AGV tractive trolley

A technology of towing trolleys and traction devices, which is applied in the field of intelligent storage and logistics vehicles, can solve the problems of small transfer space, restrictions, and long time consumption, and achieve the effect of facilitating automatic discharge and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings. However, this embodiment does not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to this embodiment are included in the protection scope of the present invention.

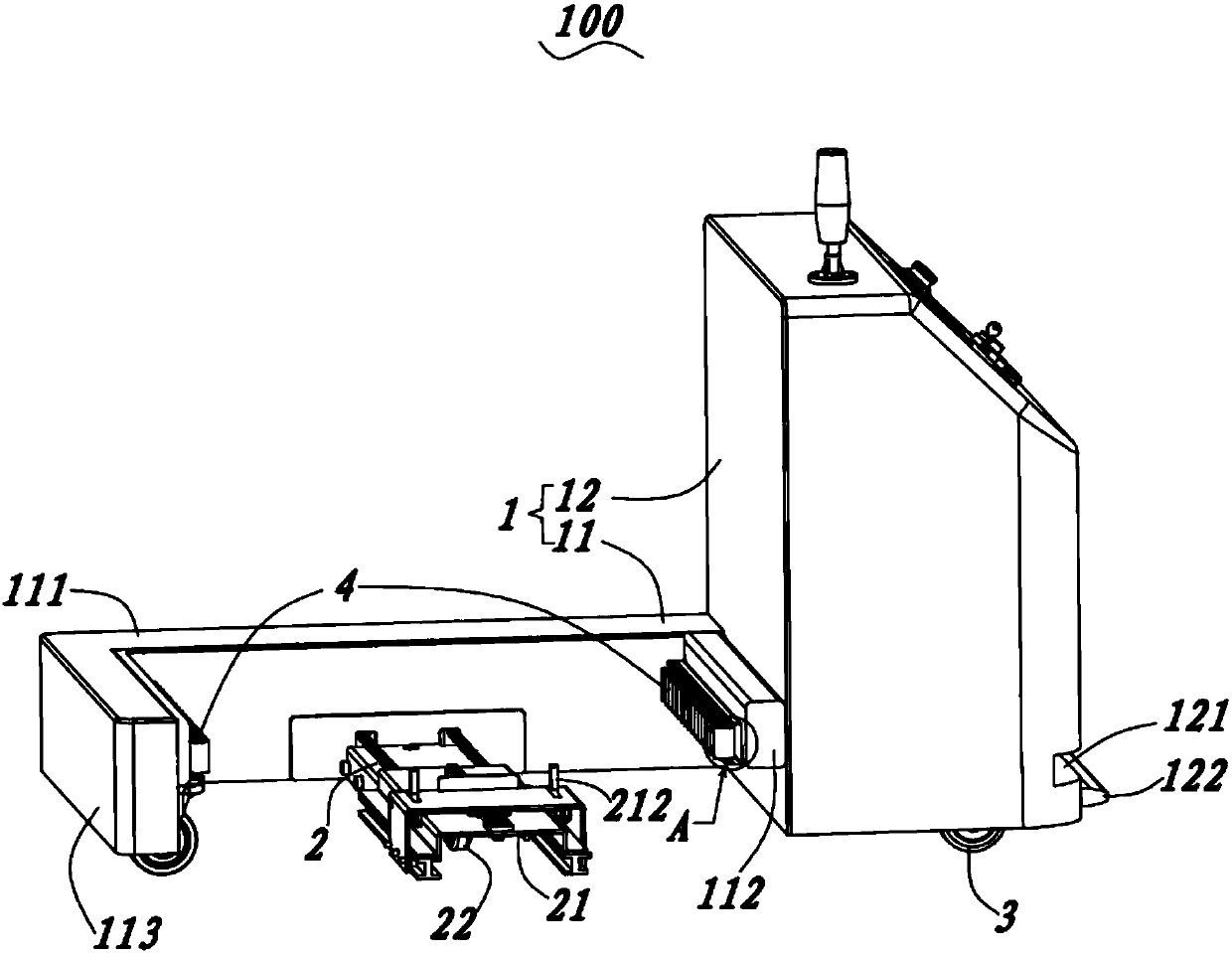

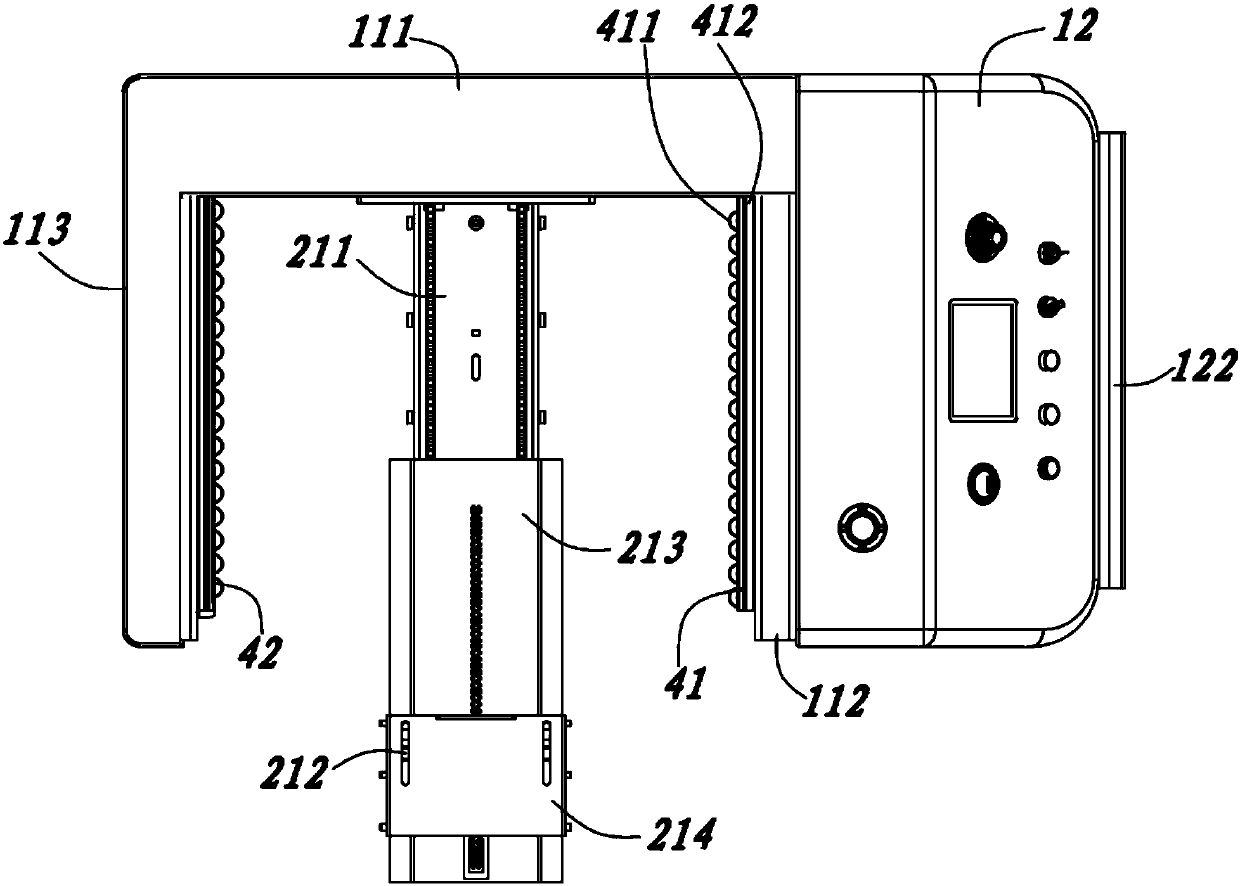

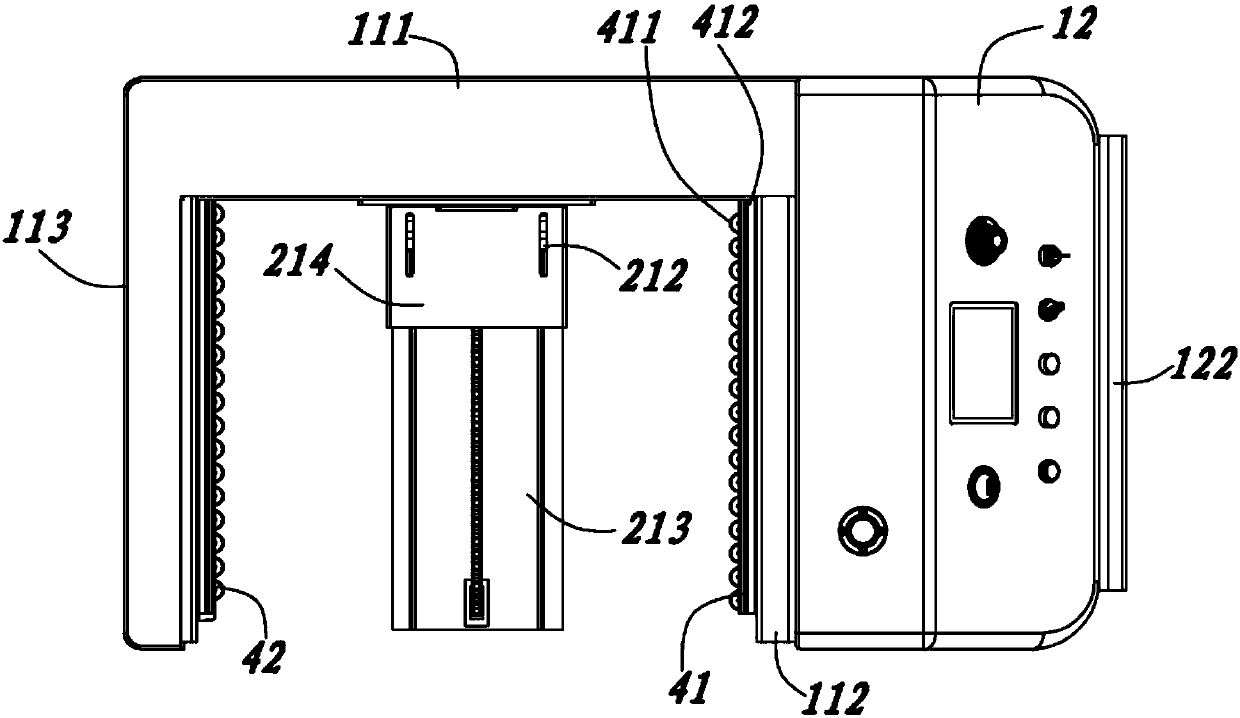

[0022] see figure 1 It is a schematic structural diagram of the AGV traction trolley 100 provided by the present invention. The AGV traction trolley 100 includes a body body 1 , a traction device 2 installed on the body body 1 , and a plurality of road wheels 3 arranged under the body body 1 . The vehicle body body 1 is formed with a traction area 10 opening laterally outward; the traction device 2 has a hanging assembly 21 extending laterally. to combine figure 2 and image 3 As shown, the hanging assembly 21 has a first state protruding laterally beyond the opening of the traction area 10 and a second st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com