Prestressed full-length anchoring hollow grouting anchor rod with auxetic effect

A technology of full-length anchoring and grouting bolts, applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of long cement mortar consolidation time, reduced normal stress, and slurry leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

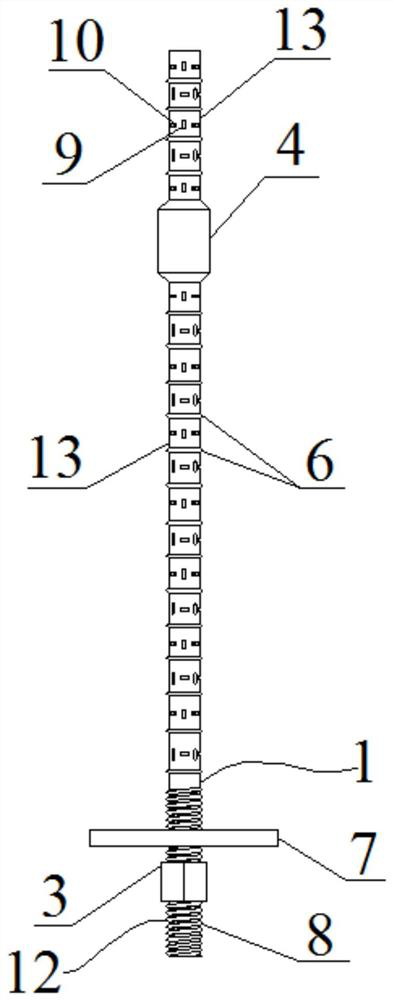

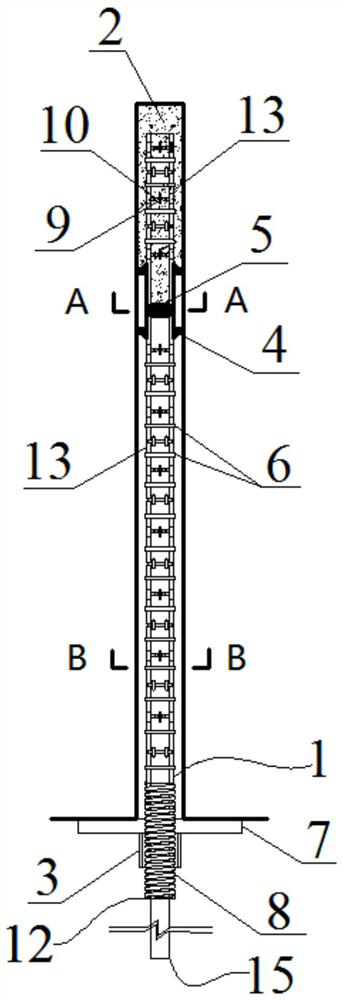

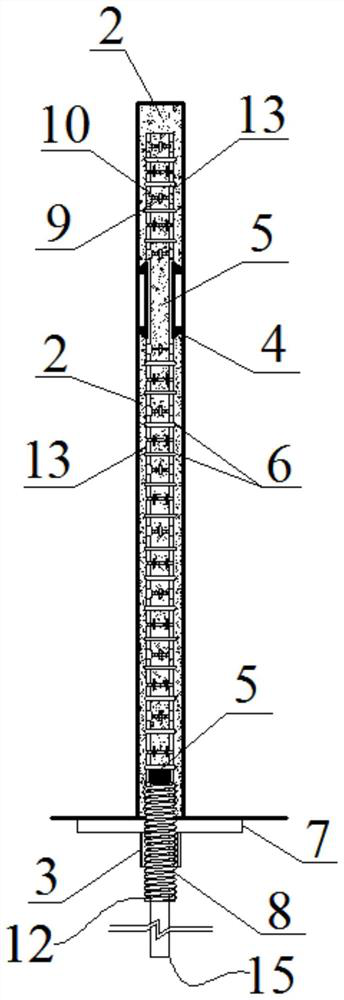

[0028] Such as Figure 1 to Figure 10 As shown, a prestressed full-length anchoring hollow grouting anchor with auxetic effect, including a rod body 12, a tray 7, a nut 3 and a centering ring 4;

[0029] The inside of the rod body 12 is provided with an axially through central grouting hole 14; the rod body 12 is composed of a threaded section 8 at the end and a main body section 1 outside the threaded section 8; the outside of the threaded section 8 is provided with External threads; the surface of the main body section 1 is uniformly fixedly connected with a plurality of protruding rib rings 6 along the length direction, and the part between adjacent protruding rib rings 6 forms a communication part 13; the protruding rib rings 6 The outer diameter is smaller than the diameter of the borehole to be constructed; each connecting portion 13 is provided with a plurality of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com