Mechanical arm for unstacking and stacking containerized goods

A technology of manipulators and goods, applied in the field of manipulators, can solve the problems of low work efficiency and high production cost of unpacking and palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

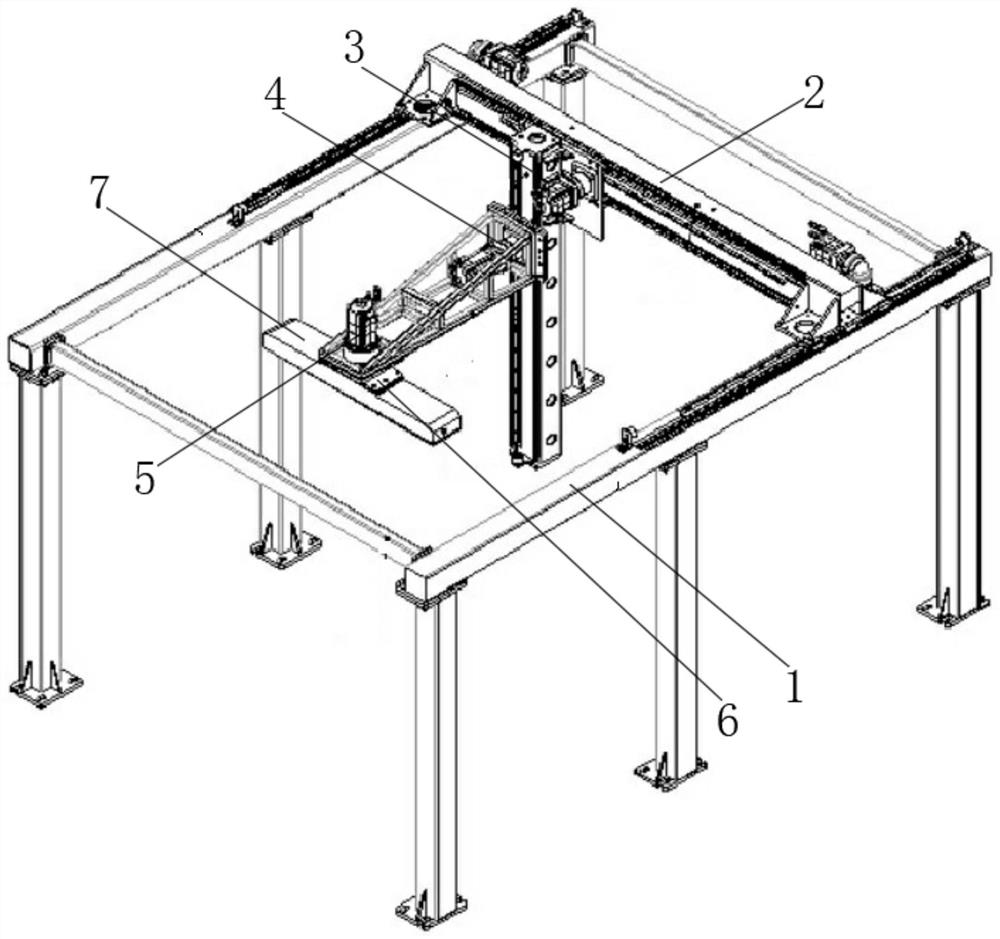

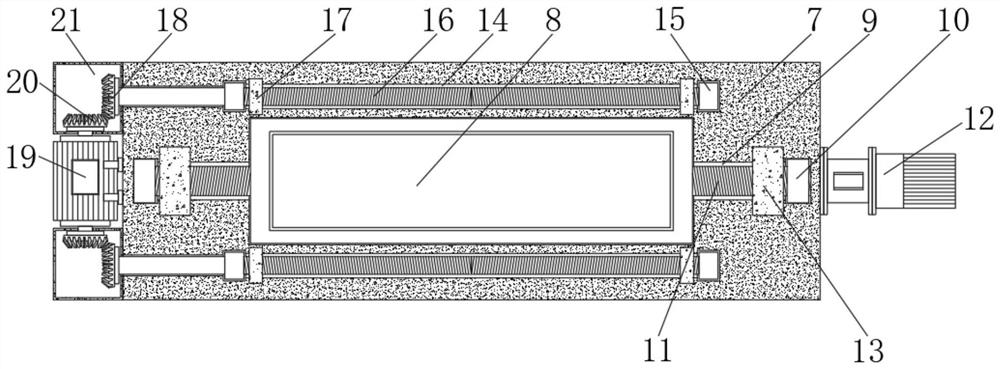

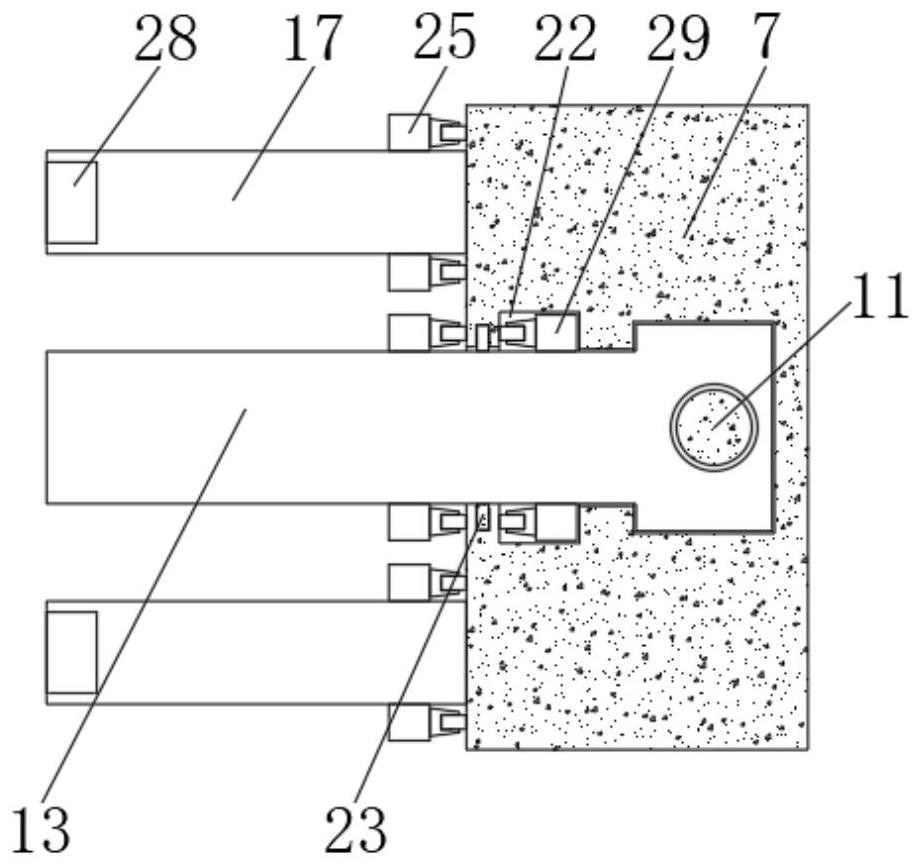

[0026] see Figure 1-5 , a containerized cargo depalletizing manipulator, comprising a bracket 1, the top of the bracket 1 is provided with a first displacement mechanism 2, the first displacement mechanism 2 can move forward and backward along the truss at the top of the bracket 1, the first displacement mechanism 2 The front side is provided with a second displacement mechanism 3, and the second displacement mechanism 3 can move left and right along the fron...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap