Epoxy floor construction coating machine

A technology of epoxy floor and coating machine, which is applied in construction, building structure, etc., can solve problems such as difficulty in meeting paint thickness requirements, excessive overflow, and inability to meet coating requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

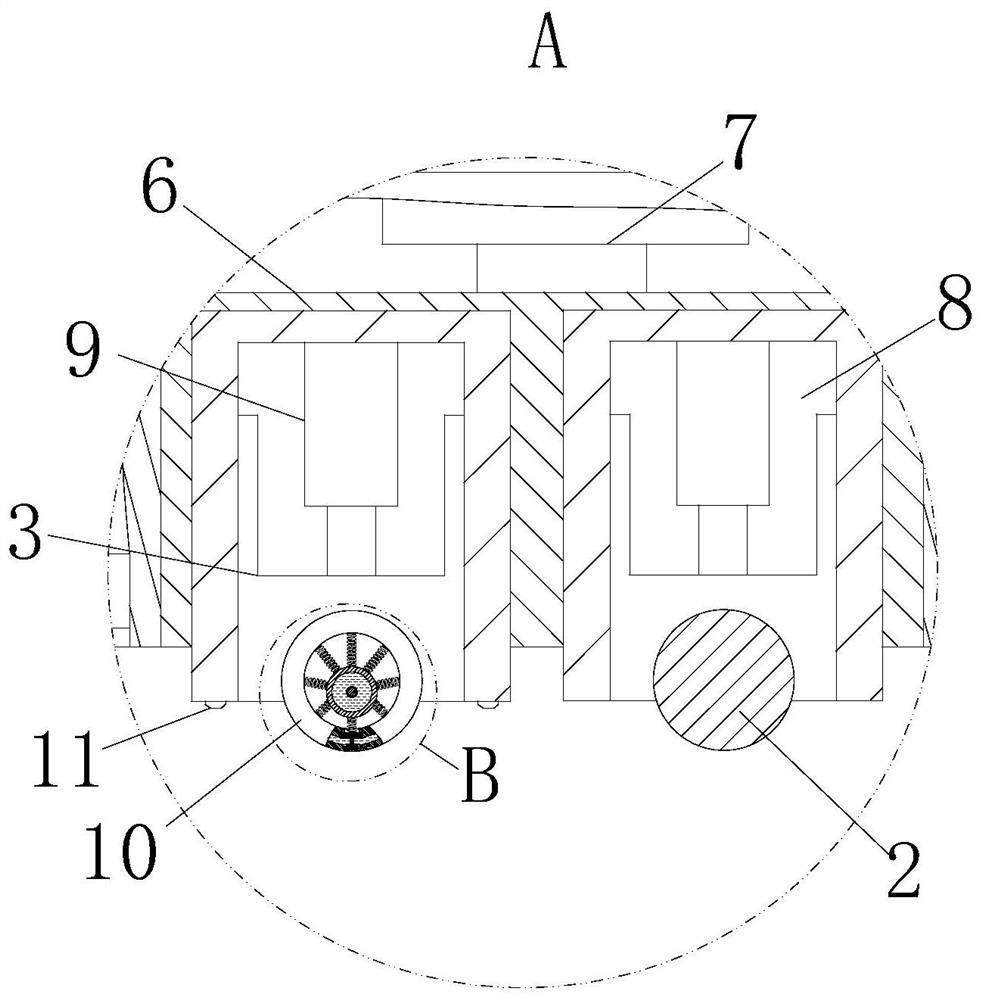

[0029] As an embodiment of the present invention, the inside of the guide cavity 16 is fixedly connected with the stirring rod 17 at the axial position of the moving column 15; the inside of the stirring rod 17 is provided with a heating chamber; the inside of the heating chamber is fixedly connected There is a heating rod 18; during work, by setting the stirring rod 17 inside the guide cavity 16, the stirring of the epoxy paint 5 can be promoted on the one hand, and the internal heating rod 18 of the stirring rod 17 can convectively flow into the inside of the guide cavity 16. The epoxy paint 5 is heated to promote the softening of the epoxy paint 5, improve the fluidity of the epoxy paint 5, and reduce the flow resistance of the epoxy paint 5.

[0030] As an embodiment of the present invention, the inner surface of the cavity 14 is provided with uniformly arranged guide grooves; inside the guide grooves, guide blocks 19 are slidably connected; between the guide blocks 19 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com