Limiting anti-overturning device of bridge aerial work platform supporting system and construction method

A technology for aerial work platforms and support systems, which is applied in the field of devices for preventing the support system of bridge aerial work platforms from overturning, and can solve problems such as high installation risks, high installation difficulties, and inability to guarantee personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

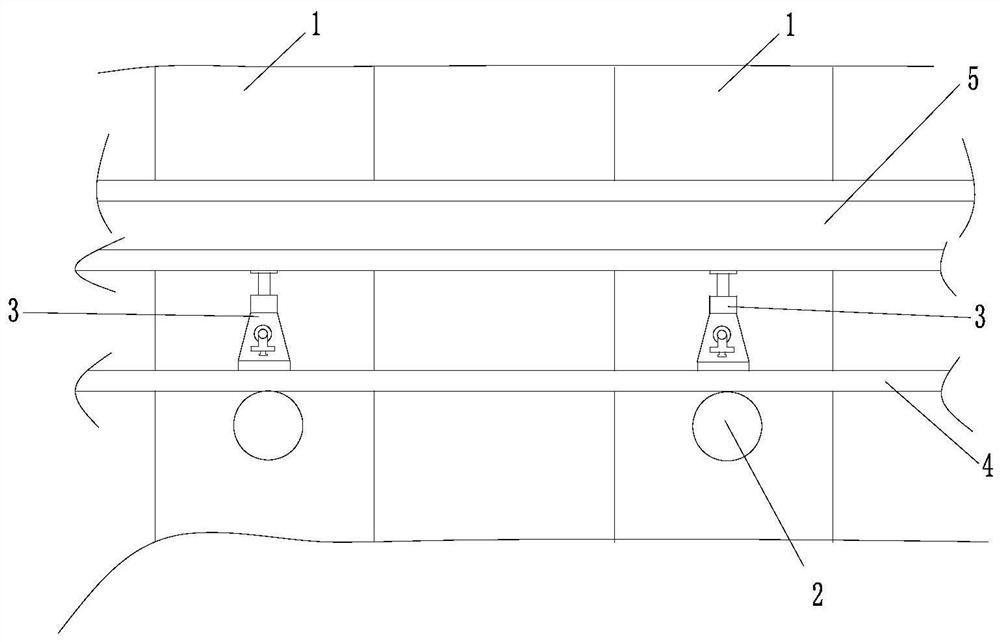

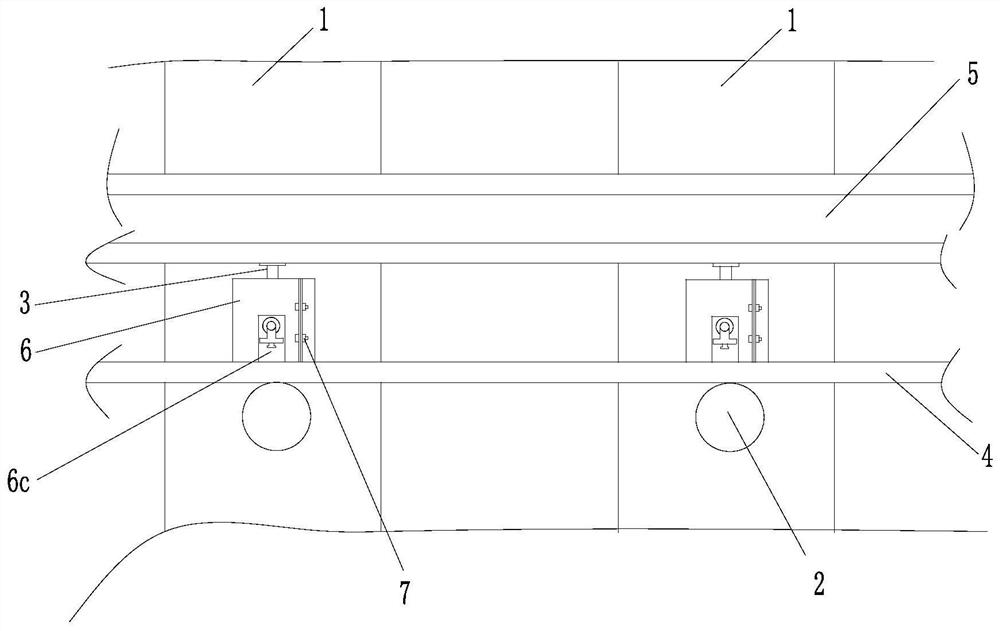

[0032] combine figure 2 — image 3 As shown, a limit anti-overturning device for the support system of a bridge aerial work platform, the piercing rod 2 is horizontally installed on the pier 1, the jack 3 is vertically placed on the channel steel 4 above the piercing rod 2, and the main body of the platform is above the jack 3. Beam 5.

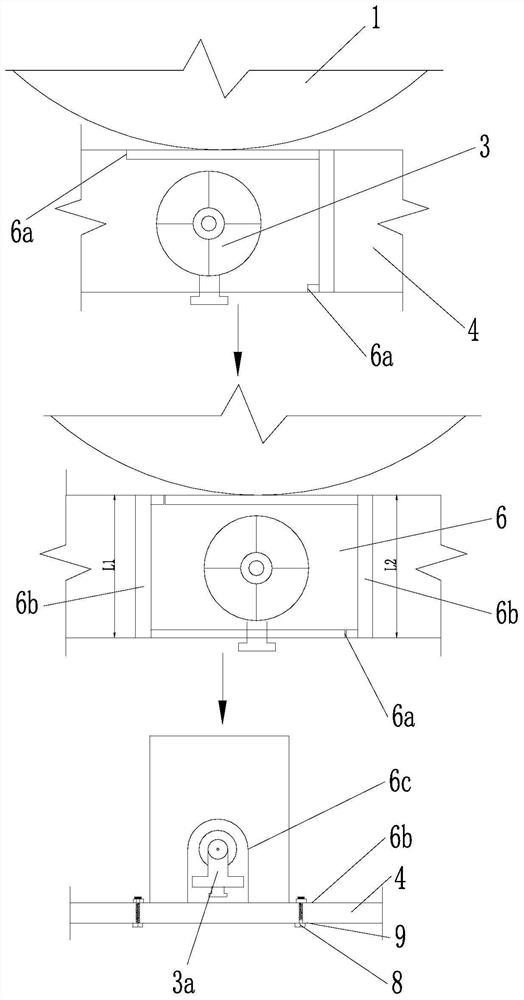

[0033] The anti-overturning box 6 adopts two halves to buckle and encircle and lock and fix it into a rigid box, and the main body of the jack 3 is covered therein, and the top of the jack 3 passes through the anti-overturning box 6 and is pressed against the bottom of the platform girder 5 .

[0034] Preferably, the top and bottom of the anti-overturning box 6 are open, and the cross-sections of the two buckled halves are "L"-shaped respectively, and are made of bent steel plates of 10±5mm, preferably 10mm. The buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com