Solid-liquid two-phase separation type anaerobic digestion equipment

An anaerobic digestion and phase separation technology, applied in biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve problems such as long-term separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

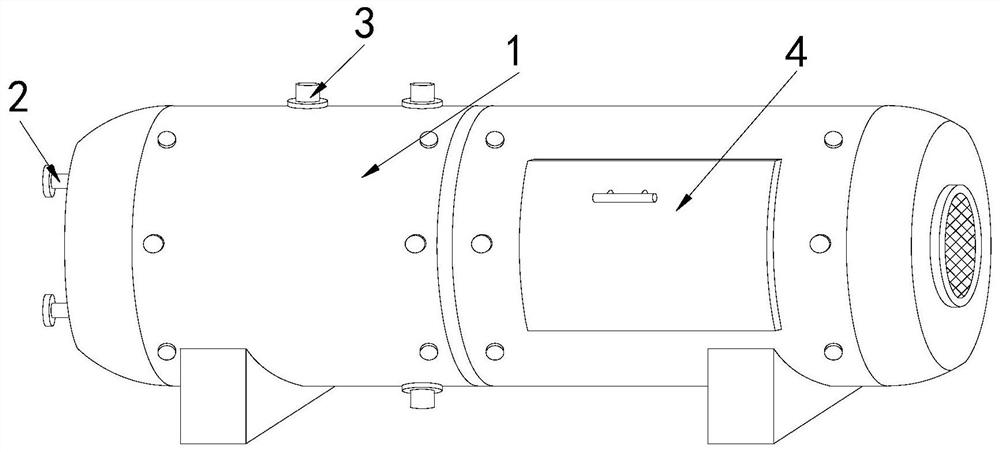

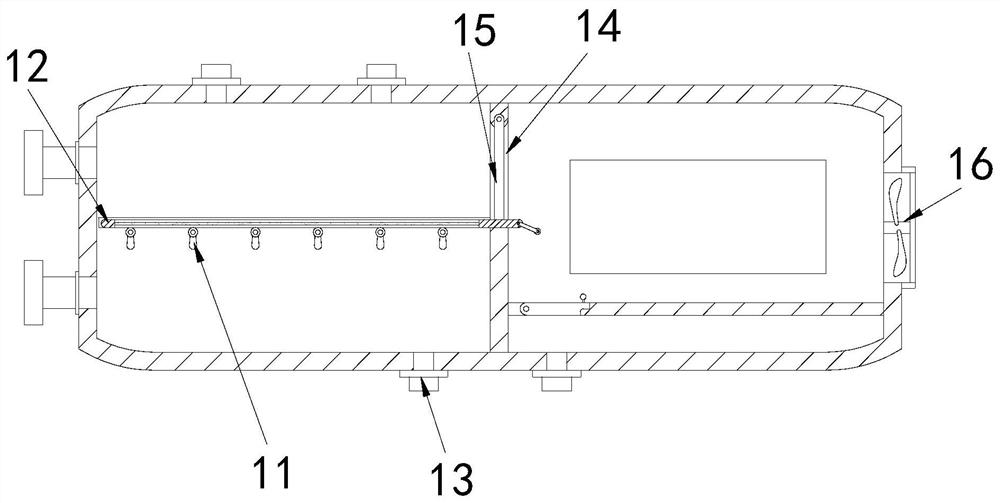

[0024] Example 1: Please refer to Figure 1-Figure 4 , the specific embodiments of the present invention are as follows:

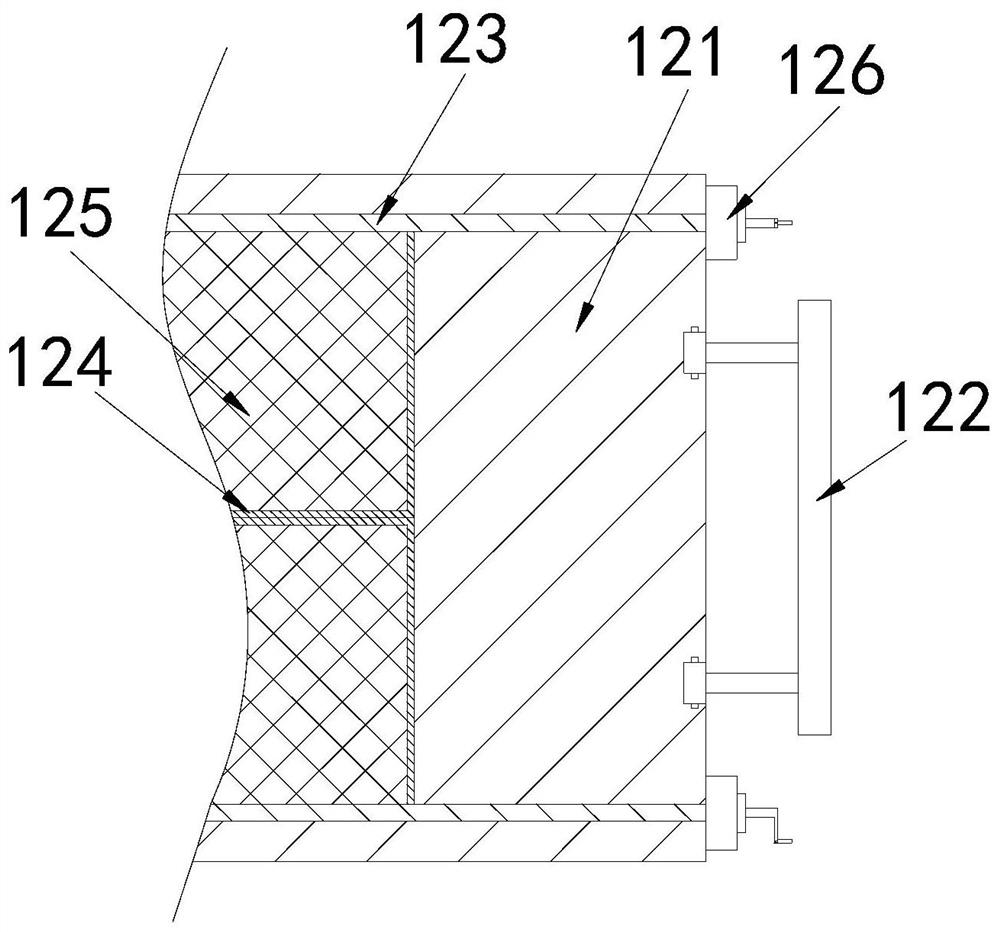

[0025] Its structure includes a main body 1, a feed port 2, an exhaust port 3, and a box door 4. The side end of the main body 1 is provided with a feed port 2, and there are two exhaust ports 3, which are respectively located on the main body 1. The two ends of the top of the box door 4 are provided with two, and they are engaged with the front and rear ends of the main body 1 respectively. The main body 1 includes a sliding block 11, a filter device 12, a sewage outlet 13, a partition 14, plate 15, hot air blower 16, the sliding block 11 is provided with more than five, and is installed laterally at both ends inside the main body 1, the filter device 12 is installed laterally on the upper end surface of the sliding block 11, and the sewage outlet 13 is set At the bottom of the sewage outlet 13 , the partition 14 is located in the middle of the main body...

Embodiment 2

[0029] Example 2: Please refer to Figure 5-Figure 7 , the specific embodiments of the present invention are as follows:

[0030] The partition plate 15 includes an engaging shaft b1, a slot b2, a mounting groove b3, a tension spring b4, a lower top block b5, and a sealing layer b6. The engaging shaft b1 is arranged on the top of the partition plate 15, so that The cutout b2 is located at the rear end of the partition plate 15, the installation groove b3 is located at the inner bottom of the partition board 15, the tension spring b4 is installed inside the installation groove b3, and the lower top block b5 is clamped fit in the installation groove b3, the sealing layer b6 is attached to the front end surface of the partition plate 15, and the tension spring b4 is movably matched with the lower top block b5, which is beneficial to pull the partition plate 15 when closing The extension spring b4 resets and drives the lower top block b5 to move downward, so that the sealing laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com