Boiler with temperature instrument

A technology for instrumentation and temperature detectors, applied in fluid heaters, lighting and heating equipment, electromagnetic audible signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

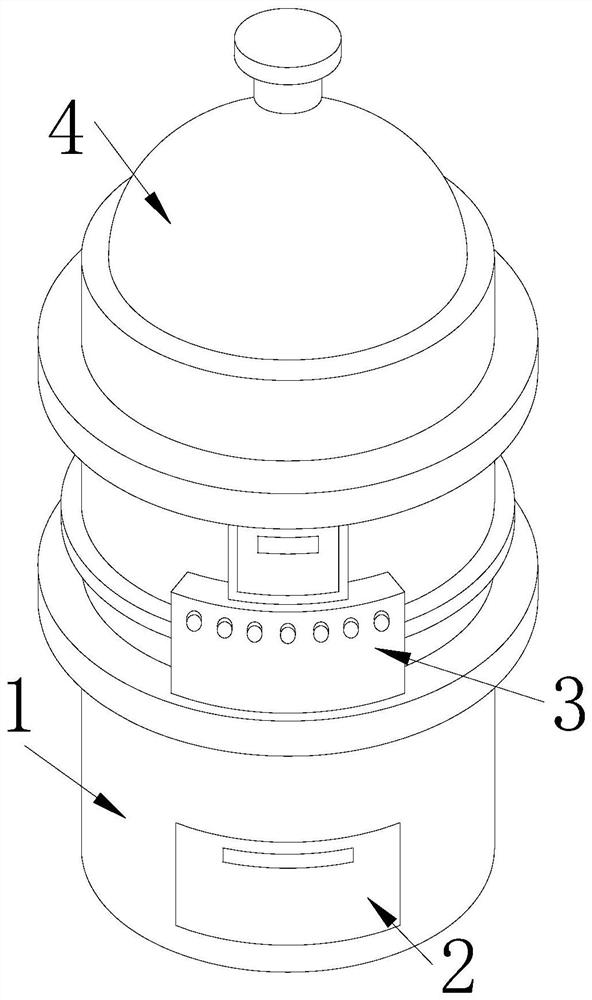

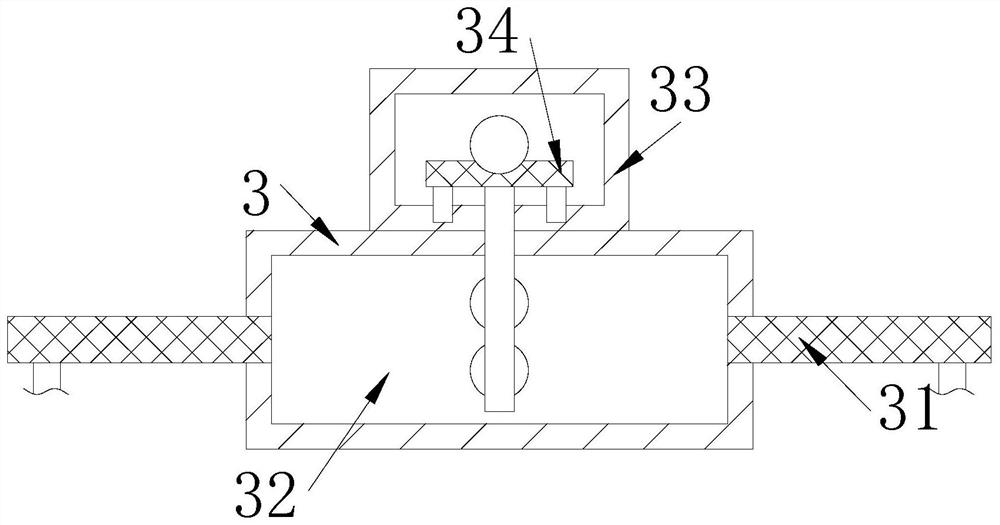

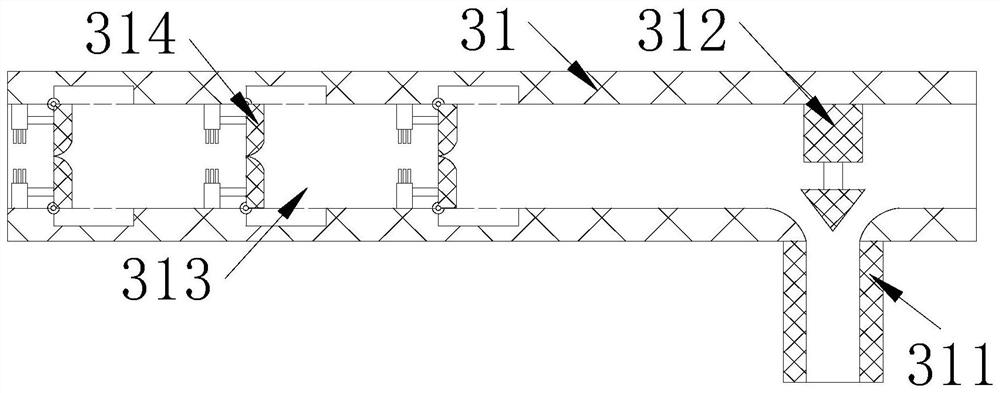

[0029] The invention provides a boiler with temperature instrumentation, the structure of which includes a boiler 1, a heating cabinet 2, a temperature detection ring 3, and an upper cover 4. 3 is nested on the outer surface of the boiler 1, the upper cover 4 is connected to the top of the boiler 1 through movable engagement, the temperature detection ring 3 includes a water guide pipe 31, a transfer box 32, an isolation box 33, and a temperature detector 34. The water guide pipe 31 is horizontally welded on the left and right sides of the temperature detection ring 3, the transfer box 32 is embedded inside the temperature detection ring 3, the bottom of the isolation box 33 is connected to the upper surface of the temperature detection ring 3 by welding, and the temperature detector 34 is embedded in the temperature detection ring 3, and the bottom of the temperature detector 34 penetrates the bottom of the isolation box 33 and is placed inside the transfer box 32. The water g...

Embodiment 2

[0035] The invention provides a boiler with temperature instrumentation, the structure of which includes a boiler 1, a heating cabinet 2, a temperature detection ring 3, and an upper cover 4. 3 is nested on the outer surface of the boiler 1, the upper cover 4 is connected to the top of the boiler 1 through movable engagement, the temperature detection ring 3 includes a water guide pipe 31, a transfer box 32, an isolation box 33, and a temperature detector 34. The water guide pipe 31 is horizontally welded on the left and right sides of the temperature detection ring 3, the transfer box 32 is embedded inside the temperature detection ring 3, the bottom of the isolation box 33 is connected to the upper surface of the temperature detection ring 3 by welding, and the temperature detector 34 is embedded in the temperature detection ring 3, and the bottom of the temperature detector 34 penetrates the bottom of the isolation box 33 and is placed inside the transfer box 32. The water g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com