Multi-flow-direction impeller box assembly and water meter with the same

A technology of impeller box and multi-flow direction, which is applied in the field of multi-flow impeller box components and water meter parts, which can solve the problems of time-consuming, labor-intensive, high cost, and affecting the measurement accuracy and measurement range of water meters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Aiming at the deficiencies in the prior art, the present invention provides an impeller box assembly, which is actually an impeller box assembly that can adjust the flow rate of the water meter and the water inlet mode, specifically by adjusting the installation position of the adjustment plate of the impeller box assembly Changing the flow area of the water inlet fluid and changing the water inlet mode by replacing the adjusting plate in the impeller box assembly can effectively realize the free switching between the rotor-type water meter and the screw-type water meter, which is conducive to correcting the amplitude of the full-curve performance error of the water meter It also helps to improve the measurement accuracy of the water meter and expand the measurement range of the water meter.

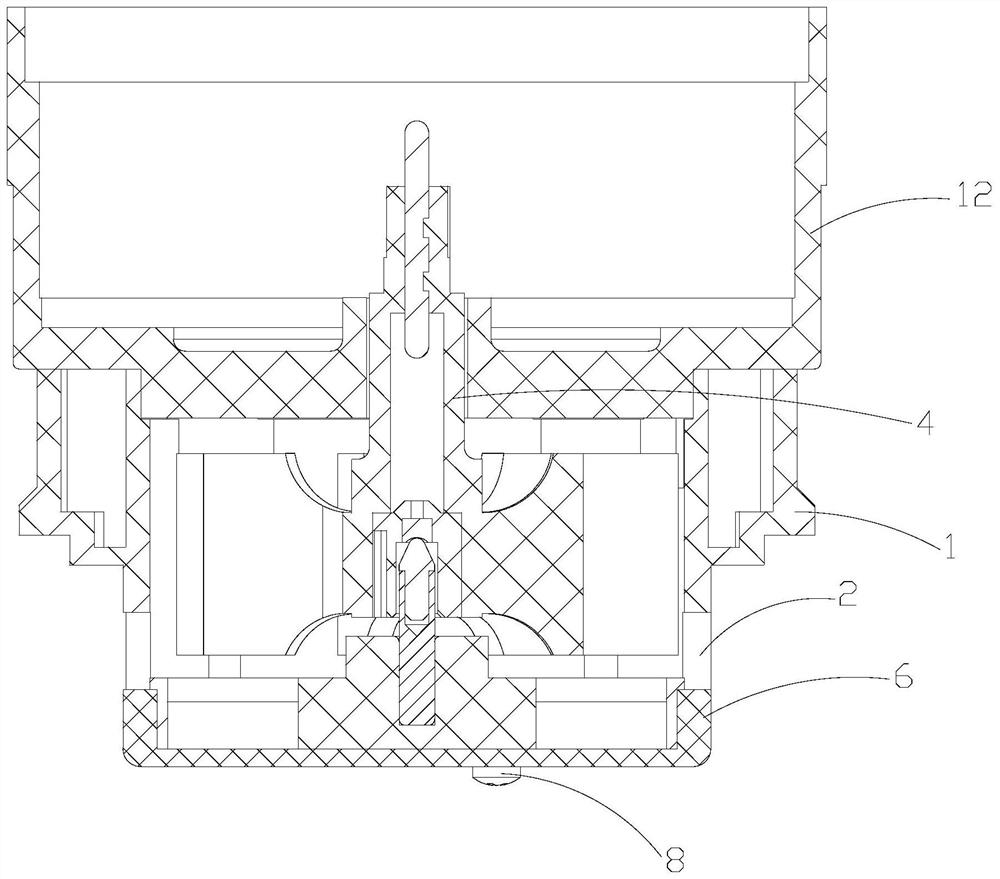

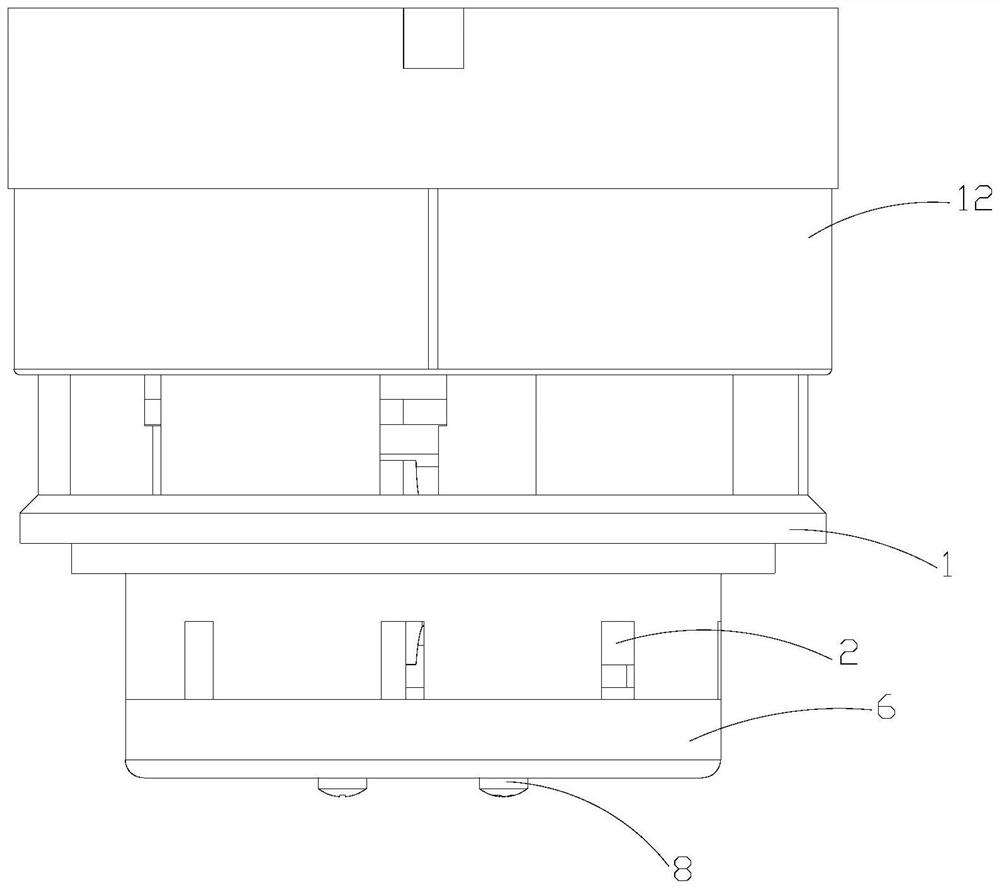

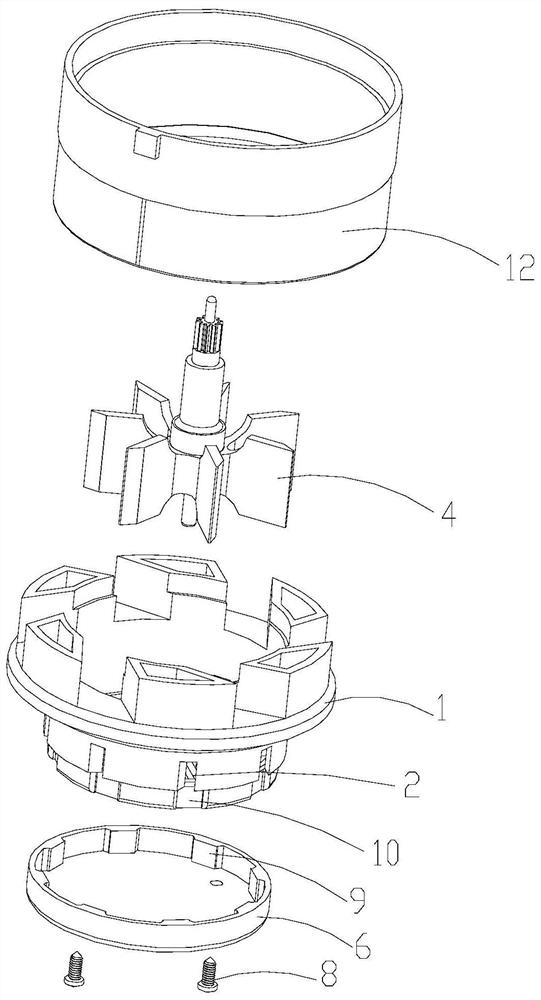

[0034] Such as Figure 1-8 As shown, a multi-flow direction impeller box assembly provided in the embodiment of the present invention is used to be applied to a water meter to b...

Embodiment 2

[0053] The impeller box 1 of the embodiment of the present invention is provided with clamping blocks 9 , and grooves 10 are provided on the inner walls of the rotor-type adjusting plate 6 and the spiral-wing adjusting plate 7 , and the clamping blocks 9 can be engaged with the grooves 10 . Except that, other content is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com