Hierarchical fault monitoring method based on mixed characteristic evaluation and subspace decomposition

A technology of subspace decomposition and mixed characteristics, which is applied in the field of hierarchical fault monitoring based on mixed characteristic evaluation and subspace decomposition, can solve the problem of coexistence of Gaussian linear correlation and nonlinear correlation without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

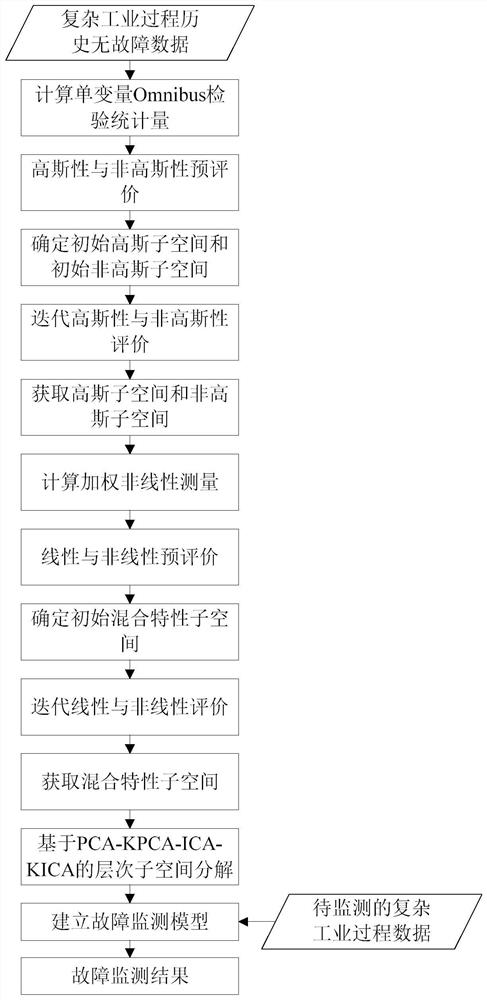

[0101] Such as figure 1 Shown is the flow chart of the method of the present invention.

[0102] Based on the hierarchical fault monitoring method of mixed characteristic evaluation and subspace decomposition, the complex industrial process data is collected, and after the mixed characteristic subspace is obtained, the hierarchical subspace decomposition and hierarchical monitoring strategy based on PCA-ICA-KPCA-KICA is used for fault monitoring. The programming languages used in the program execution steps of the present invention are not limited to MATLAB, Python and the like.

[0103] Concrete steps of the present invention are as follows:

[0104] Step 1 includes the following steps:

[0105] Step 1-1: Collect historical fault-free data of complex industrial processes X=[x 1 ; x 2 ;…;x m ], taking Tennessee Eastman (TE) chemical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com