A multi-directional multi-layer full-diameter fracture core seepage simulation device and its application

A seepage simulation, full-diameter technology, applied in measuring devices, teaching models, educational appliances, etc., can solve the problems of inability to simulate complex seepage conditions in the formation, and does not consider the multi-directional and multi-layered radial seepage conditions, so as to avoid secondary damage and operation inconvenience, accurate evaluation, and high reference value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below with reference to the accompanying drawings, but the present invention is not limited to the following embodiments.

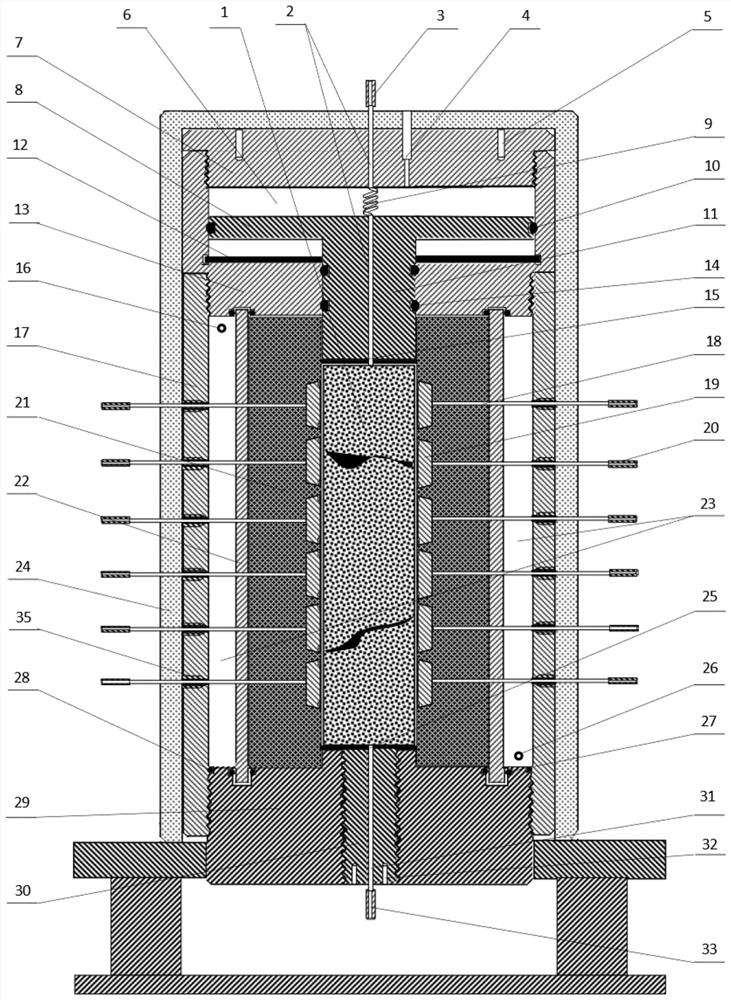

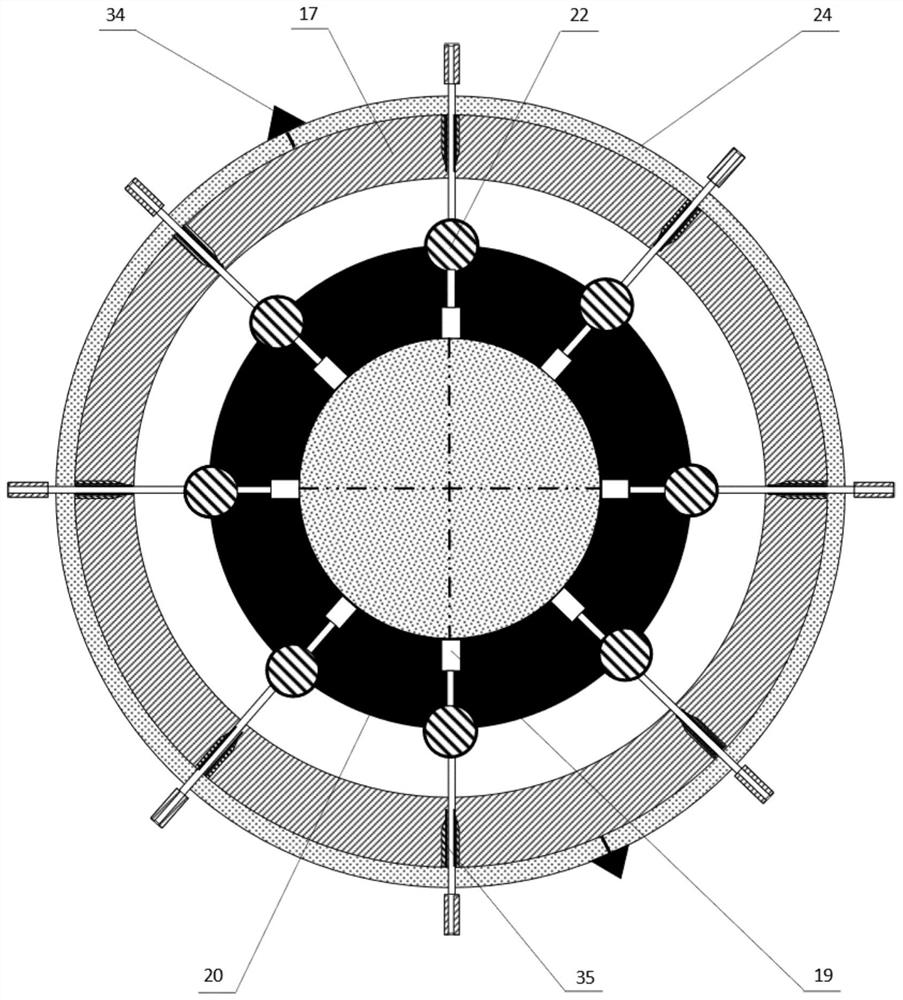

[0063] The multi-directional multi-layer full-diameter fractured core seepage simulation device provided by the present invention, its overall structure schematic diagram is as follows figure 1 As shown (section view in the main view direction), it includes a full-diameter fracture core clamping module, a radial multi-directional multi-layer seepage injection-production module, an axial seepage injection-production module, and a stress and temperature loading module.

[0064] The full-diameter fracture core clamping module includes a high-pressure rubber sleeve 21 and a holder cylinder 17, and the inner cavity of the high-pressure rubber sleeve 21 serves as a full-diameter fractured core chamber 1 for placing full-diameter fractured core samples. The holder cylinder 17 is sleeved on the outside of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com