Fluidization classification equipment and method

A technology of equipment and grading chamber, applied in the field of fluidized grading equipment, can solve the problems of affecting grading effect, poor grading accuracy of concentration funnel, blockage of underflow discharge port, etc., achieving simple method and structure, facilitating automatic discharge, and preventing sedimentary blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

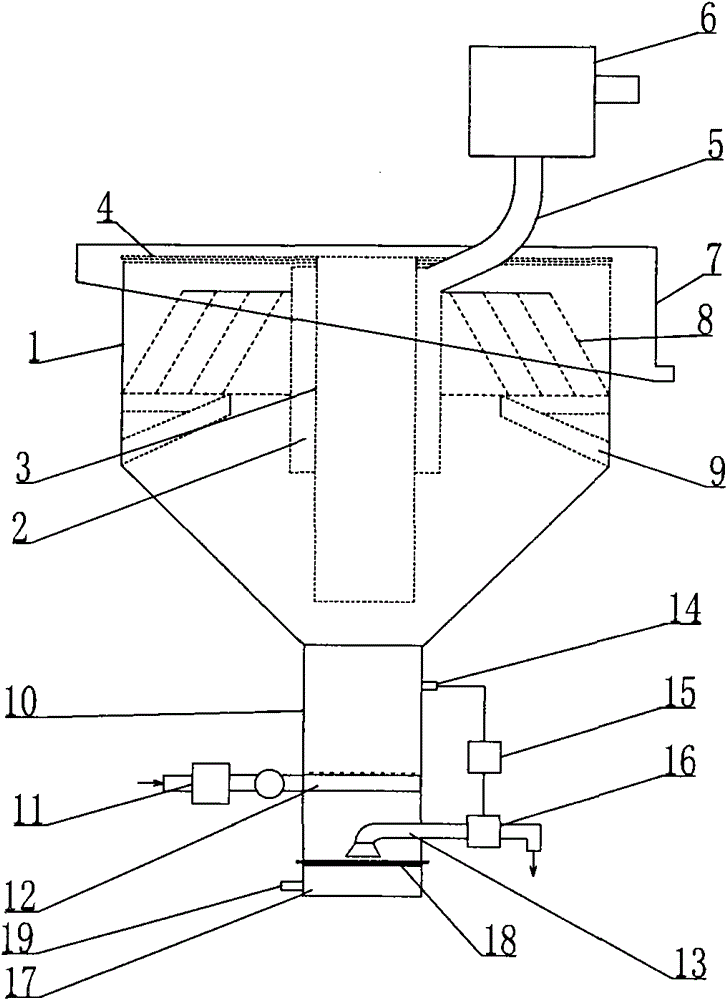

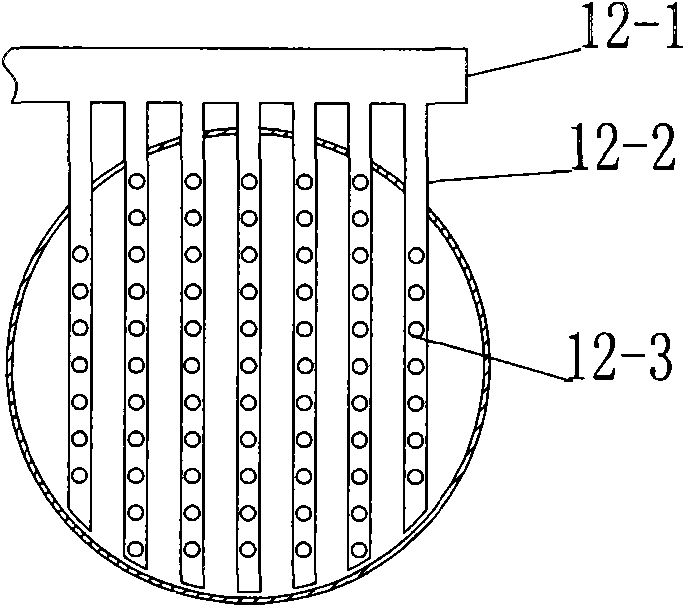

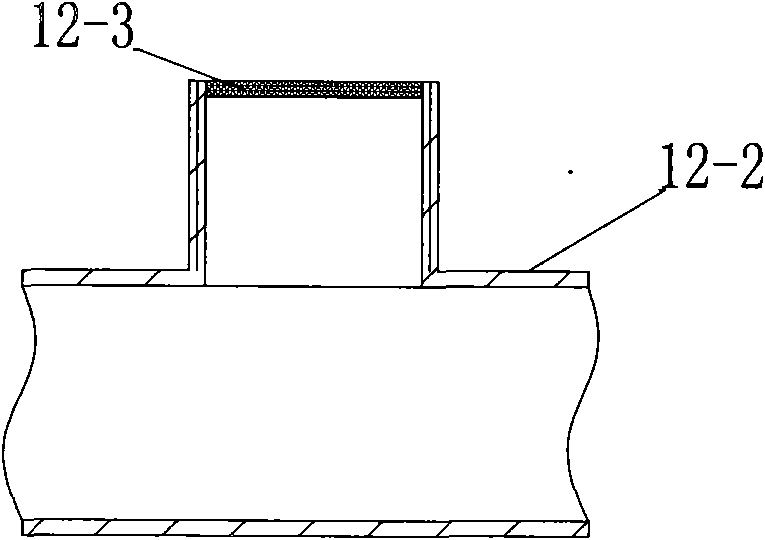

[0019] like figure 1 As shown, the fluidized grading equipment of the present invention mainly consists of a sedimentation grading chamber 1, a center feed casing 2, a center pipe 3, an overflow tank 4, a tangential feed pipe 5, a feed buffer barrel 6, an overflow Collection tank 7, conical inclined orifice plate 8, conical inclined orifice plate support 9, fluidized classification chamber 10, pulsating water flow generator 11, pulsating water flow distributor 12, coarse-grained material discharge pipe 13, sensor 14, Programmed controller 15, coarse-grained material discharge automatic control actuator 16, coarse-grained material fluidization chamber 17, water distribution plate 18, and water supply pipe 19 constitute. The upper part of the sedimentation classification chamber 1 is a cylinder, and the lower part is a cone. The lower part is connected to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com