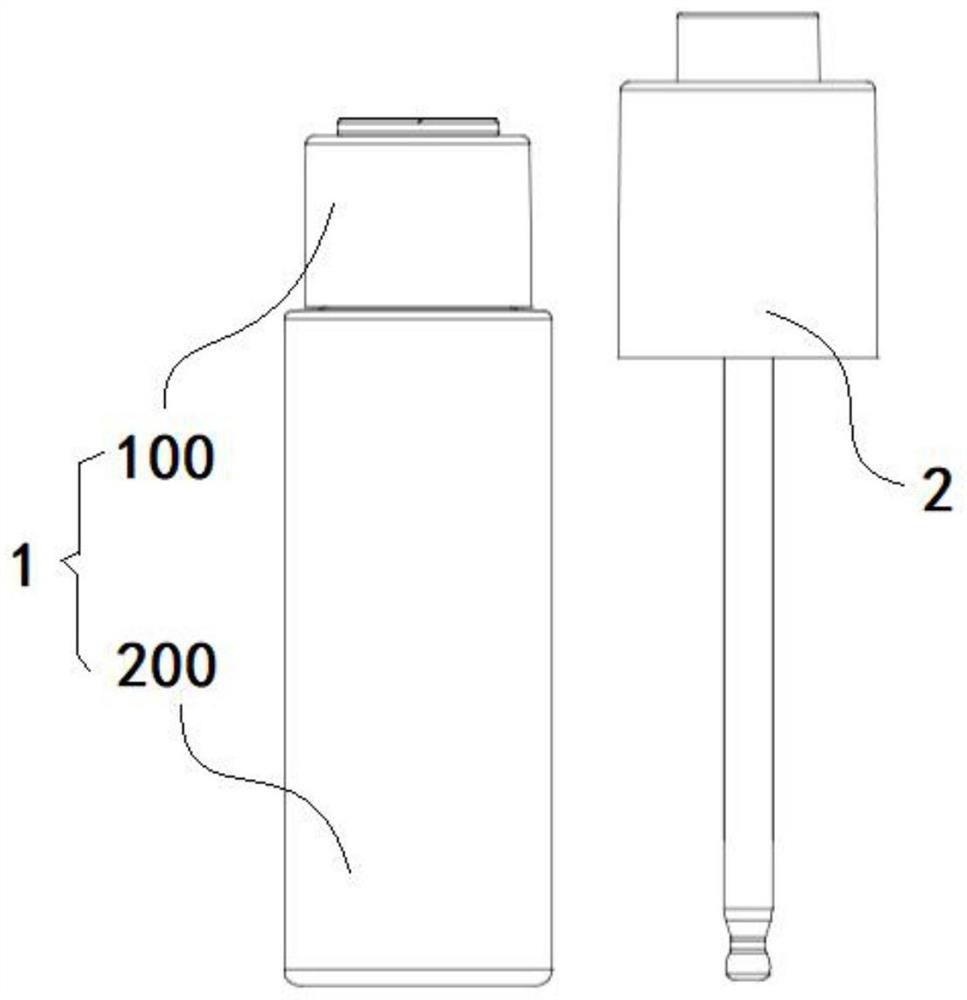

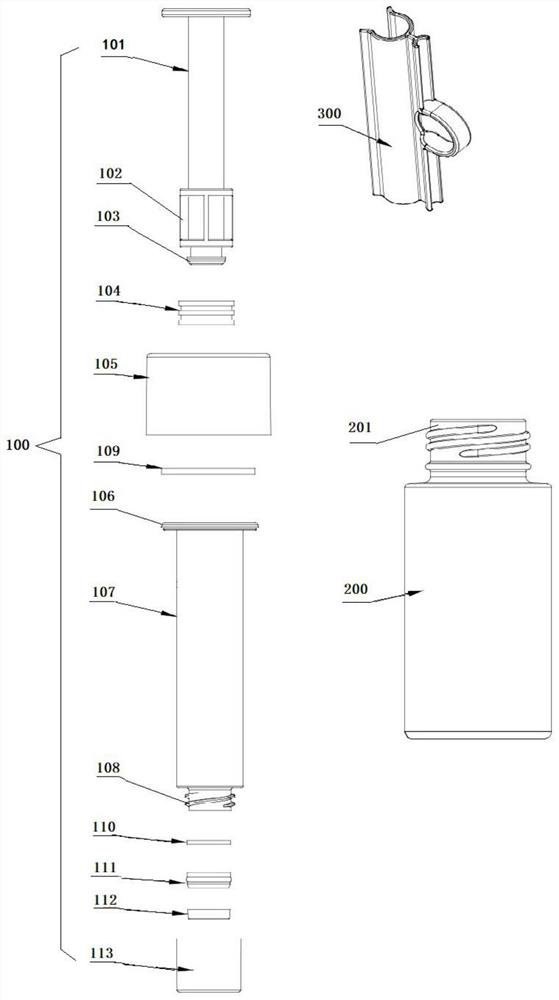

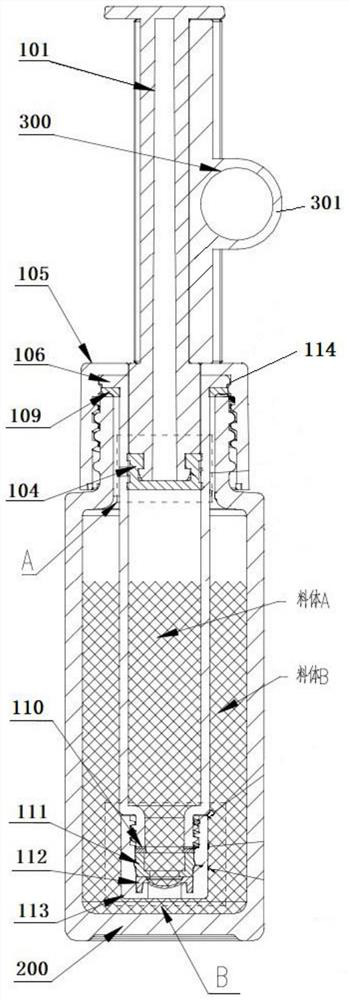

[0054] Such as figure 1 As shown, the present invention relates to a dropper bottle, the first finished product 1 and the second finished product 2 are composed, the first finished product 1 is made up of a bottle cap 100 and a bottle body 200, the bottle cap 100 includes a piston and a screw cap, the piston The lower part is a one-way valve; the dropper bottle is mainly used for packaging two kinds of materials, which can be manually mixed, and the inner tank of the piston is filled with material A, and the bottle body 200 is filled with material B, and the bottle cap 100 and The bottle body 200 is fixed and sealed to keep the activity of the two materials.

[0055] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com